A kind of pcf board installation adjustment and temporary fixing method

A technology for temporary fixation and installation adjustment, which is applied in the direction of formwork/formwork components, formwork/formwork/work frame, formwork/formwork/work frame connectors, etc., which can solve the difficulties of temporary fixation, low installation efficiency, installation Quality is difficult to guarantee and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

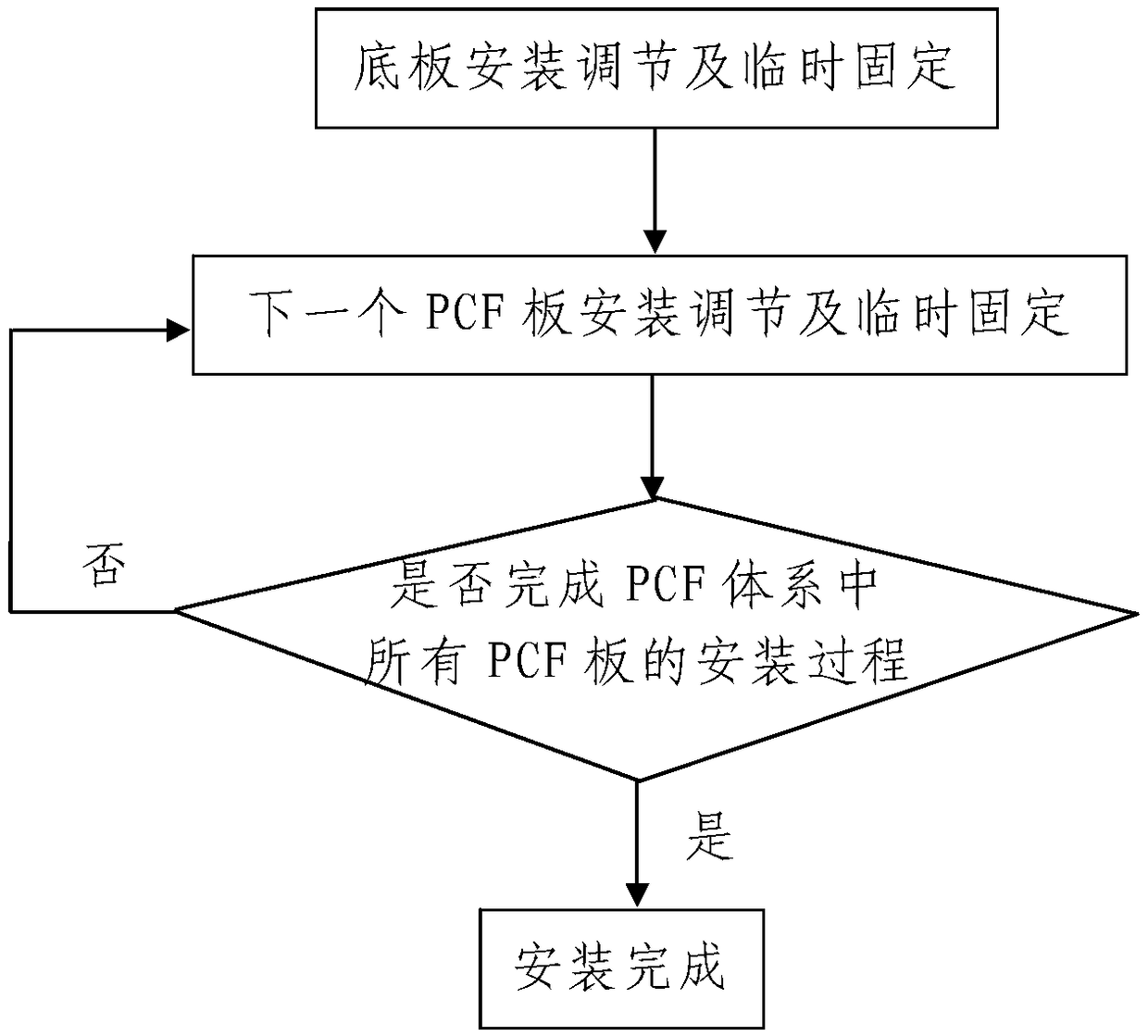

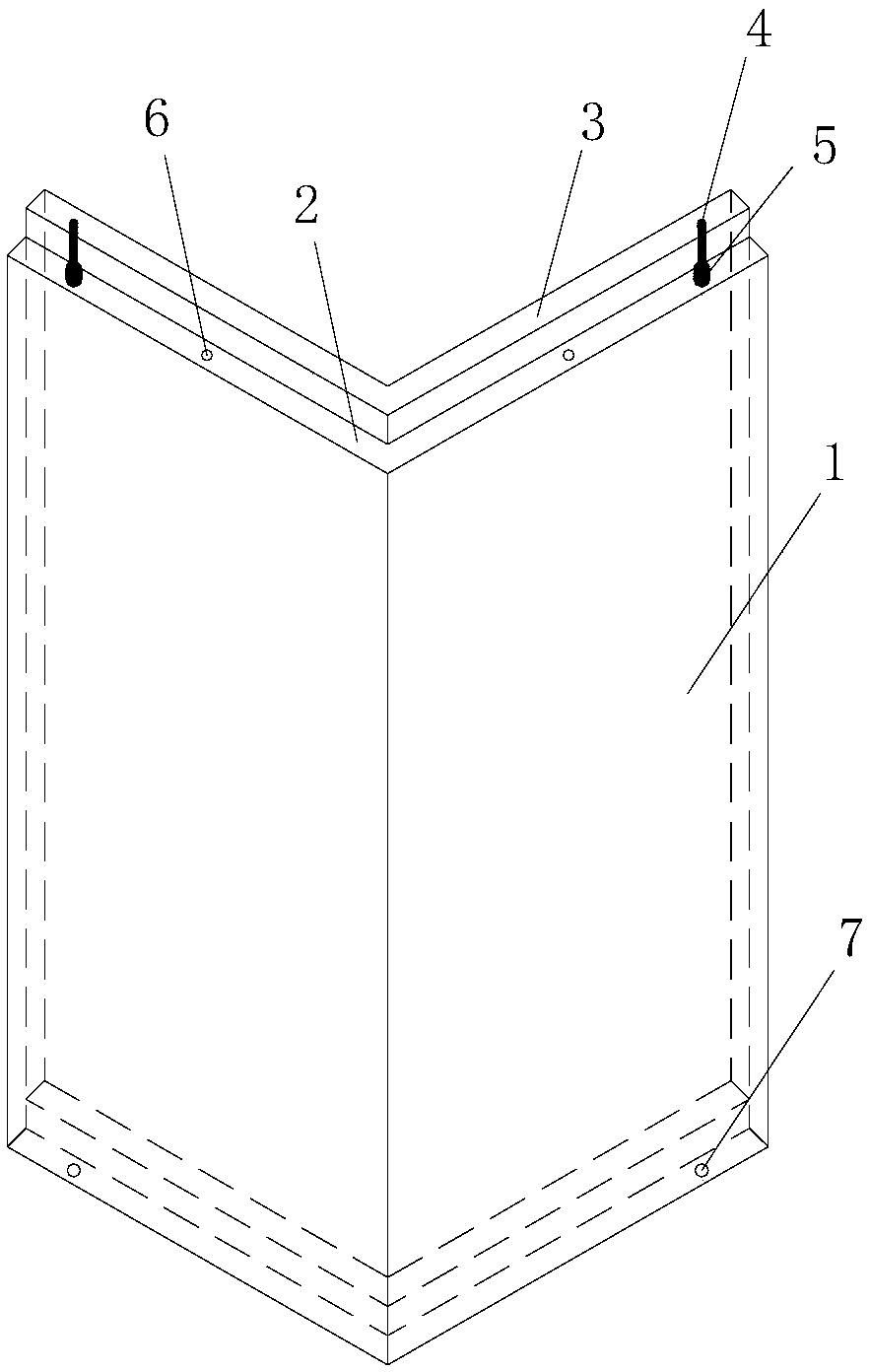

