Heat recovery type evaporation-condensation type water cooling unit

An evaporative condensation and chiller technology, applied in evaporators/condensers, refrigerators, heating methods, etc., can solve the problems of low heat recovery rate and low temperature of hot water recovery, so as to enhance heat exchange effect and improve exhaust gas. temperature, the effect of lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings of the description.

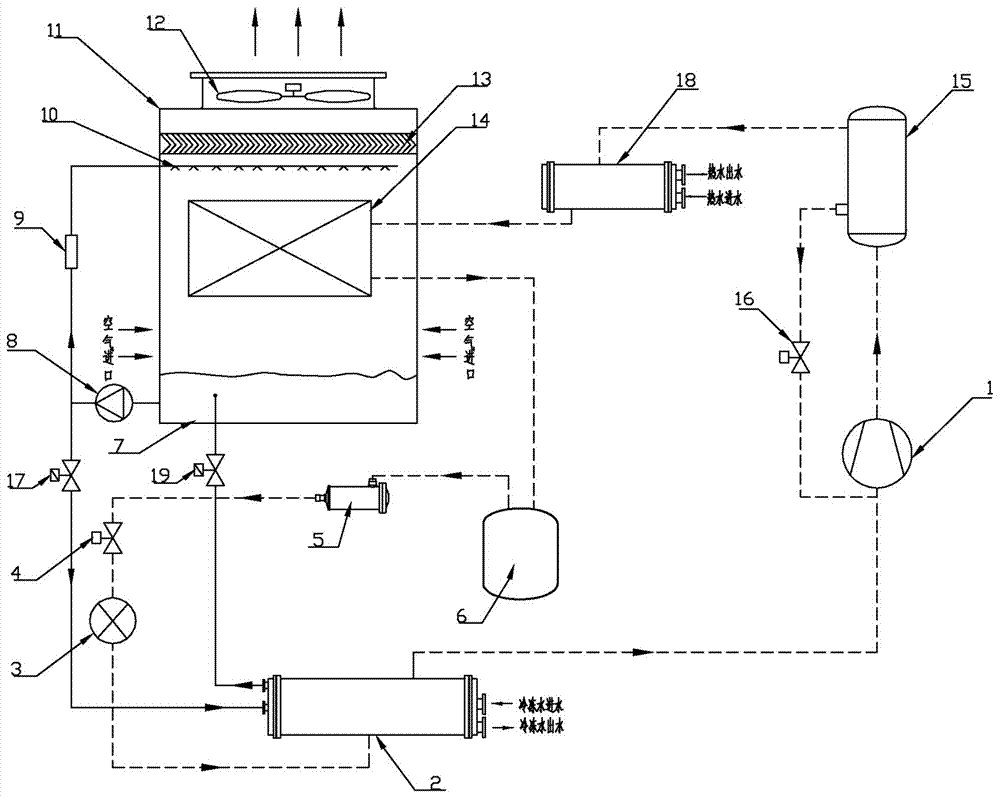

[0019] like figure 1 The shown heat recovery evaporative condensing chiller includes a compressor 1, a heat recovery device 18, an evaporative condenser 11, an expansion valve 3, and a flooded evaporator 2, and the heat recovery device 18 has refrigerants that exchange heat with each other Channel A and hot water channel. Refrigerant channel A is usually a heat exchange coil. The two ends of the hot water channel are used for hot water inlet and hot water outlet respectively. Heat exchange is performed when hot water and refrigerant flow through the heat recovery device at the same time. , the evaporative condenser 11 has a sump 7, a coil heat exchanger 14, a spray system 10, and an axial flow fan 12 arranged in order from low to high, and a spray water pipe is connected between the sump 7 and the spray system 10. The spray water pipe is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com