Fire cover for burner

A burner and fire cover technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of difficult cleaning, secondary air replenishment, low thermal efficiency, etc., achieve uniform annular heating, reduce separation, The effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The features of the present invention and other relevant features will be described in further detail below through embodiments in conjunction with the accompanying drawings, so as to facilitate the understanding of those skilled in the art.

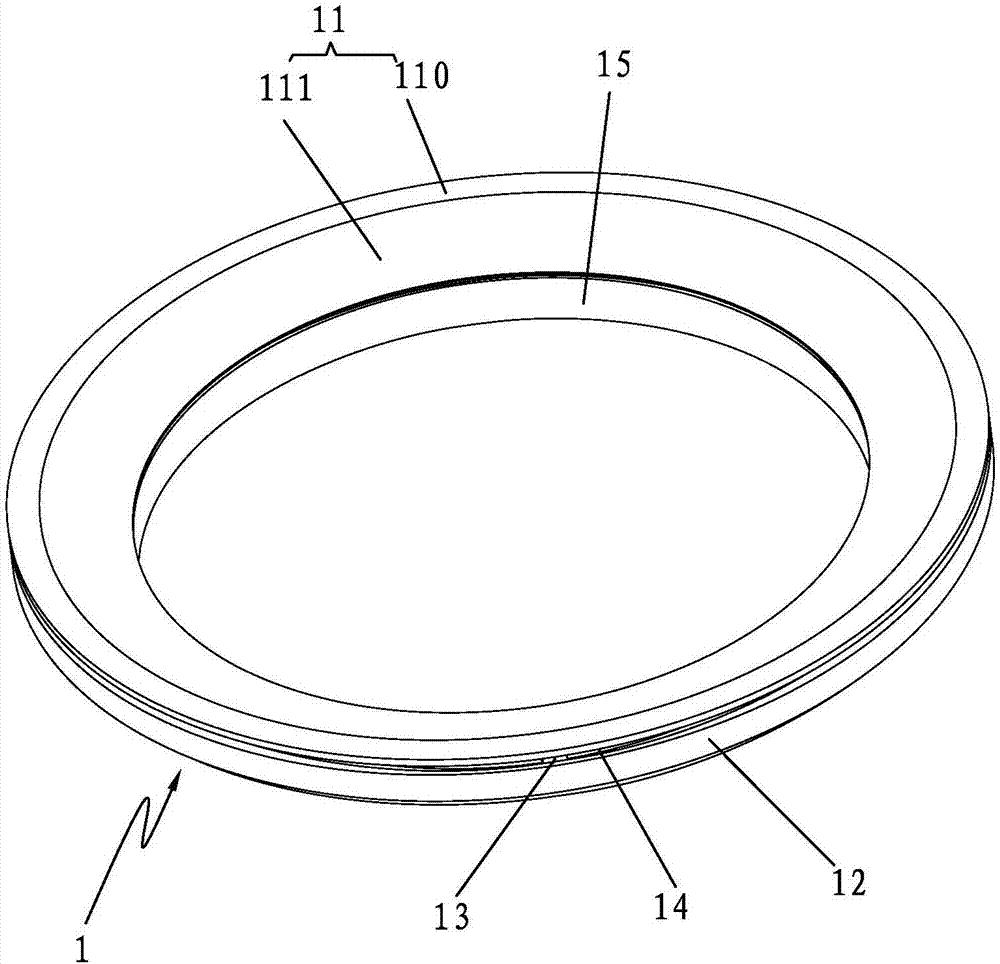

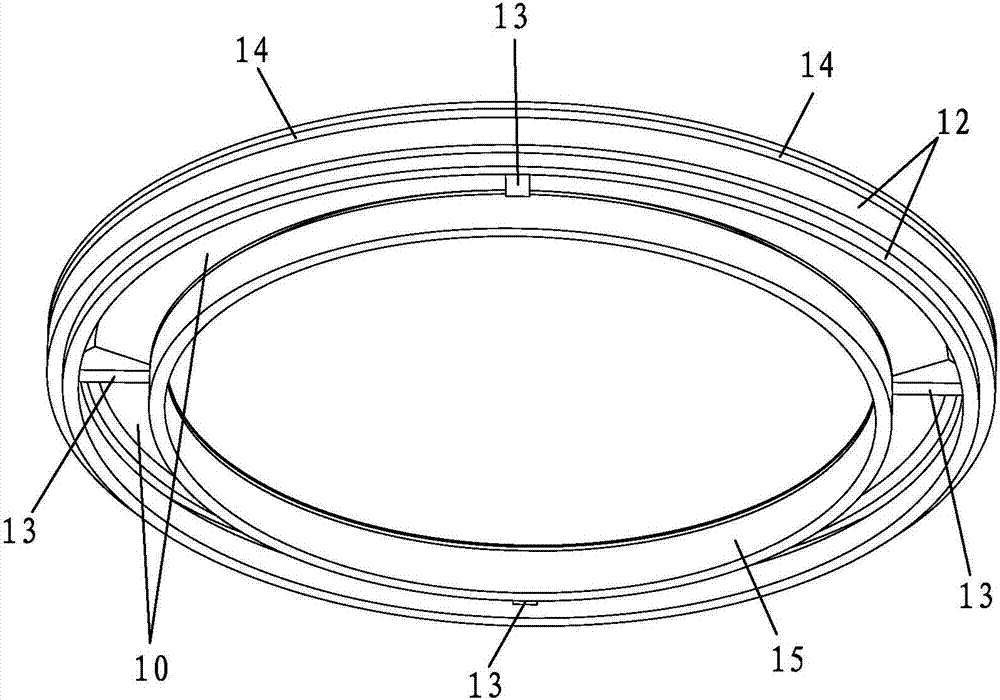

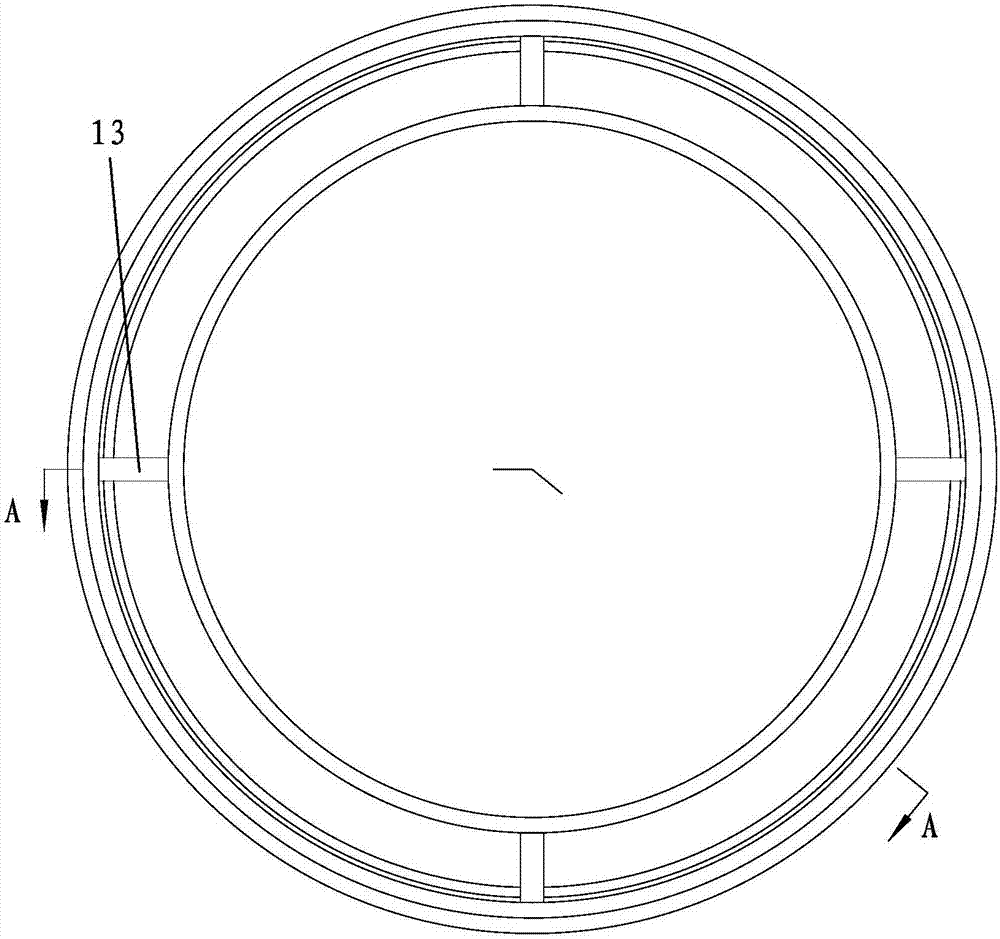

[0034] like Figure 1 to Figure 4 As shown, a fire cover for a burner includes an outer ring fire cover body 1, an annular outer wall body 12, an annular upper wall body 11, and an annular inner wall body 15 of the outer ring fire cover body 1 Surrounded by an annular gas chamber 10 opening downwards, the annular upper wall body 11 and the annular outer side wall body 12 are connected by a number of connecting ribs 13 and there is formed between the two to communicate with the annular gas chamber 10 Several slit-type outward fire hole passages 14, the slit-type outward fire hole passages 14 are arranged obliquely upward from the annular gas chamber 10 to the outer wall of the outer ring fire cover body 1, and the slit-type outward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com