Device and method for testing fatigue of wheel axle

A fatigue test and wheel axle technology, applied in the field of material performance testing and research, can solve the problems of high experimental cost, difficulty in accurately predicting the fatigue performance of wheels and axle products from material fatigue data, and difficulty in application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0040] Example 1: Scaled wheel rolling contact fatigue test

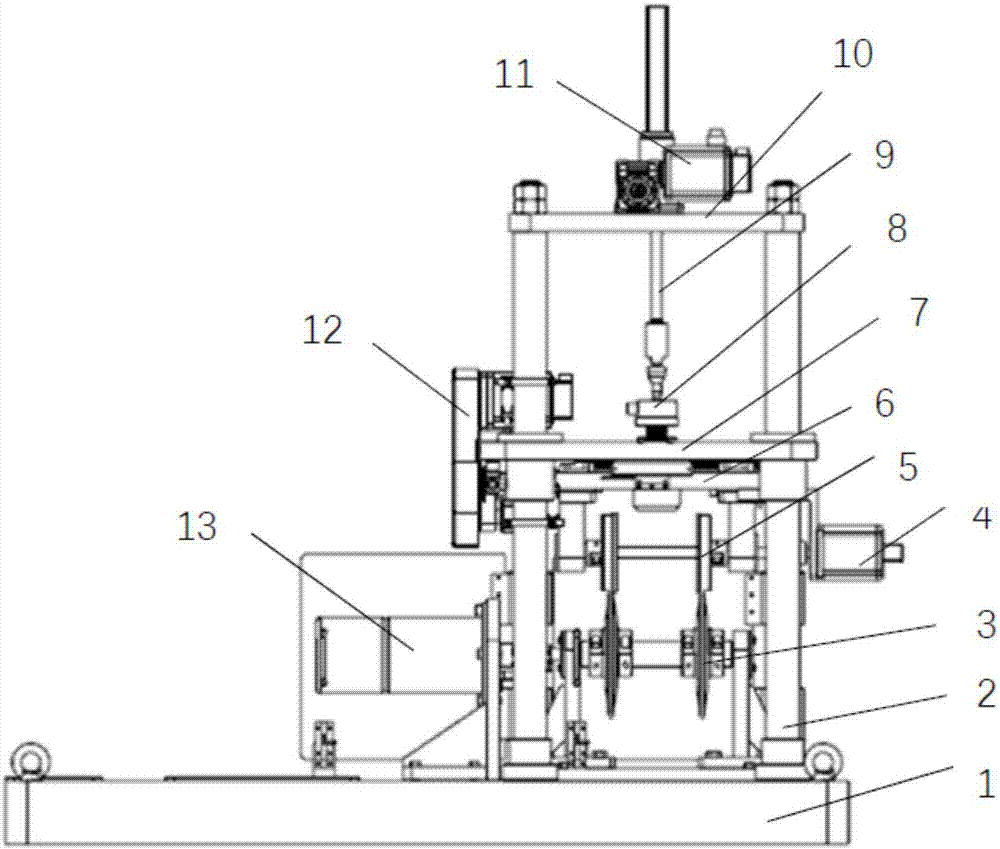

[0041] This example illustrates the composition and application method of the device in conjunction with the rolling contact fatigue test of the scaled wheel. like figure 1 As shown, the device of this embodiment includes: a scale wheel 5, a track wheel 3, a rotary drive mechanism, a vertical loading system, a damping and braking mechanism 4 and a controller.

[0042] Scale wheel 5 and track wheel 3, in wheel-rail contact fatigue and friction-wear test, scale wheel 5 is used for simulating actual wheel, and track wheel 3 is used for simulating the actual track that actual wheel runs; Scale wheel 5 samples It is based on the actual wheel to be tested, and is made in proportion to the actual wheel. Generally, the scaled wheel 5 is required to maintain geometric similarity with the actual wheel except for its size; the track wheel is sampled from the actual track on which the actual wheel runs. , that is, the track w...

example 2

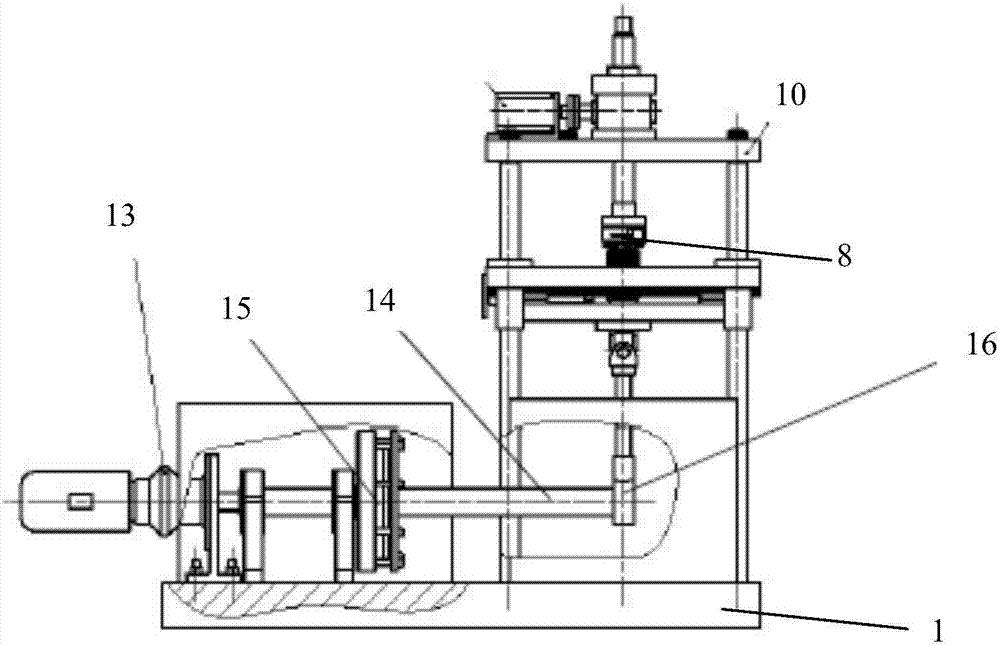

[0060] Example 2: Scaled axle cantilever rotational bending fatigue test

[0061] This example also provides a wheel axle fatigue test device, the test device except the parts described in Example 1, such as figure 2 As shown, it can further include: a scaled axle 14 and a simulated wheel 15 used in the axle fatigue test, the scaled axle 14 is sampled from the actual axle to be tested, and is made in proportion to the actual axle, and the simulated wheel 15 is used In simulating the effect of the wheel on the actual axle during actual operation; during the axle fatigue test, one end of the scaled axle 14 is connected with the rotary drive mechanism, and the other end is the loading end, which is connected with a loading end bearing 16; the vertical loading system is also used for A load is applied to the loading end of the scaled axle 14 through the loading bearing 16; the simulated wheel 15 is press-fitted and connected to the scaled axle 14, and the simulated wheel 15 press...

example 3

[0069] Example 3: Scaled wheel web fatigue test

[0070] This example also provides a wheel axle fatigue test device, which, in addition to the components described in examples 1 and 2, further includes: a scaled wheel and a simulated axle used in the wheel web fatigue test, the scaled wheel The spoke plate is sampled from the actual full-size wheel spoke plate and scaled with the actual wheel’s spoke plate. The simulated axle is used to simulate the effect of the axle on the actual wheel during actual operation; in the wheel spoke plate fatigue test , the structure of the device is roughly similar to that of Example 2, which can be referred to figure 2 As shown, one end of the simulated axle is connected to the rotary drive mechanism, and the other end is the loading end, which is connected to a bearing of the loading end; the vertical loading system is also used to apply load to the loading end of the simulated axle through the loading bearing; the scaled wheel pressure In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com