Method for monitoring NOx sensors

A sensor, SCR catalyst technology, applied in electrical control, engine control, machine/engine, etc., can solve problems such as difficult monitoring and small emission measurement signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

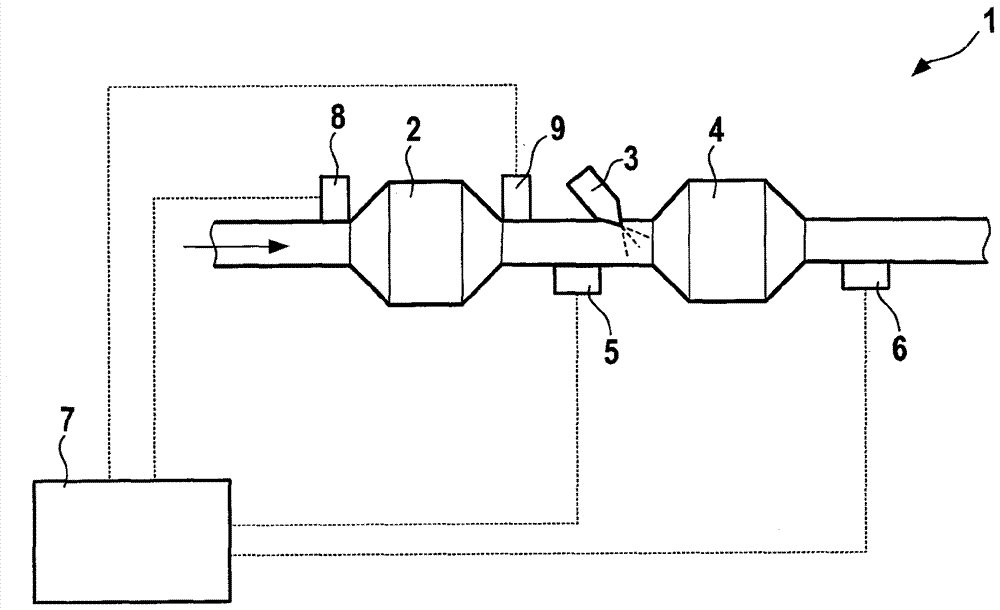

[0022] figure 1 A first exhaust gas aftertreatment system 1 (not shown) of a motor vehicle is schematically shown, in which a NOx sensor is monitored by means of a method according to an exemplary embodiment of the invention. The exhaust gas aftertreatment system 1 has an NSC / cDPF catalytic converter (NOx storage catalytic converter (NOx storage catalytic converter) and a coated diesel particulate filter) 2 , a reducing agent dosing point 3 , an SCR catalytic converter 4 , in the SCR The first NOx sensor 5 upstream of the SCR catalytic converter 4, the second NOx sensor 6 downstream of the SCR catalytic converter 4, the first temperature sensor 8 upstream of the NSC / cDPF catalytic converter 2, the The second temperature sensor 9 downstream of the NSC / cDPF catalytic converter 2 and the electronic controller 7 are connected. The controller 7 has data connections to the NOx sensors 5 , 6 and to the temperature sensors 8 , 9 .

[0023] figure 2 A second exhaust-gas aftertreatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com