Mini-sized three-dimensional topography measurement system and mini-sized three-dimensional topography measurement method based on LED microscopic fringe projection

A fringe projection, three-dimensional topography technology, applied in the field of optical measurement, can solve the problems of complex method, difficult optical path adjustment, and reduced fringe contrast, and achieves the effects of low price, simple optical path adjustment, and suppression of the influence of coherent noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention will be further described below in conjunction with specific embodiments.

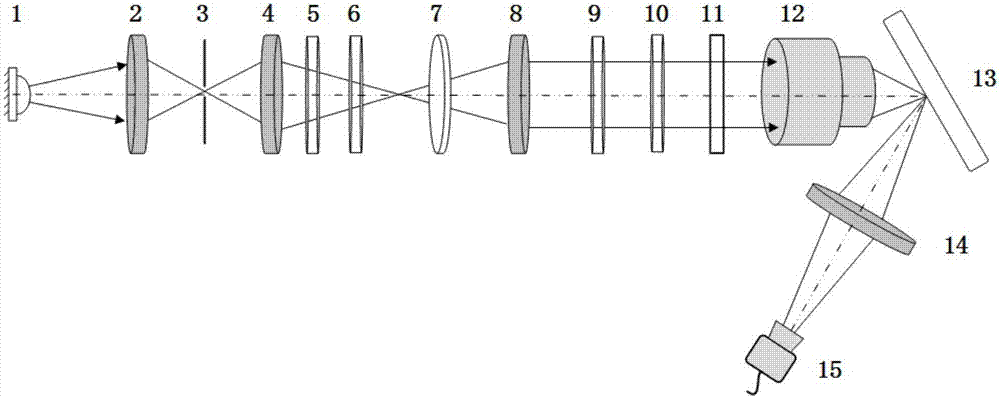

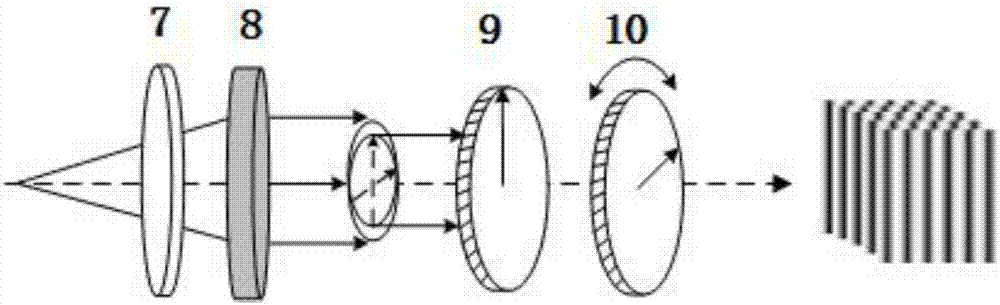

[0037] The light path of the implementation of the method for measuring the small three-dimensional shape based on low-coherence LED micro fringe projection of the present invention includes four parts: LED shear light path, phase shift interference light path, micro fringe projection light path, and image data collection light path. As attached figure 1 As shown, the microscopic three-dimensional topography measurement system based on low-coherence LED micro fringe projection of the present invention includes an LED light source 1, a lens 2, a pinhole filter 3, a lens 4, a polarizer 5, and a hard film interference filter 6. , Birefringent uniaxial crystal 7, collimating lens 8, 1 / 4 wave plate 9, analyzer 10, adjustable diaphragm 11, microscope objective lens 12, tested sample 13, double cemented lens 14, industrial camera 15.

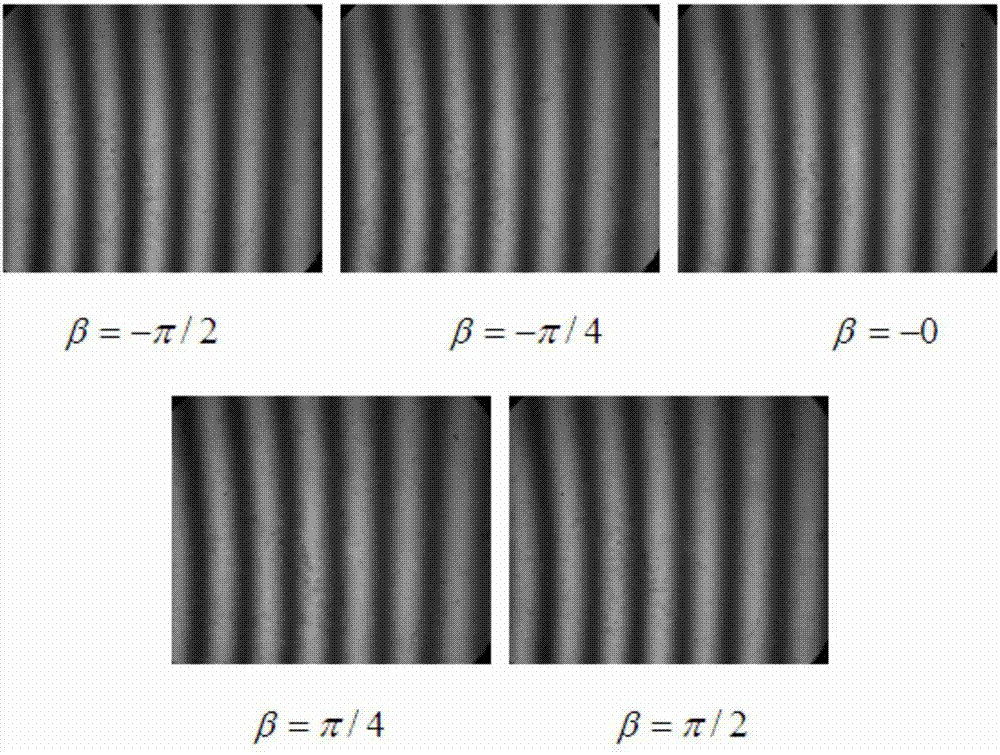

[0038] System working pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com