Densely-drilled sand-filled vibration-isolation pile row blasting-vibration-resisting structure

A blasting vibration and vibration isolation technology, which is applied in infrastructure engineering, protective devices, buildings, etc., can solve the problems of weakening the impact of vibration and shielding, and achieves easy implementation, low cost, and reduces the harmful effects of chamber excavation blasting vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

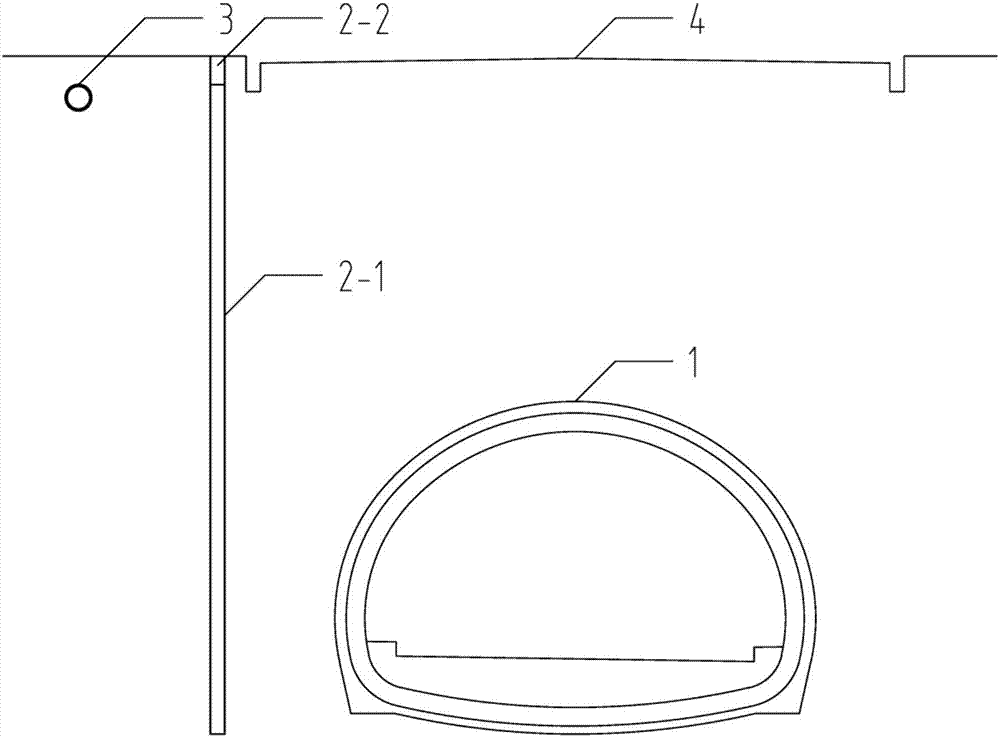

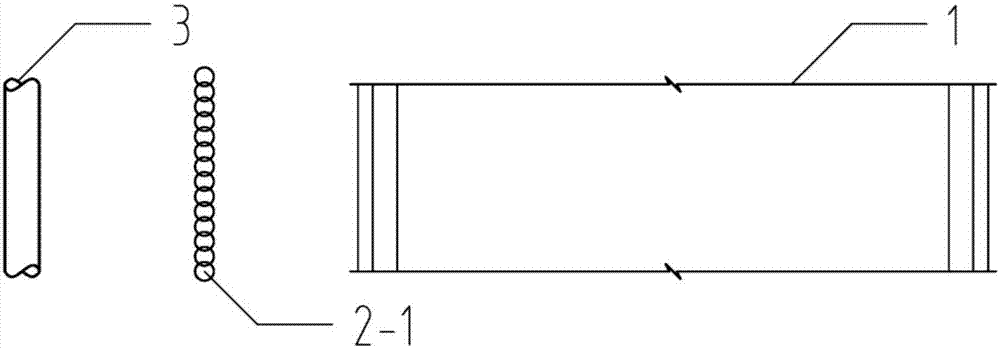

[0023] Structure and layout form of the present invention refer to figure 1 , 2 shown.

[0024] The present invention is a technical measure adopted in order to ensure the safety and normal use of adjacent underground pipelines or underground buildings (structures) in the construction of underground engineering such as road tunnels excavated by the drilling and blasting method, and to reach the blasting vibration velocity control standard.

[0025] In order to achieve the above purpose, the technical means, technical solutions, working principles, structural features, etc. adopted in the invention, (for the invention of products with no definite shape such as food, medicine, and materials, the composition ratio and processing technology of the product should be provided; for The method invention should provide the steps and conditions for implementing the method in detail) and describe it clearly and accurately. The invention points of these inventions that are different fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com