Synchronous multi-analyte sensing test paper for isolating current interference by sample feeding gaps and application of synchronous multi-analyte sensing test paper

An analyte and injection port technology, applied in the field of simultaneous multi-analyte sensing test paper, can solve the problems of impossibility of accuracy and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The preparation method of the above-mentioned synchronous multi-analyte sensing test paper that isolates the current interference from the sampling gap comprises the following steps:

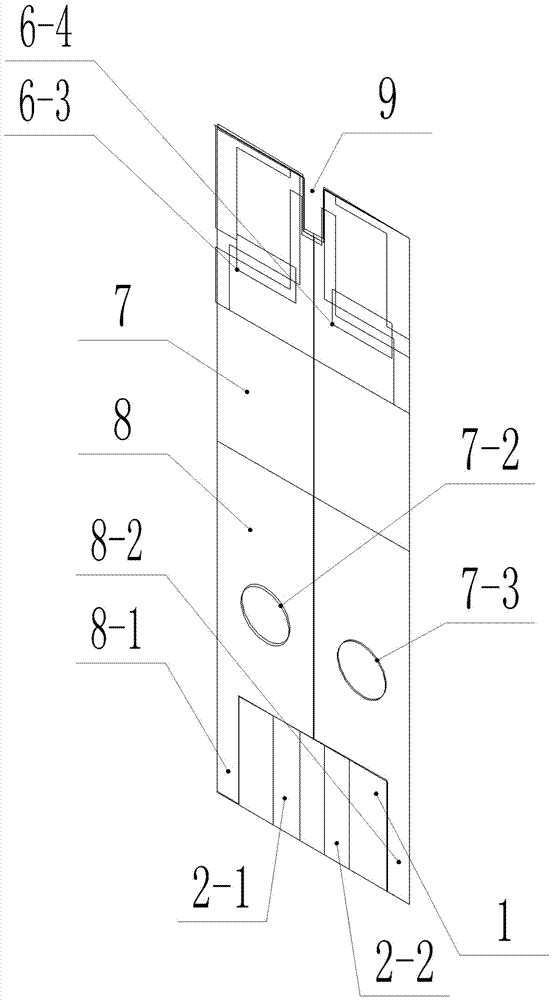

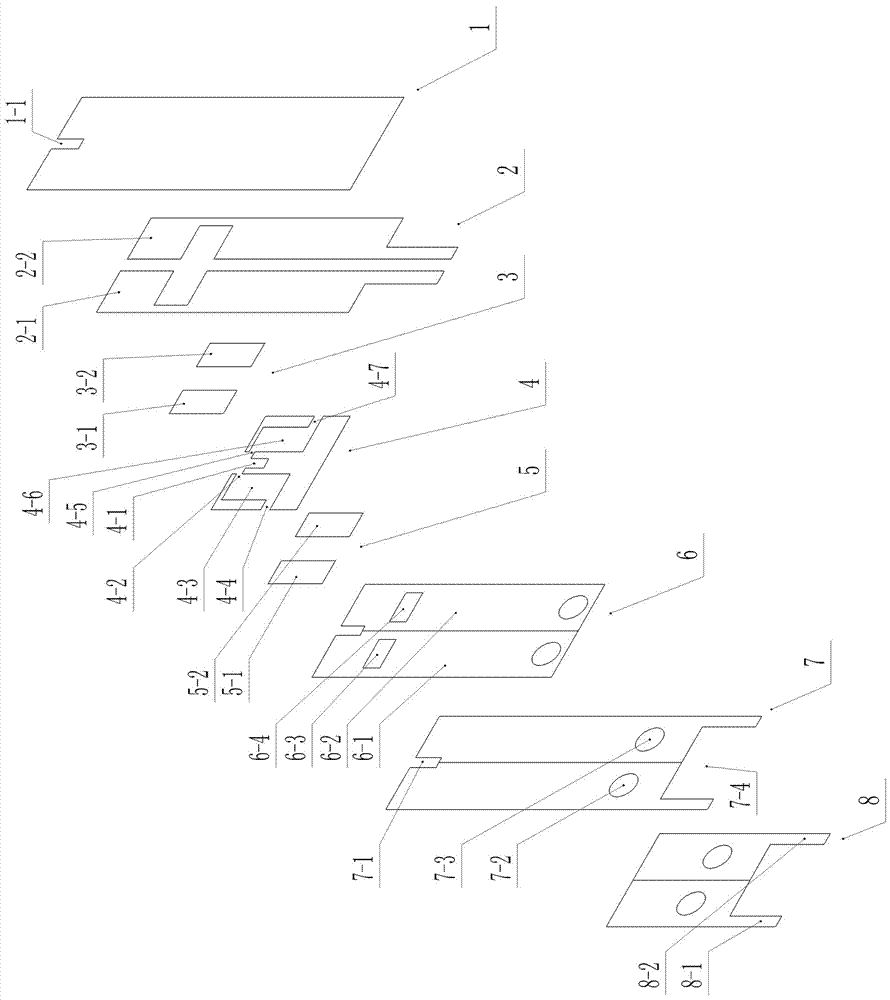

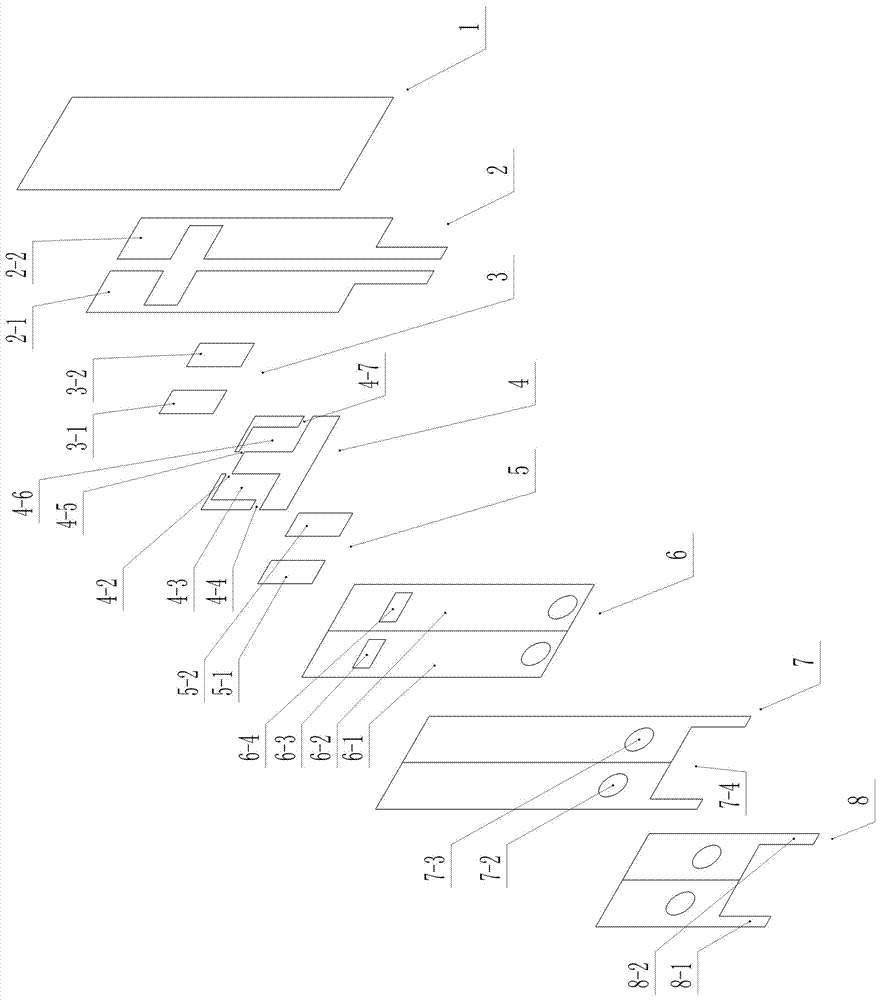

[0067] 1) Process a first sampling notch 1-1 on the first insulating substrate 1; process a second sampling notch 7-1, a first via hole 7-2, a second sampling notch 7 on the second insulating substrate 7 Two via holes 7-3 and a substrate gap 7-4;

[0068] 2) Print the first conductive film layer 2 on the first insulating substrate 1, put it in an oven at 70-90°C and dry it for 50-70min to form the first reactant working electrode 2-1 and the second reactant working electrode 2 -2;

[0069] 3) Spray the first reaction film 3-1 on the first reactant working electrode 2-1, then spray the second reaction film 3-2 on the second reactant working electrode 2-2, and then 40-60°C Dry for 10-30min and set aside;

[0070] 4) Paste the liquid guide tank body 4 with the third sampling notch 4-1 on ...

Embodiment 1

[0080] This example provides a preparation example of a multi-analyte sensing test paper for detecting glucose and total cholesterol in blood, thereby illustrating the method for preparing a synchronous multi-analyte sensing test paper that isolates current interference through the sampling gap of the present invention. The preparation method Including the following steps:

