Preparation method of aluminum silicate crystal whisker enhanced polyether-ether-ketone modified material

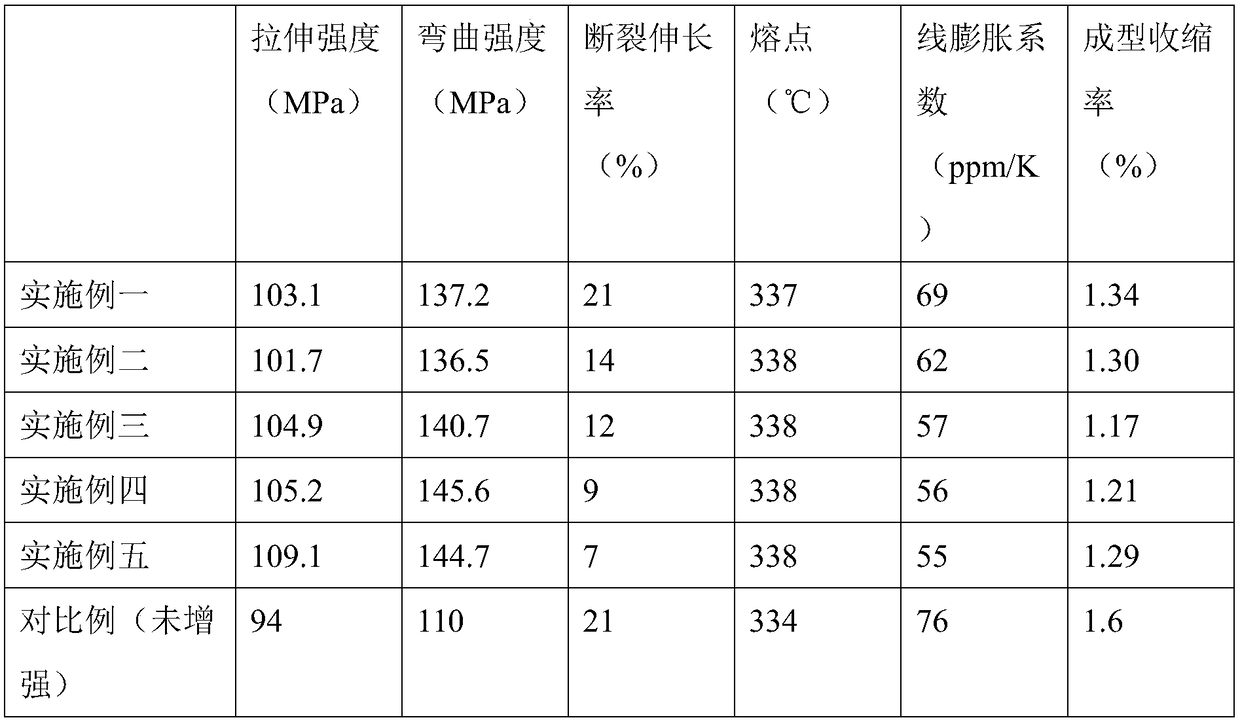

A silicic acid polyether ether ketone coupling agent and a technology of aluminum silicate whiskers, which are applied in the field of preparation of aluminum silicate whiskers reinforced polyether ether ketone modified materials, can solve the problems of large structural differences and the like, and achieve line Effects of increased expansion coefficient, tensile and flexural properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Put 1 part of silicic acid polyetheretherketone coupling agent into a three-necked flask with external stirring, add tetrachloromethane 70 times the mass of the coupling agent to dissolve, and then dry it in vacuum at 140°C for 300 minutes and cool it down Add 95 parts of aluminum silicate whiskers to the above mixture, continue to stir for 460min at a stirring speed of 60r / min, filter and cool, then extract with ethanol for 100min, after filtration, dry the supernatant at 150°C for 700min, and cool to Standby at room temperature;

[0027] 2. Take 10 parts of the dry mixture in step 1 and 70 parts of polyether ether ketone micropowder, put them into an electric heating three-neck flask with magnetic stirring, put in tetrahydrofuran solvent 40 times the total mass of the materials, and ultrasonicate for 100 minutes at room temperature , heated up to 115°C, ultrasonicated for 60 minutes, and the ultrasonicated mixture was filtered, dried, and then taken out for use;

...

Embodiment 2

[0030] 1. Put 2 parts of silicic acid polyether ether ketone coupling agent into a three-necked flask with external stirring, add tetrachloromethane 75 times the mass of the coupling agent to dissolve, and then dry it in vacuum at 150°C for 360 minutes and cool it down Add 98 parts of aluminum silicate whiskers to the above mixture, continue to stir for 480min at a stirring speed of 70r / min, filter, cool, and then extract with ethanol for 120min, after filtration, dry the supernatant at 160°C for 720min, and cool to Standby at room temperature;

[0031] 2. Take 20 parts of the dry mixture in step 1 and 80 parts of polyetheretherketone micropowder, put them into an electric heating three-neck flask with magnetic stirring, put in tetrahydrofuran solvent 45 times the total mass of the materials, and ultrasonicate for 120 minutes at room temperature , heated up to 120°C, ultrasonicated for 60 minutes, and the ultrasonicated mixture was filtered, dried, and then taken out for use; ...

Embodiment 3

[0034] 1. Put 3 parts of silicic acid polyether ether ketone coupling agent into a three-necked flask with external stirring, add tetrachloromethane 80 times the mass of the coupling agent to dissolve, and then dry it in vacuum at 160°C for 400 minutes and cool it down Add 97 parts of aluminum silicate whiskers to the above mixture, continue to stir for 480min at a stirring speed of 80r / min, filter, cool, and then extract with ethanol for 120min, after filtration, dry the supernatant at 160°C for 720min, and cool to Standby at room temperature;

[0035] 2. Take 30 parts of the dry mixture material in step 1 and 90 parts of polyetheretherketone micropowder, put them into an electric heating three-necked flask with magnetic stirring, put in tetrahydrofuran solvent 50 times the total mass of the materials, and ultrasonicate for 120 minutes at room temperature, Raise the temperature to 120°C, sonicate for 70 minutes, filter and dry the sonicated mixture and take it out for use;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com