Intelligent high-voltage DC contactor

A high-voltage DC, contactor technology, used in instruments, relays, electromagnetic relays, etc., can solve the problem of asynchronous auxiliary contacts and actuators, and achieve the effect of improving anti-surge interference, ensuring system safety, and reducing failure rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

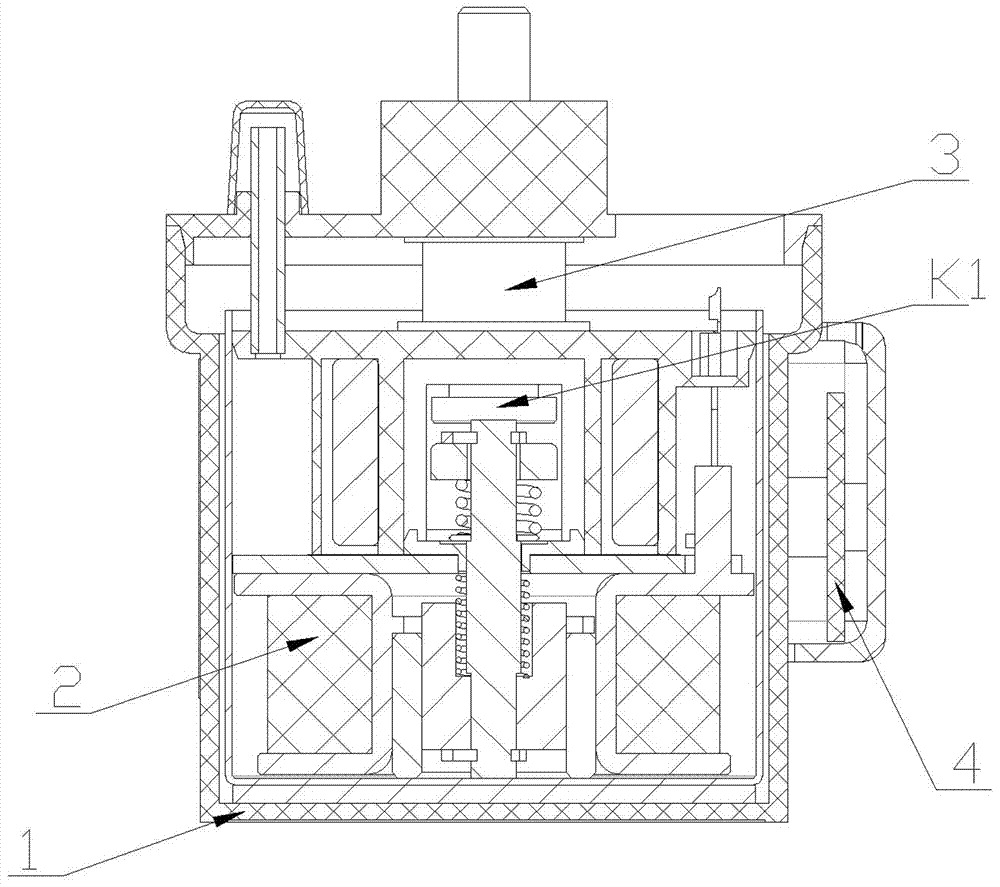

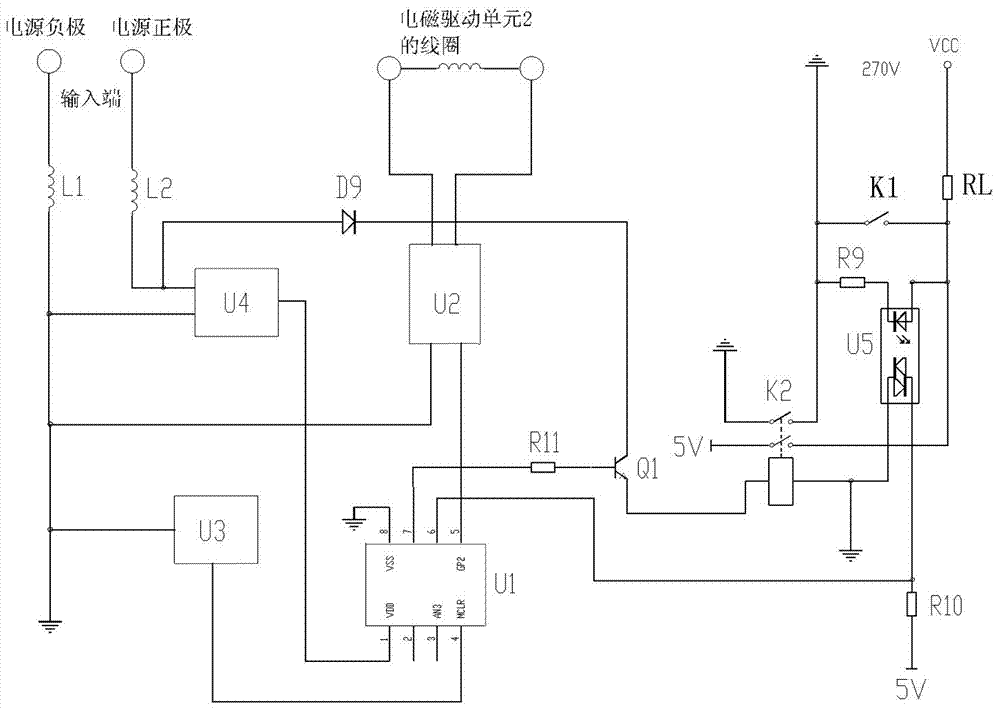

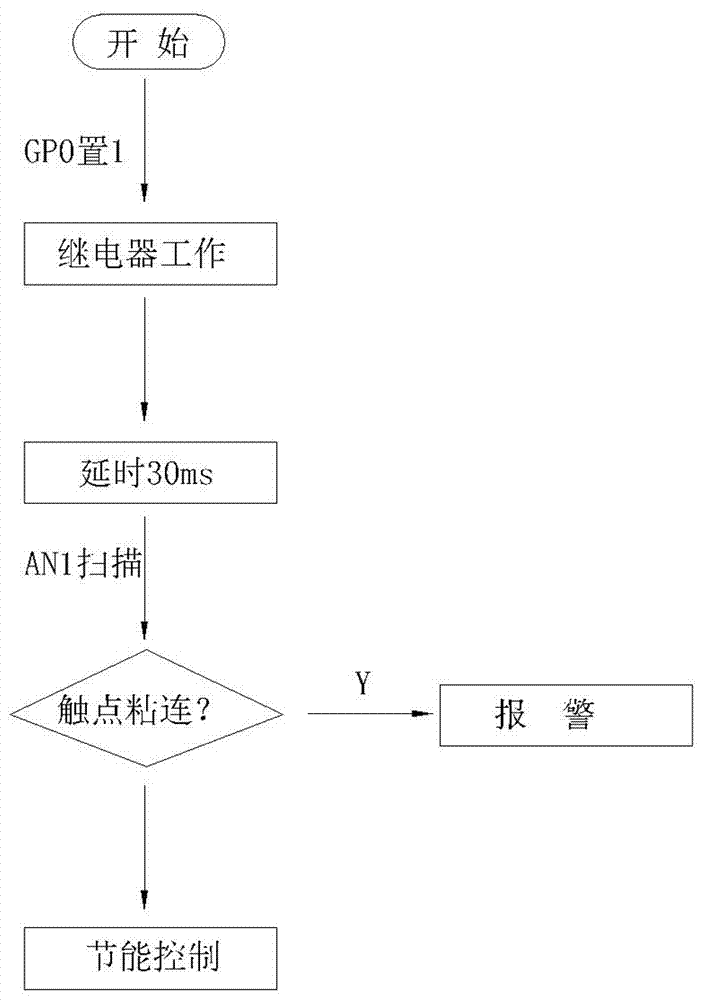

[0013] combine figure 1 and figure 2 As shown, the present invention provides an intelligent high-voltage DC contactor, including a housing 1, in which a main contact K1, an electromagnetic drive unit 2, and an actuator 3 are provided; in the housing 1, a adhesion detection control unit is also provided 4. The adhesion detection control unit 4 includes MCU module U1, contactor energy-saving control module U2, triode Q1, photocoupler U5, relay K2, remote communication module U3 and voltage stabilizing module U4 that provides regulated power supply; the positive pole and negative pole of the working power supply Connect to the input terminal of the voltage stabilizing module U4 through the inductors L1 and L2 respectively, and the voltage stabilizing module U4 outputs a stable voltage of 5V; the output interface of the MCU module U1 is connected to the base of the transistor Q1 through the resistor R11, and the collector of the transistor Q1 passes through the diode D9 Connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com