Supporting leg automatic leveling method with suspended leg recognition function

An automatic leveling and leveling technology, applied in the direction of cranes, etc., can solve the problems of unstressed outriggers, cumbersome procedures, affecting work efficiency, etc., to ensure safe operation, improve leveling efficiency, and strong adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

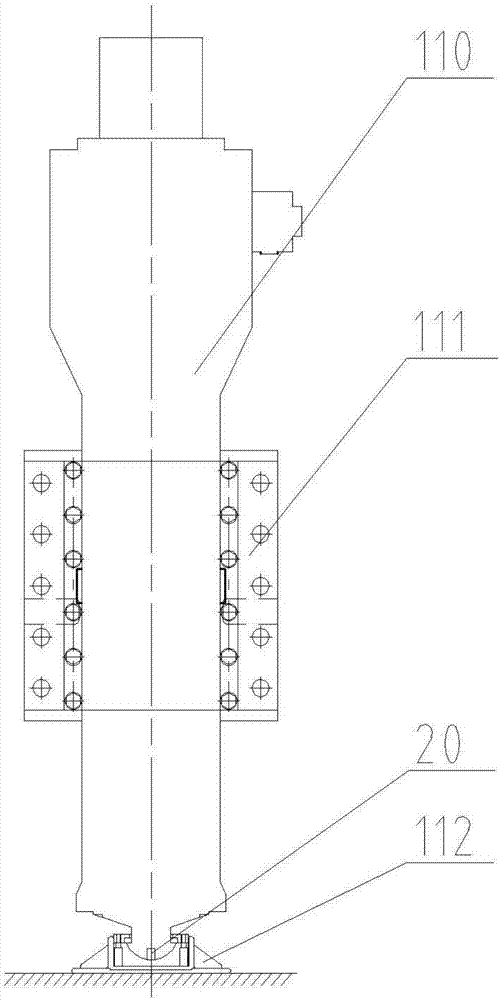

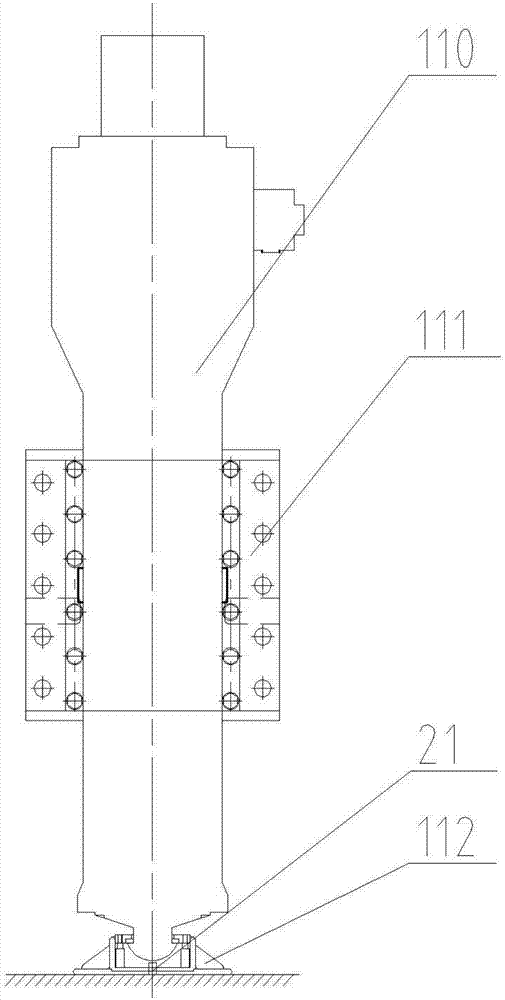

Image

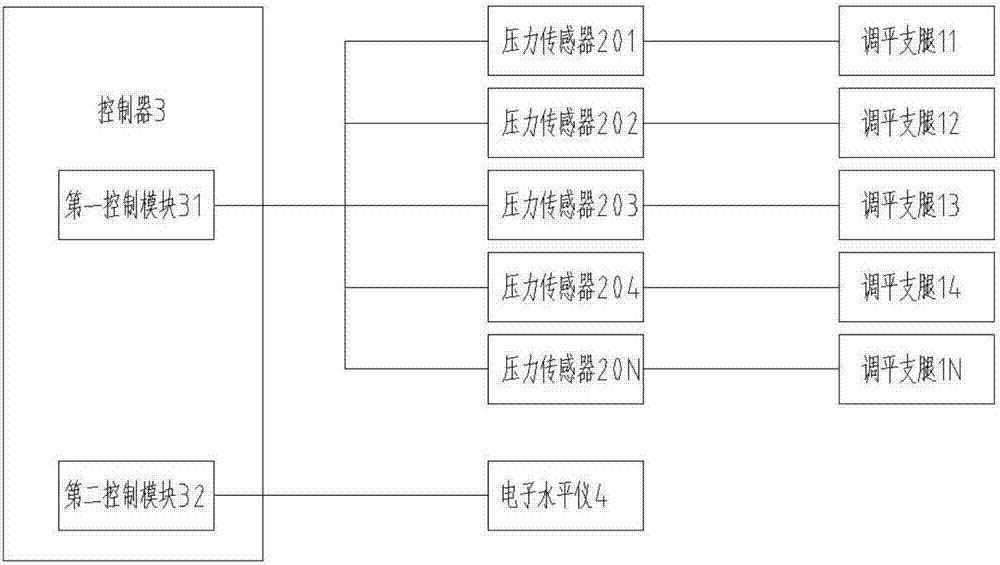

Examples

Embodiment 2

[0058] Compared with the pressure sensor in Embodiment 1, the position sensor in Embodiment 2 has the advantages of simple structure, high reliability, good environmental adaptability, and low price, but its sensitivity is not as good as that of the pressure sensor, which may cause deviation of the predetermined extension length L Big. Different leveling equipment can choose appropriate sensors according to their own needs to realize the identification and leveling of virtual legs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com