Method for conducting wall painting construction through mortar spraying

A mortar and powder wall technology, which is applied in the direction of construction and building construction, can solve the problems of poor bonding effect between mortar and wall surface, no nozzle control method, and large loss of mortar ejection, etc., so as to maintain physical properties and adhesion Strong, extended coating life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

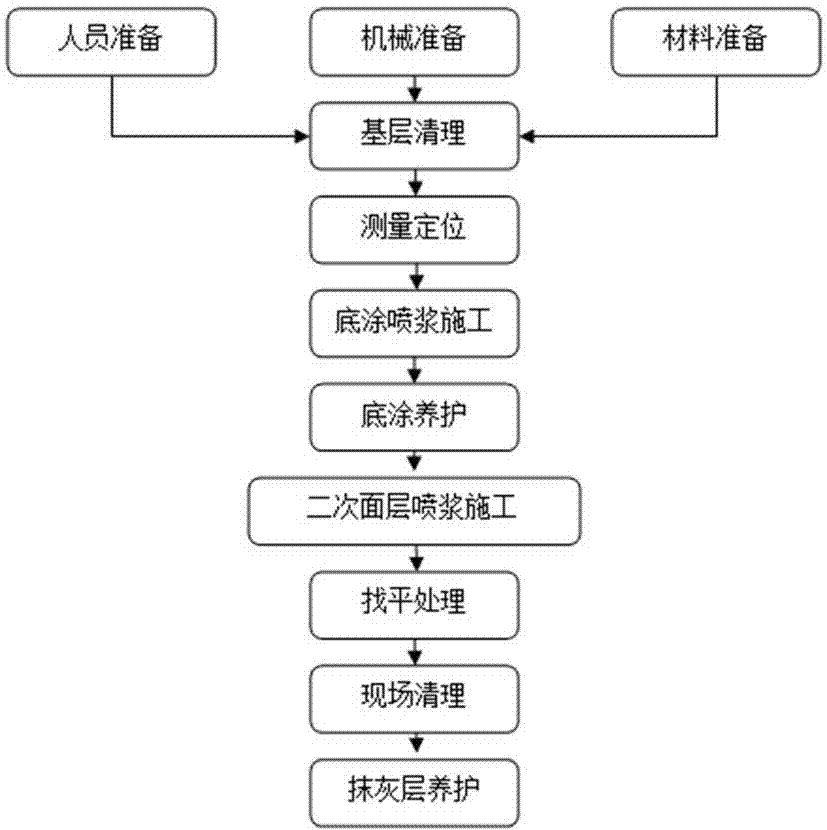

[0030] Embodiment one: see figure 1 Shown, a kind of method that adopts mortar spraying to carry out powder wall construction, comprises the following steps:

[0031] (1) Pre-treat the surface of the wall to be sprayed; specifically:

[0032] ① Use cement mortar or fine stone concrete to repair scaffold holes, including cantilevered I-beams and scaffold holes.

[0033] ②The surface of the concrete wall needs to use a wire brush to remove laitance, release agent, oil stains and formwork residues, and cut off the exposed steel head and chiseled protruding concrete blocks; clean the dust on the masonry wall and remove the laitance on the wall , Protruding mortar blocks.

[0034] ③ When the concrete surface exceeds the plastered finish surface, the excess part should be chiseled off.

[0035] ④ When it is necessary to wet the wall surface, use a sprayer to spray water to wet the surface of the masonry, so that the base layer can absorb water evenly. The moisture content of con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com