Movable friction type central guardrail and manufacturing method thereof

A guardrail and central technology, which is applied in the field of movable frictional central guardrail, can solve problems such as vehicle damage and personnel injury, and achieve high safety, reduce vehicle damage, and good anti-collision capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the examples, rather than limiting the protection scope of the claims of the present invention.

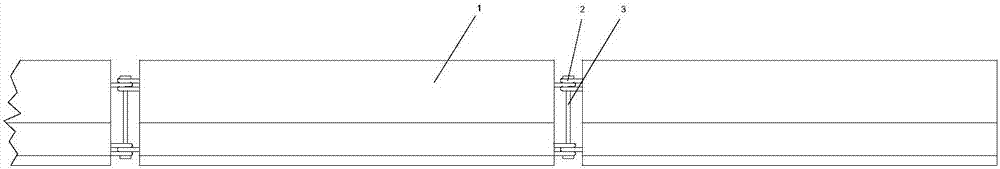

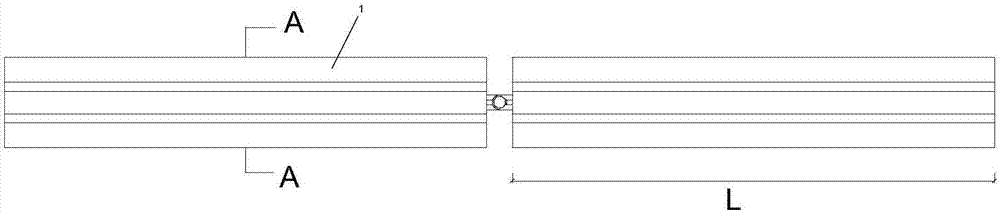

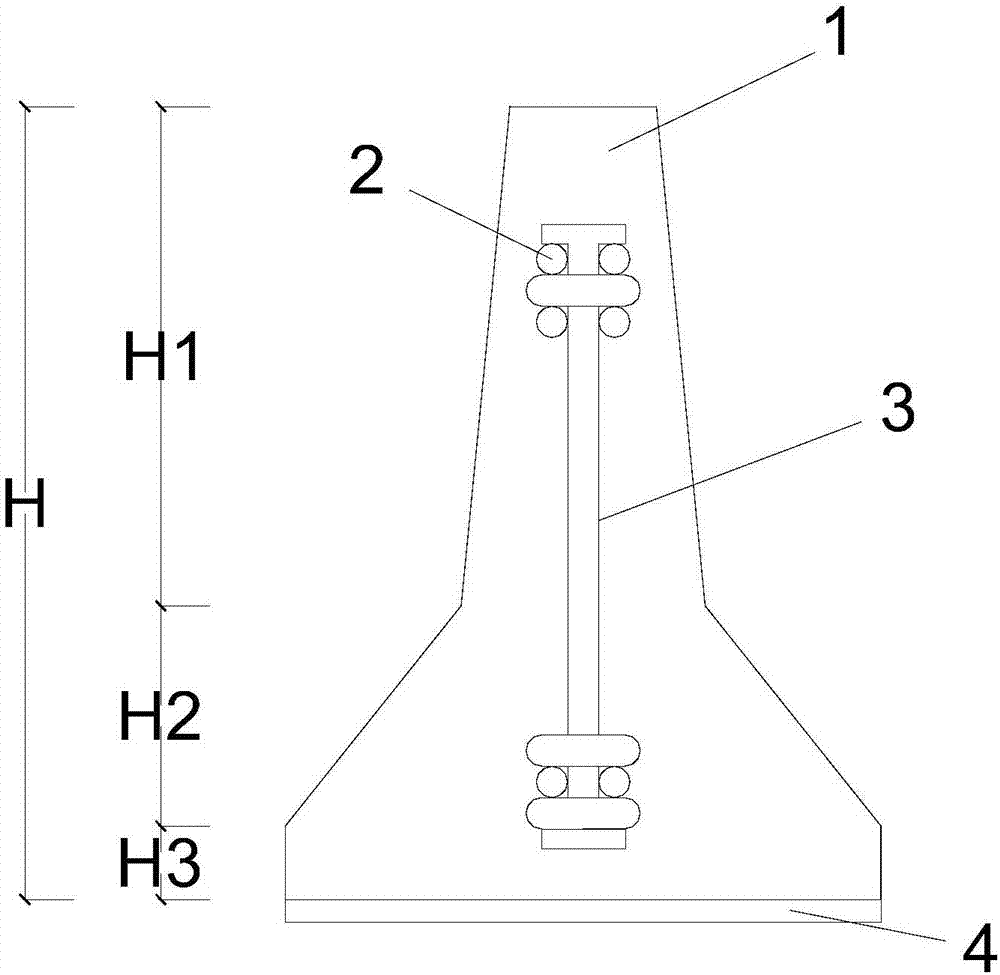

[0029] Such as Figures 1 to 8 As shown, a movable frictional central guardrail includes a guardrail segment 1 of a reinforced concrete structure, the concrete strength grade is C30, and the internal steel skeleton meets the structural reinforcement and force requirements. The guardrail segment 1 The bottom surface is slidingly connected to the road. The bottom surface of the guardrail segment 1 is provided with a friction surface 4 that improves friction with the road. Made of steel (Q345), the adjacent guardrail segments 1 can relatively slide and rotate around hinge points on the road. The connector includes a cotter pin 31 pre-embedded on the guardrail segment and a bolt 32 installed on the cotter pin 31. In this example, the bolt 32 adopts a long bolt, and the two cotter pins are arranged vertic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com