[0081] 1) Process a first sampling notch 1-1 on the first insulating substrate 1; process a second sampling notch 7-1, a first via hole 7-2, a second sampling notch 7 on the second insulating substrate 7 Two via holes 7-3 and a substrate gap 7-4;

[0082] 2) Print the first conductive film layer 2 on the first insulating substrate 1, put it in an oven at 80° C. and dry it for 60 minutes to form the first reactant working electrode 2-1 and the second reactant working electrode 2-2;

[0083] 3) Spray the first reaction membrane 3-1 enzyme solution that reacts with glucose in the blood, that is, the blood gl...

Embodiment 2

[0100] In this embodiment, the simultaneous multi-analyte sensing test paper prepared in Example 1 and the simultaneous multi-analyte sensing test paper prepared in Example 1 with a sample injection gap to isolate current interference and the simultaneous multi-analyte sensing test paper in Comparative Example 1 were used to test blood samples.

[0101]Collect fresh venous blood, adjust the hematocrit ratio to 40%, prepare two blood samples, test the blood sugar concentration with a YSI2300 glucose analyzer, and test the total cholesterol with a biochemical analyzer and a Fosun Long March total cholesterol biochemical kit. Test the synchronous multi-analyte sensing test paper with the sample injection gap to isolate current interference prepared in Example 1, place it in a supporting multi-parameter analyzer and apply a 300mV working voltage at both ends of the working electrode and the reference electrode; take the prepared blood sample, When it is added to the sampling gap, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com