Novel foaming PVC nose plug and making method thereof

A technology for PVC resin powder and nasal plug, which is applied in the field of new foamed PVC nasal plug, can solve the problems of skin redness, swelling or peeling, user injury, user discomfort, etc., and achieves the effect of reducing friction coefficient, low processing cost and easy molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

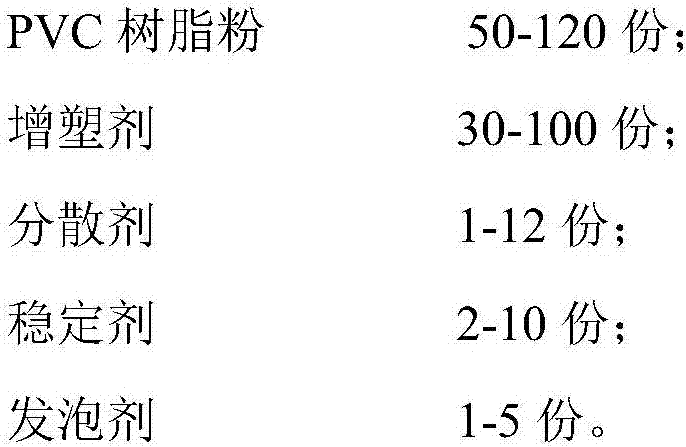

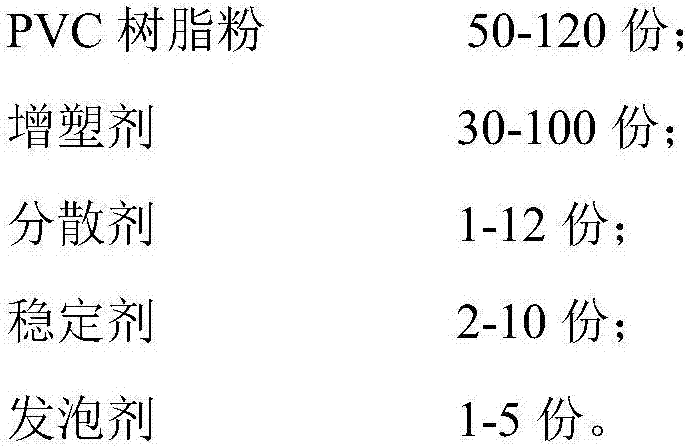

Method used

Image

Examples

Embodiment 1

[0019] The present embodiment makes foaming PVC nasal plug according to the following steps:

[0020] 1. Weigh 70 parts of PVC paste resin powder, 40 parts of dioctyl terephthalate, 10 parts of epoxy soybean oil, 2 parts of polycarboxylate sodium salt, 3 parts of calcium zinc stabilizer, microsphere foaming agent according to the formula 2 parts; mix the above raw materials evenly according to the formula to make PVC dipping solution.

[0021] 2. Heat the nasal plug mold to 150°C, then immerse the mold in PVC dipping solution, and take it out after 55s.

[0022] 3. Put the mold with PVC dipping liquid into the furnace at 400℃, and mold for 28s.

[0023] 4. Take out the plasticized and molded product, cool it in water to 50°C, and demold it to obtain a foamed PVC nasal plug.

[0024] After testing, the obtained product has a static friction coefficient of 0.23, a tensile strength of 7.7MPa, an elongation of 185% and a tear strength of 17.3MPa.

Embodiment 2

[0026] The present embodiment makes foaming PVC nasal plug according to the following steps:

[0027] 1. According to the formula, weigh 90 parts of PVC paste resin powder, 60 parts of trioctyl trimellitate, 15 parts of epoxy soybean oil, 3 parts of polycarboxylate sodium salt, 2 parts of calcium zinc stabilizer, lauryl sulfuric acid 4 parts of sodium; mix the above-mentioned raw materials according to the formula to make PVC dipping liquid.

[0028] 2. Heat the nasal plug mold to 170°C, then immerse the mold in the PVC dipping solution, and take it out after 35 seconds.

[0029] 3. Put the mold with PVC dipping liquid into the furnace at 420℃, and mold for 22s.

[0030] 4. Take out the plasticized and molded product, cool it in water to 50°C, and demold it to obtain a foamed PVC nasal plug.

[0031] After testing, the obtained product has a static friction coefficient of 0.25 for the skin on the back of the hand, a tensile strength of 4.7 MPa, an elongation of 135%, and a t...

Embodiment 3

[0033] The present embodiment makes foaming PVC nasal plug according to the following steps:

[0034] 1. Weigh 80 parts of PVC paste resin powder, 30 parts of dioctyl terephthalate, 35 parts of trioctyl trimellitate, 3 parts of hydroxy functional carboxylate, 4 parts of calcium stearate, microspheres according to the formula 2 parts of foaming powder; mix the above raw materials evenly according to the formula to make PVC dipping solution.

[0035] 2. Heat the nasal plug mold to 190°C, then immerse the mold in the PVC dipping solution, and take it out after 19s.

[0036] 3. Put the mold with PVC dipping liquid into the furnace at 440℃, and mold for 15s.

[0037] 4. Take out the plasticized and molded product, cool it in water to 50°C, and demold it to obtain a foamed PVC nasal plug.

[0038] After testing, the obtained product has a static friction coefficient of 0.21 for the skin on the back of the hand, a tensile strength of 5.4 MPa, an elongation of 147%, and a tear stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com