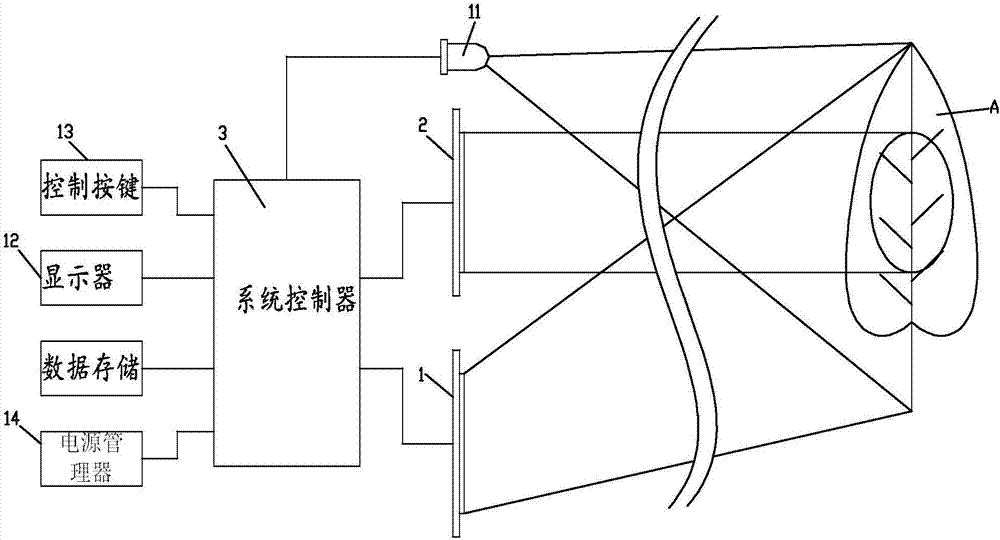

Photographing type intelligent spectral analysis system

A spectrum analysis and spectrum separation technology, applied in the field of photographic intelligent spectrum analysis systems, can solve the problems of difficult alignment of detected substances, insufficient parallelism of parallel light, poor directivity, etc., and achieves improved integration and convenience for portability and use. performance, strong practical value and market promotion value, and the effect of improving sensitivity and detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

