Invisible reinforcing device for concrete cantilever gallery road and reinforcing method thereof

A reinforcement device and concrete technology, applied in bridge reinforcement, bridge erection/assembly, bridge maintenance, etc., can solve problems such as high requirements for construction environment and construction level, high requirements for shear strength of superimposed surfaces, and unsuitable for scenic plank roads. , to achieve significant environmental protection, reduce construction costs, and improve construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

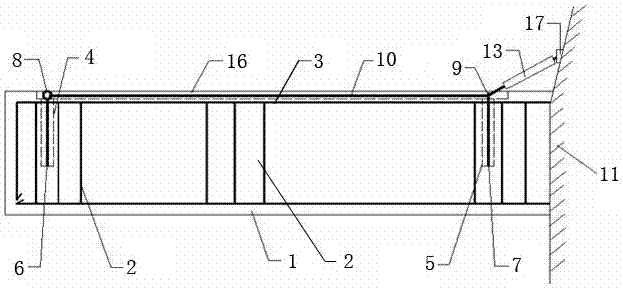

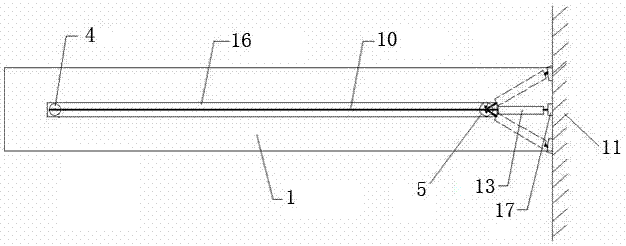

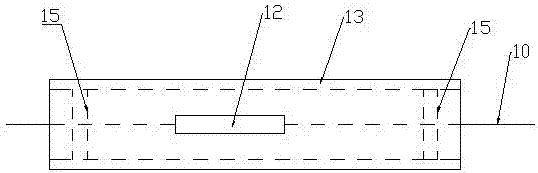

[0029] In order to facilitate the understanding of the technical means, creative features and goals achieved by the present invention, the present invention is further described below in conjunction with the schematic diagrams, but the scope of protection claimed by the present invention is not limited to the scope described in the specific implementation.

[0030] An invisible reinforcement device for concrete cantilever planks, such as figure 1 As shown, the device comprises a concrete cantilever member 1, one end of the concrete cantilever member 1 is a cantilever end fixedly connected to the rock wall 11, the other end of the concrete cantilever member 1 is a free end, and the concrete cantilever member 1 is provided with a vertical hoop The ribs 2 and the stressed steel bars 3 arranged laterally extending from the cantilever end to the free end, the stirrups 2 are densely distributed in multiples.

[0031] Among them, the free end of the concrete cantilever member 1 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com