Preparation method of microwave and hybrid circuit tube shells of aluminum silicon carbide materials

A technology of aluminum silicon carbide and hybrid circuits, which is applied in microwave heating, electrical equipment shells/cabinets/drawers, electrical components, etc., can solve the problems of low life, high thermal expansion coefficient, unstable use, etc., and achieve high thermal conductivity, Low coefficient of thermal expansion and high airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

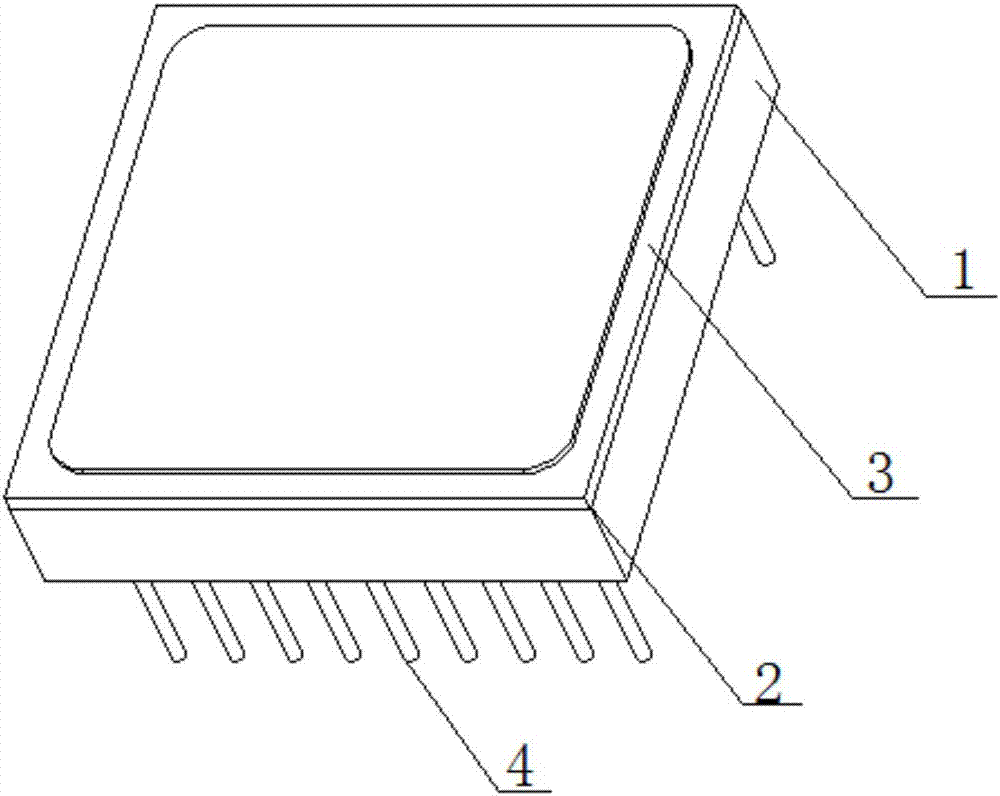

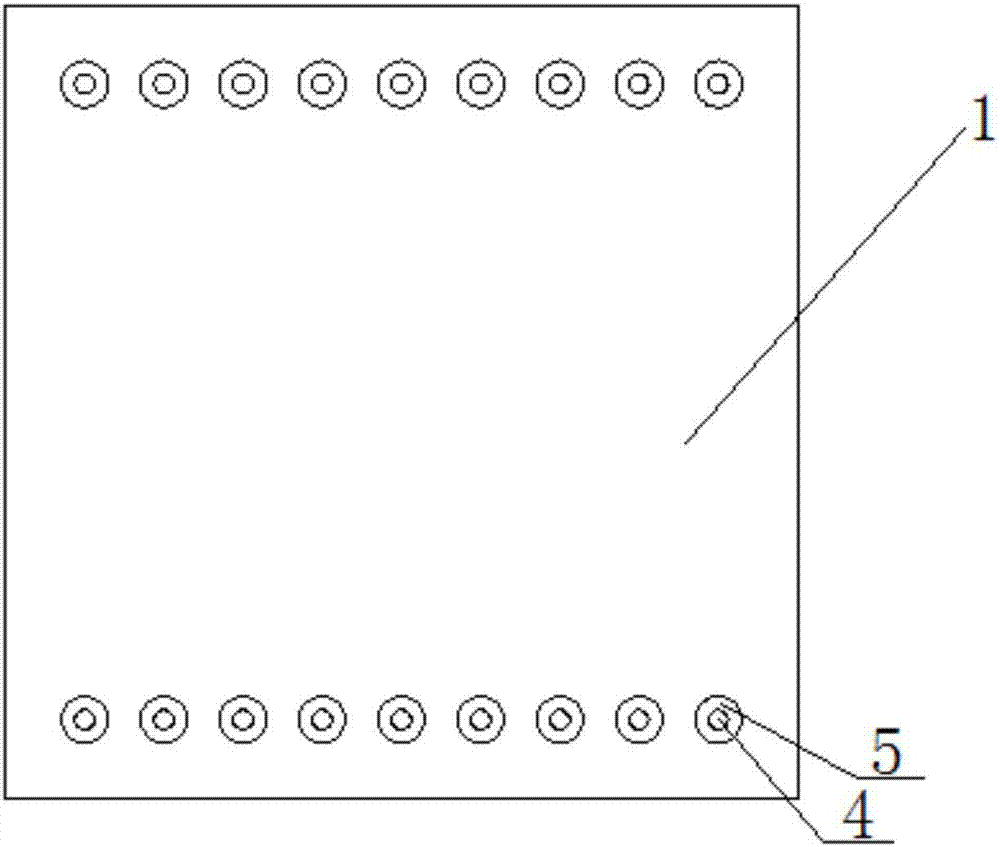

[0036] see figure 1 , the invention discloses a method for preparing a microwave and hybrid circuit shell made of aluminum silicon carbide, comprising the following steps:

[0037] S1. Cast aluminum silicon carbide shell 1, then machined and ground to the specified requirements;

[0038] S2. Use electric sparks to punch holes in the aluminum silicon carbide shell 1, and then seal the glass insulator 5 at the hole position. The sealing temperature is 450°C-550°C. The thermal expansion coefficient of the glass insulator 5 is 8-10. The inner lead wire is made of alloy Kovar lead wire 4;

[0039] S3. Using wire cutting and EDM to process the aluminum alloy cover plate 3, and then laser welding the aluminum silicon carbide shell 1 and the aluminum alloy cover plate 3, an aluminum layer is arranged before the aluminum silicon carbide shell 1 and the aluminum alloy cover plate 3 2;