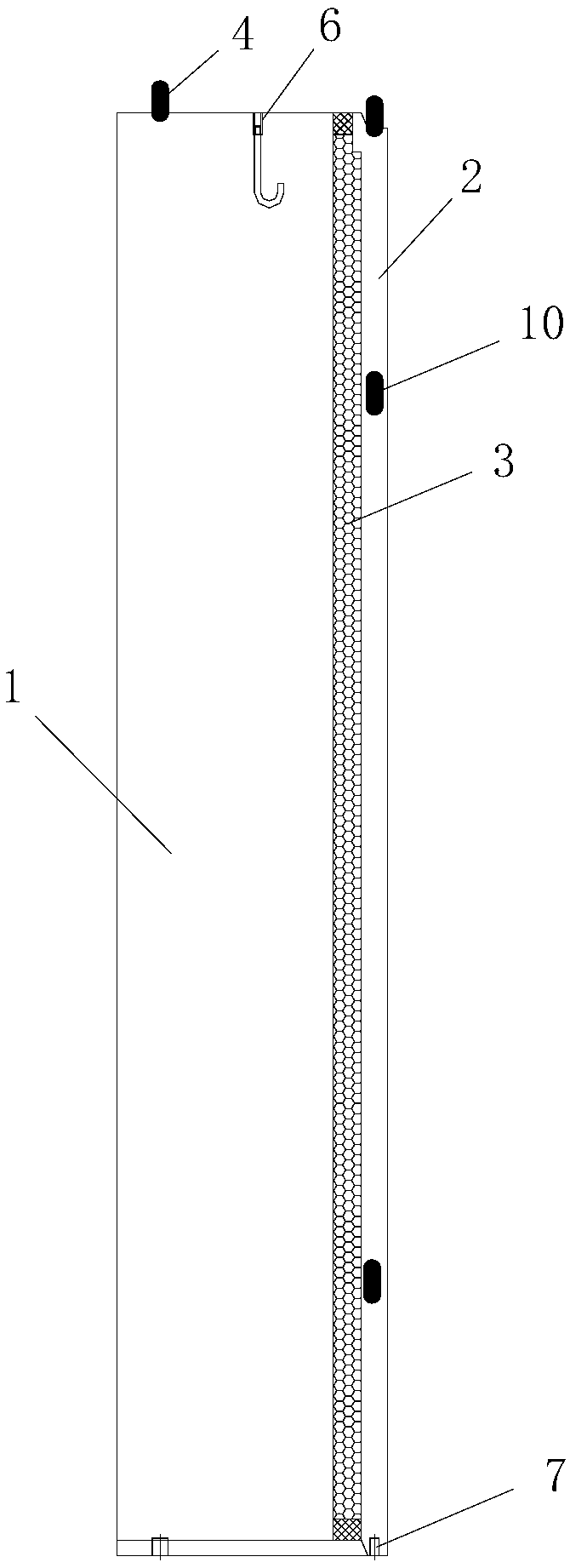

[0072] Such as figure 1 In the shown method for installation adjustment and temporary fixing of PCF boards, the number of installed PCF boards 1 is multiple, and multiple PCF boards 1 are arranged vertically and assembled into a PCF system from bottom to top. The cross-sectional structure and size of the PCF board 1 are the same; figure 2 , image 3 , Figure 4 and Figure 5, the cross-section of each PCF board 1 is rectangular, each of the PCF boards 1 includes an exterior wall panel 2 and an insulation layer 3 arranged inside the exterior wall panel 2, the exterior wall panel 2 and the insulation layer The cross-section of the layer 3 is rectangular; the upper and lower adjacent two PCF boards 1 are connected through grooves and the two are fixed by two embedded bolts 4, and the embedded bolts 4 are vertically Layout; the PCF board 1 positioned at the bottom in the PCF system is a base plate, and the PCF board 1 above the base plate in the PCF system is an upper mountin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap