Self-synchronizing barcode displacement sensor and measurement method thereof

A displacement sensor and bar code technology, applied in measuring devices, instruments, optical devices, etc., can solve the problems of inconvenient maintenance, large errors, shortening the service life of sensors, etc., and achieve a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

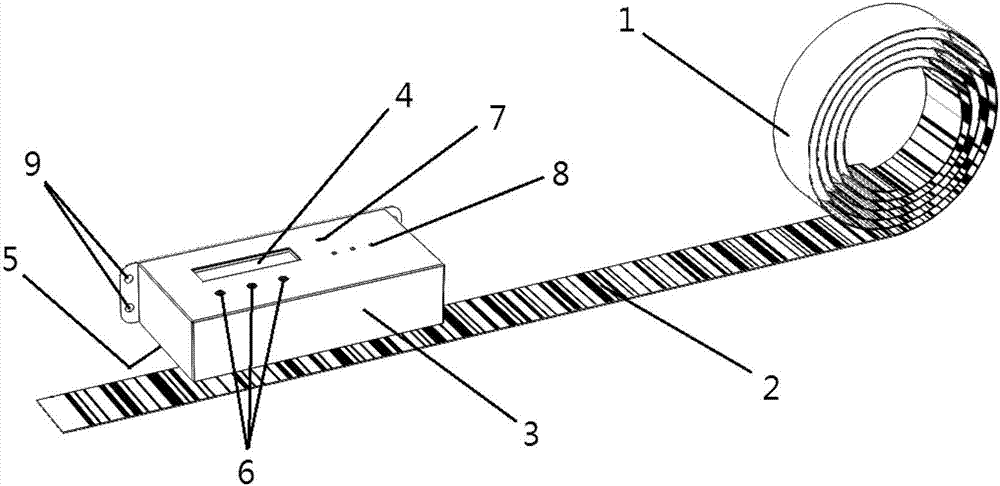

[0049] The structure diagram of the self-synchronizing barcode displacement sensor of the present invention is as follows figure 1 As shown, the self-synchronizing barcode displacement sensor of the present invention includes a reading box 3, a tape 1, and a specific one-dimensional barcode 2 printed on the tape. The reading box 3 is separated from the ruler tape 1 by a certain distance, and is kept parallel all the time, and the movement direction of the reading box 3 is consistent with the length direction of the ruler tape 1 . Among them, the reading box 3 includes a display screen 4, a function button 6, a microUSB data interface 7, and a signal indicator light 8, and a barcode reading device 5 (a CCD camera in this embodiment) is installed below, and there are two on the left and right sides respectively. Install fixing hole 9.

[0050] In this embodiment, the tape 1 is made of PC film, which has good flexibility, is suitable for installation on a flat or curved surface,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com