[0040] S4. After sealing and welding, the surface of the shell is gold-plated.

[0041] Wherein, ...

Embodiment 1

[0062] Leave an aluminum layer with a thickness of 0.2 mm on the obtained aluminum silicon carbide tube shell, punch the tube shell and seal the glass insulator, laser seal and weld the aluminum alloy cover plate, the thickness of the aluminum alloy cover plate is selected to be 0.5 mm, nickel-plated 3 μm, gold-plated 2 μm, and the aluminum alloy is obtained. Silicon carbide microwave and hybrid circuit shell, its structure is as follows figure 1 and figure 2 shown.

Embodiment 2

[0064] Leave an aluminum layer with a thickness of 0.5mm on the obtained aluminum silicon carbide tube shell, punch the shell and seal the insulator, laser seal and weld the aluminum alloy cover plate, the thickness of the aluminum alloy cover plate is 1mm, nickel plating 2.5μm, gold plating 1.5μm, to obtain aluminum Silicon carbide microwave and hybrid circuit case.

[0065] Gained embodiment 1 and the shell that embodiment 2 obtains carry out insulator air tightness test result 10 -8 ~10 -9 Pam 3 / s, the airtightness test result of the sealing and welding of the tube shell is 10 -7 ~10 -8 Pam 3 / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| sealing temperature | aaaaa | aaaaa |

| sealing temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com