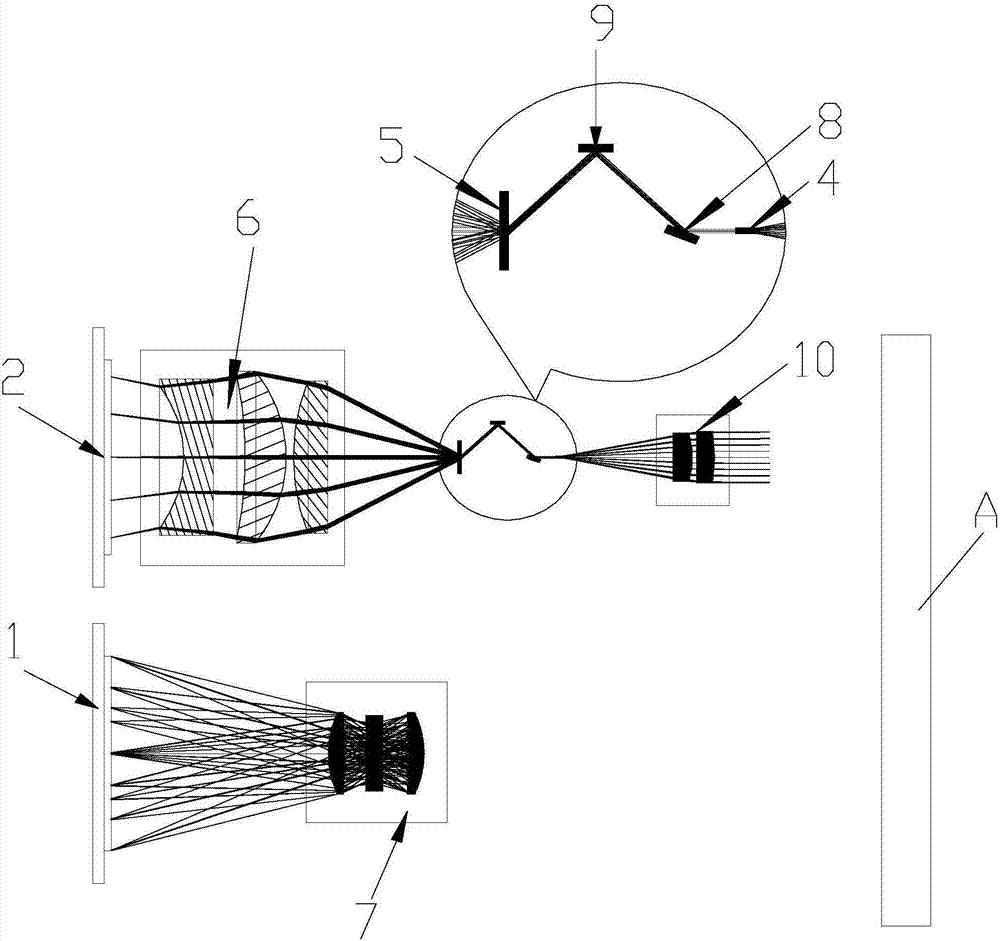

Embodiment 1

[0025] Embodiment one, such as figure 2 As shown, the imaging and light compression lens group is an imaging lens group 7, the imaging lens group 7 images the object A through the light reflected by the object A, and then projects the imaging light onto the image sensor 1 and simultaneously compresses part of the imaging light into a polychromatic light beam, the collimating lens group 4 is placed on the light-emitting side of the imaging lens group 7 and coaxially distributed with the imaging lens group 7 to collimate the polychromatic light beam into a polychromatic parallel light beam; and the total reflection mirror group includes the front The first stage total reflection mirror 8 and the rear stage total reflection mirror 9, the front stage total reflection mirror 8 is placed between the collimating lens group 4 and the image sensor 2 to form the polychromatic parallel beams formed after collimating through the collimating lens group 4 90° optical path steering, the rea...

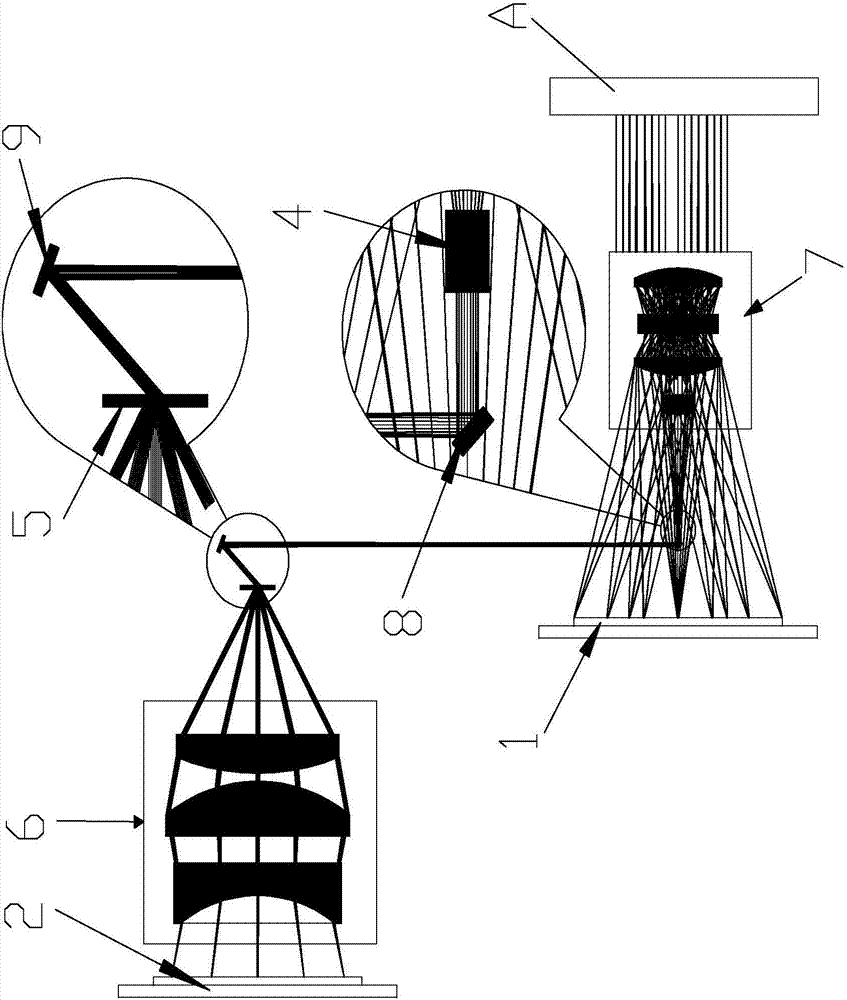

Embodiment 2

[0026] Embodiment two, such as image 3 As shown, the imaging and light compression lens group includes an imaging lens group 7 placed on the photosensitive surface side of the image sensor 1 and a light compression lens group 10 placed on the photosensitive surface side of the spectrum sensor 2 and distributed in parallel with the imaging lens group 7 (It is shared with imaging lens group 7), and imaging lens group 7 projects imaging light onto the image sensor 2 after imaging object A through the light reflected by object A, while light compression lens group 10 then reflects object A The light is compressed to form a polychromatic beam, and the collimating lens group 4 is placed on the light-emitting side of the light compression lens group 10 and distributed coaxially with the light compression lens group 10 to collimate the polychromatic beam into a polychromatic parallel beam; total reflection The mirror group includes a front-stage total reflection mirror 8 and a rear-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com