Workpiece loading device capable of improving processed surface quality by wire saw cutting

A technology for cutting processing and surface quality, applied in the field of cutting processing, can solve problems such as accelerated chip discharge, difficult chip discharge, non-parallel slice surfaces, etc., to avoid severe wear, eliminate non-parallel cutting lines, and promote the effect of alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

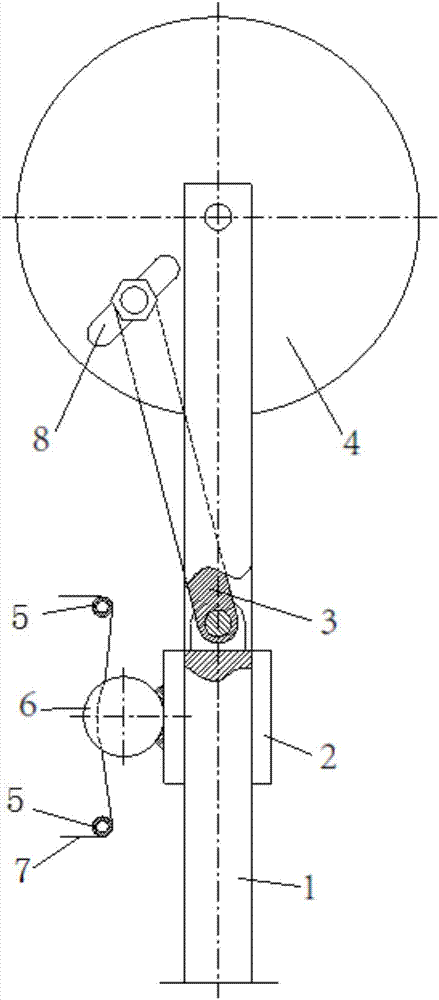

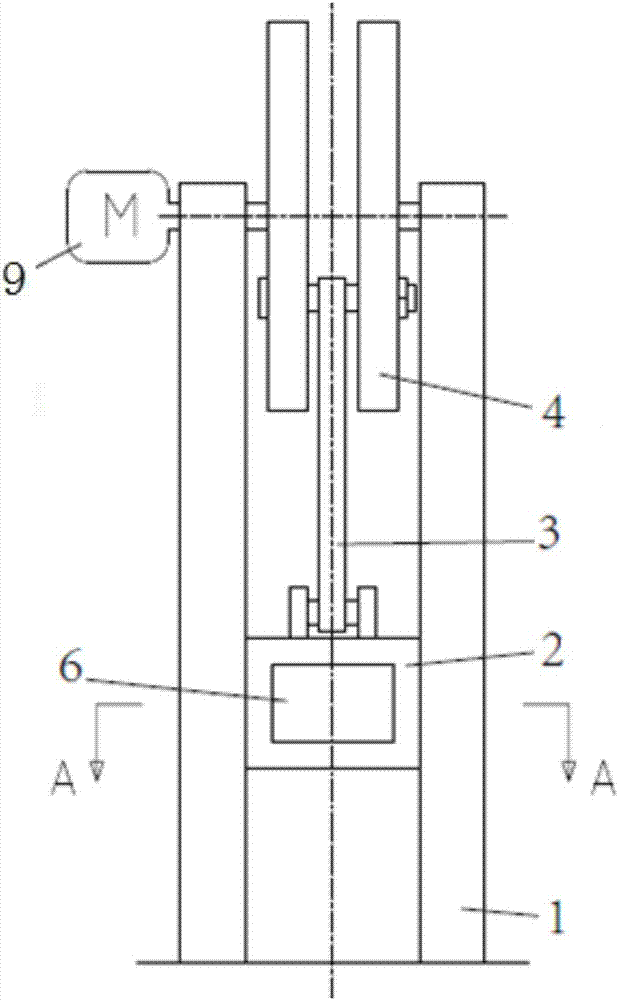

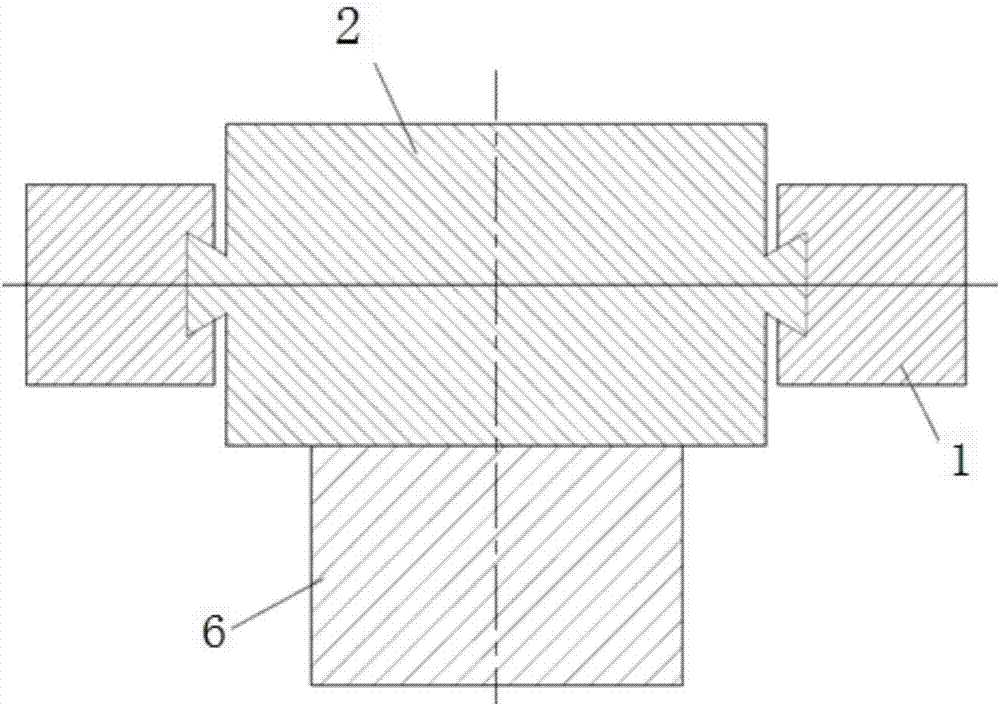

[0018] Such as figure 1 and figure 2 As shown, the workpiece loading device for improving the surface quality of wire saw cutting according to the present invention includes a workbench 1 and a material loading platform 2. The workbench 1 is provided with a guide rail in the vertical direction, and the material loading platform 2 is installed on the guide rail of the workbench 1. superior. The guide rail of workbench 1 is a dovetail slide rail, such as image 3 . A wheel disc 4 is installed on the workbench 1, and the wheel disc 4 is connected with a motor 9, and the motor 9 is also installed on the workbench 1, see figure 2 . The loading table 2 is connected with the wheel 4 through the connecting rod 3, and the wheel 4 is provided with a long hole 8, and one end of the connecting rod 3 is hinged with the loading table 2, and the other end of the connecting rod 3 is hinged with the wheel 4, and the hinge shaft Located in the elongated hole 8, the effective length of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap