Aluminum material spiral pushing preheater

A technology of spiral push and preheating machine, which is applied in the direction of preheating cost, furnace material, lighting and heating equipment, etc., which can solve the problems of increasing heat supply, absorbing more heat, and large temperature difference, so as to reduce the cost of enterprises , Improve the utilization rate and reduce the pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

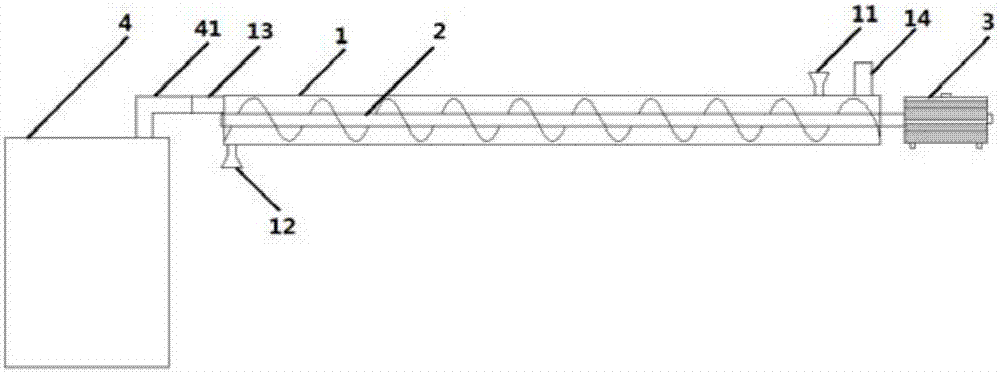

[0013] A kind of aluminum material spiral pushing preheating machine, such as figure 1 As shown, it includes a conveying pipe, a screw propulsion shaft that penetrates in the conveying pipe and is coaxially arranged with it, and a motor that drives the screw propulsion shaft to rotate. The two ends of the conveying pipe are respectively provided with an inlet and an outlet. An air inlet pipe and an air outlet pipe are also provided on the conveying pipe, and the air inlet pipe is connected with the exhaust pipe of the aluminum material melting furnace. At least one of the air pipe and the air outlet pipe is located between the feed inlet and the feed outlet.

[0014] Further, the conveying pipe is fixed horizontally, the feeding port is located at the upper part of one end of the conveying pipe, the discharge port is located at the lower part of the other end of the conveying pipe, the motor is fixed at one end of the feeding port of the conveying pipe, the output shaft of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com