Hydrodynamic device capable of precisely controlling pressure and boosting method

A technology of fluid power and precise control, which is applied in the direction of fluid pressure actuators, fluid pressure converters, servo motors, etc., and can solve the problem of inability to meet the requirements of precise pressurization and precise depressurization, air compressors with large vibration and noise, and one-way Problems such as large single minimum passage of the valve achieve the effect of small vibration, reduced noise and vibration, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

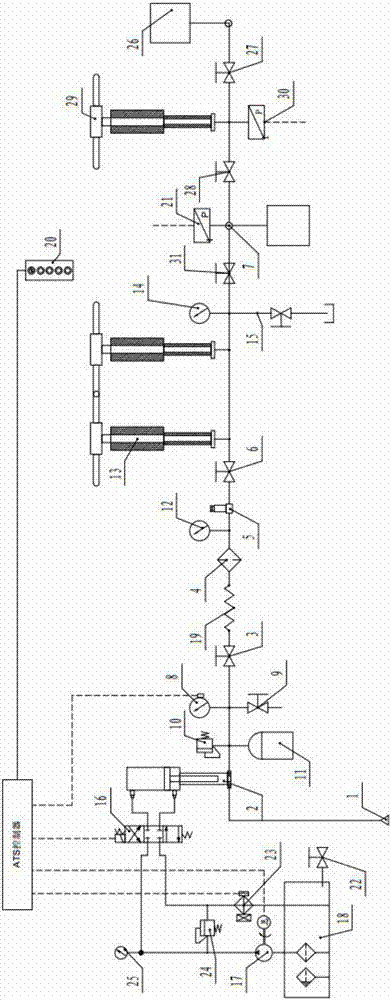

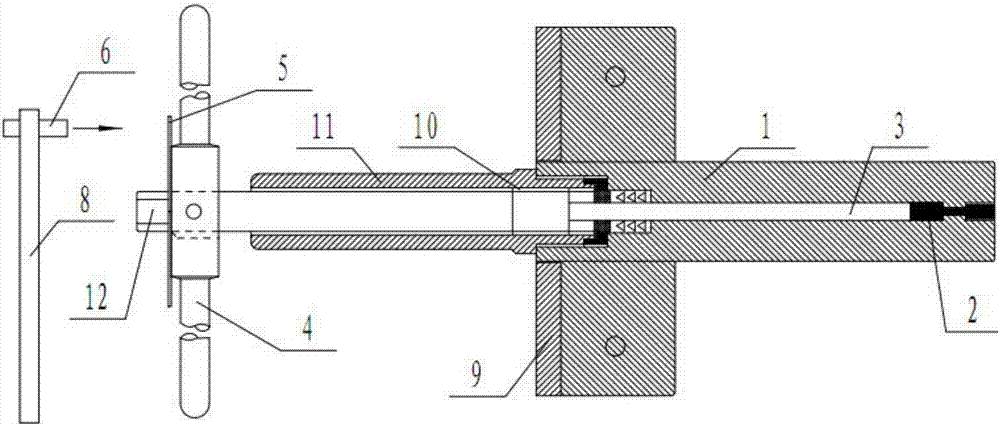

[0039] Embodiment 1: as Figure 1-Figure 2 As shown, a fluid power device that can precisely control the pressure includes a gas booster pipeline system and a liquid booster pipeline system connected in parallel to the pressure port 7. The gas booster pipeline system includes gas cylinders 1, Booster pump 2, medium pressure shut-off valve 3, filter 4, pressure reducing valve 5, high pressure shut-off valve 3 6 and high pressure shut-off valve 4 31. The pressure valve 9 and the high-pressure gas storage tank 11, the pipeline between the high-pressure shut-off valve 3 6 and the high-pressure shut-off valve 4 31 are connected with a gas high-pressure booster cylinder 13 and a high-pressure pressure relief valve 15, and the liquid booster pipeline system includes regular connections connected in sequence. Pressurized liquid container 26, liquid high-pressure shut-off valve one 27 and liquid high-pressure shut-off valve two 28, liquid booster cylinder 29 is connected on the pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com