Method for forming electrode patterns and electrode patterns

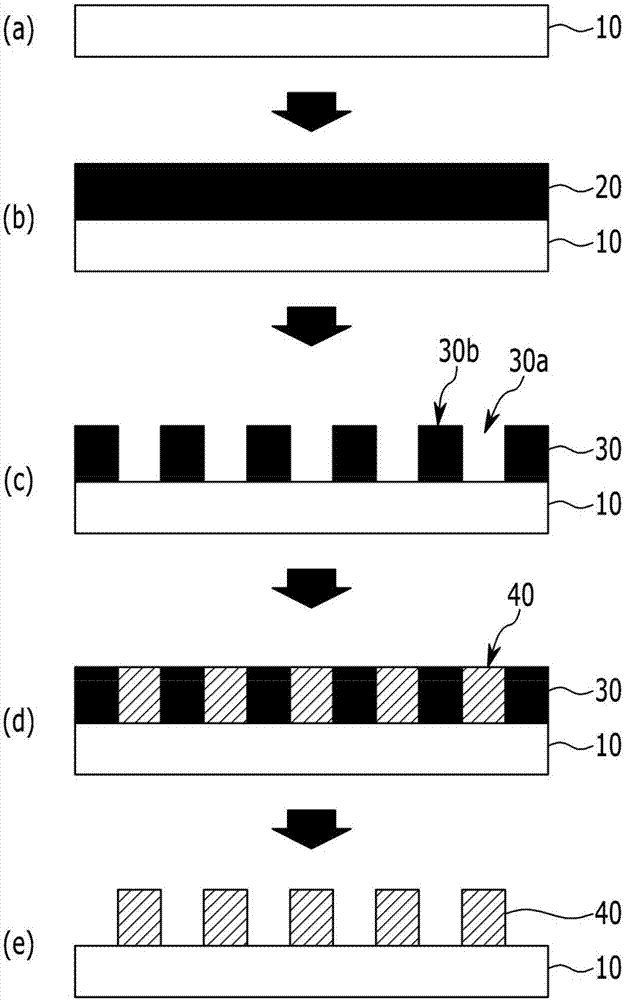

An electrode pattern and electrode technology, applied in the field of electrode patterns, can solve the problems of complex process and difficult formation of process characteristics, and achieve the effects of high design freedom, excellent position accuracy and quality improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

