A method for improving the recovery rate of heavy medium in coal preparation process

A technology of heavy medium and recovery rate, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problem of low recovery rate of heavy medium, and achieve the effect of saving resources, reducing consumption and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

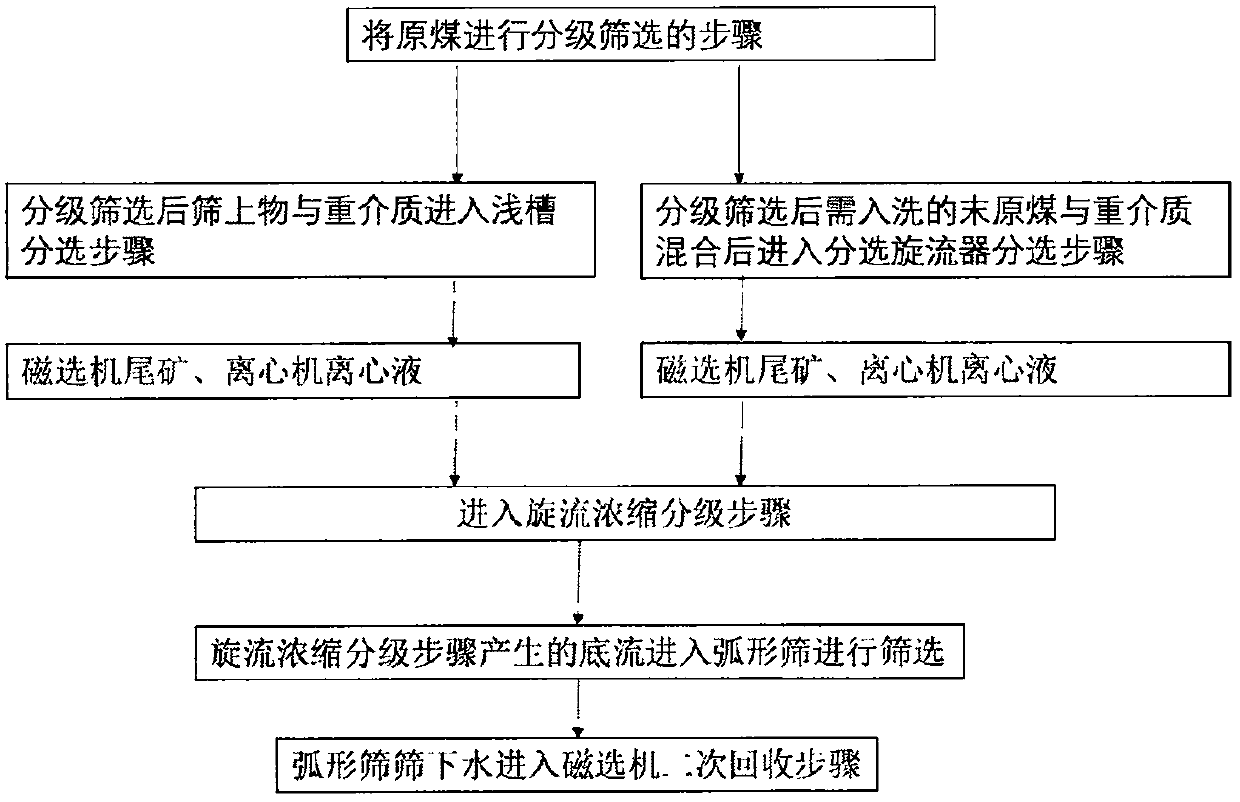

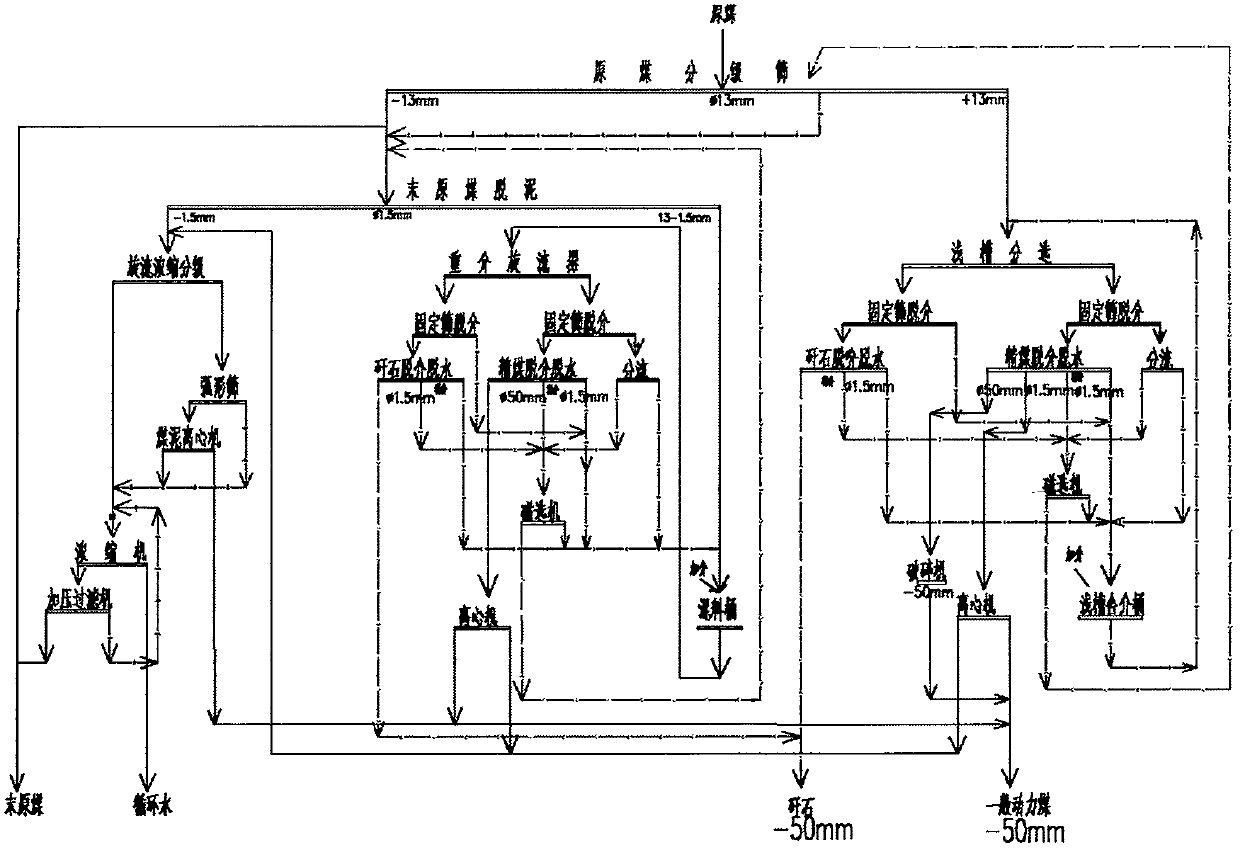

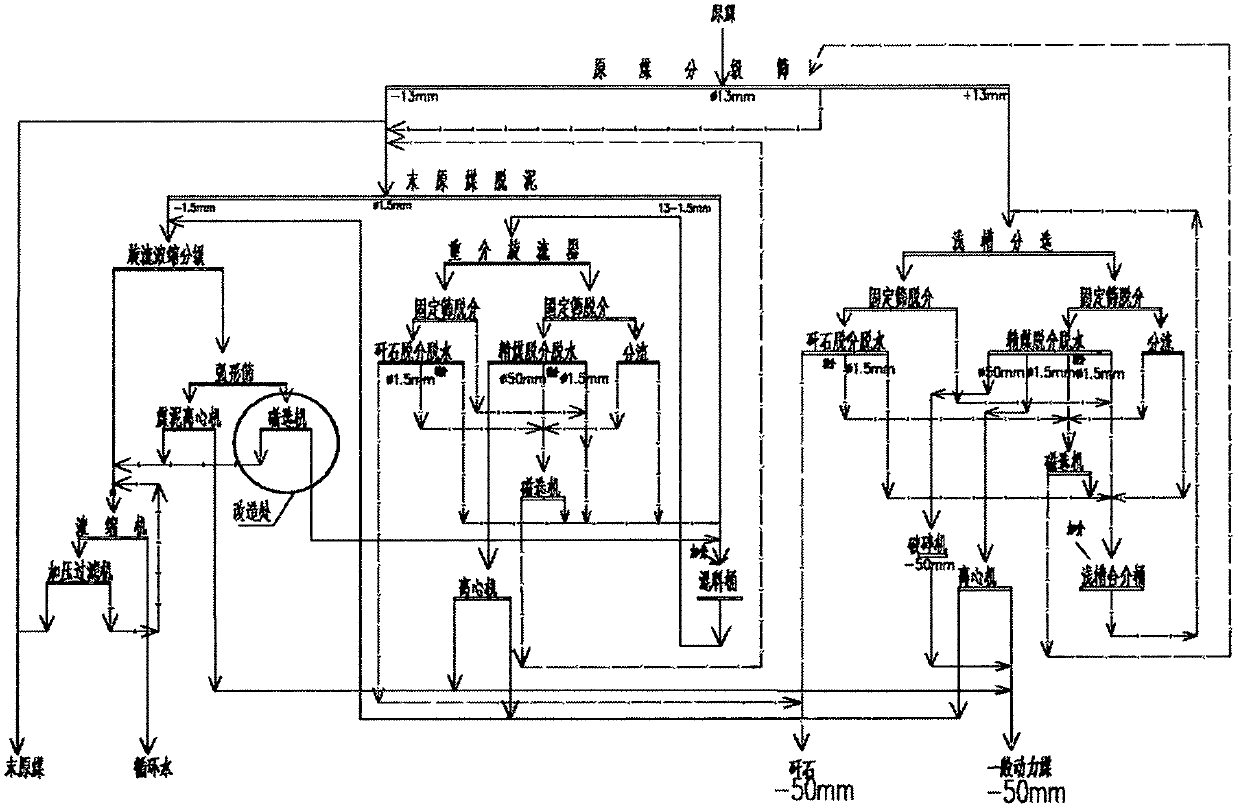

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical solution of the present invention easier to understand, the technical solution of the present invention will be described clearly and completely by means of specific embodiments in conjunction with the accompanying drawings. It should be noted that the embodiments described here are only some of the embodiments of the present invention, rather than all implementations of the present invention. The embodiments are only illustrative, and their role is only to provide examiners and the public with an understanding of the content of the present invention. A more intuitive and clear manner, rather than a limitation to the technical solution of the present invention. On the premise of not departing from the concept of the present invention, all other implementations that can be thought of by those skilled in the art without creative work, and other simple replacements and various changes to the technical solutions of the present invention, all be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com