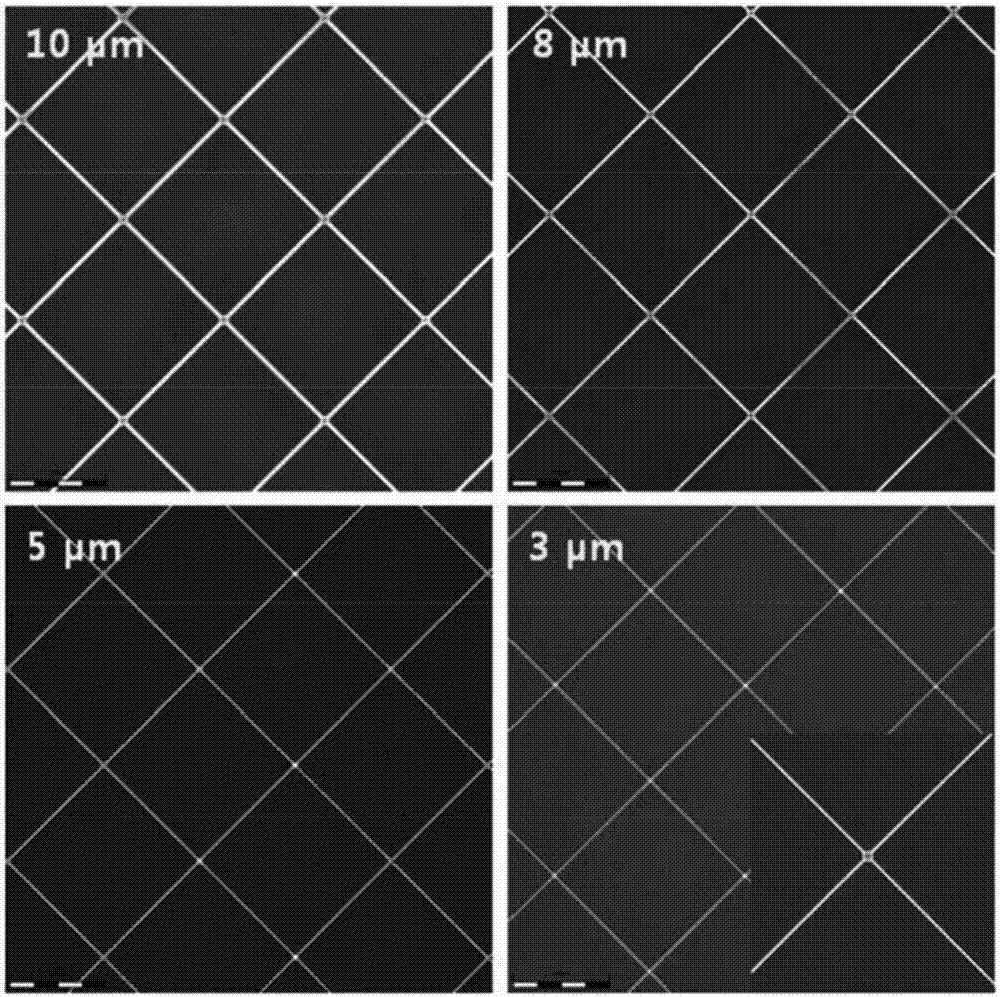

[0104] A soda-lime glass substrate generally used in the technical field to which the present invention pertains was prepared as a base for forming an electrode pattern.

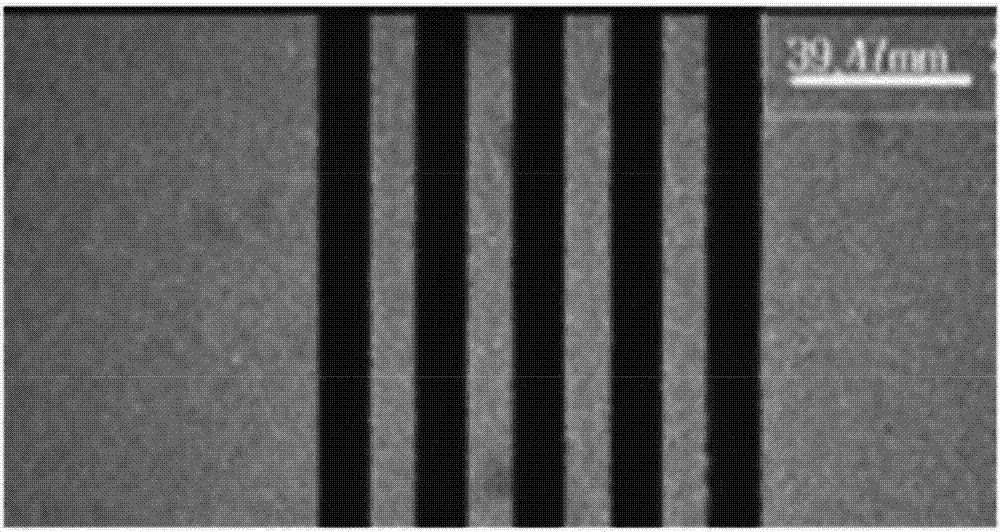

[0105] The photoresist composition (DTFR-JC800, positive type, manufacturer: Dongjin Smicon) was coated on the substrate with a thickness of 6 μm by spin coating, and then the hot plate was used at 90 °C for 120 seconds. The thickness measured after prebaking was 3 μm.

[0106] Then, the region coated with the photoresist composition was exposed to light with a wavelength of 365 nm by a proximity exposure machine (manufacturer: SEIWA) using a mask pattern for forming a line The mask pattern is a pattern with a width of 10 μm, and the cumulative exposure dose is 40 mJ.

[0107] Immerse the coated photoresist composition partially cured substrate in a developer solution (product name: DPD-200, alkaline developer solution, manufacturer: Dongjin Smicon) at 25°C for 60 seconds Development is performed to form ...

Embodiment 2

[0112] An electrode pattern was formed by the same method as in Example 1 except that the line width was 8 μm.

Embodiment 3

[0114] An electrode pattern was formed by the same method as in Example 1 except that the line width was 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com