Miniature multilayer ceramic low pass filter

A technology of low-pass filter and multi-layer ceramics, which is applied in the direction of multi-terminal pair network, impedance network, electrical components, etc., can solve the problem that the size and area of the device cannot be effectively reduced, and achieve superior performance, low cost, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

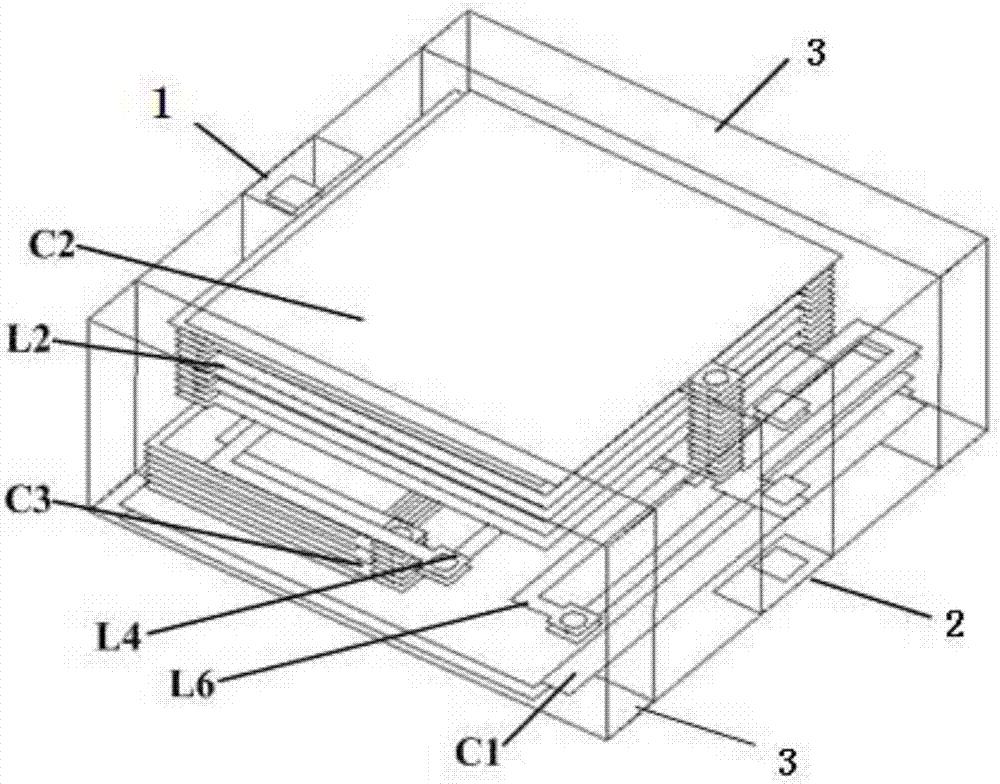

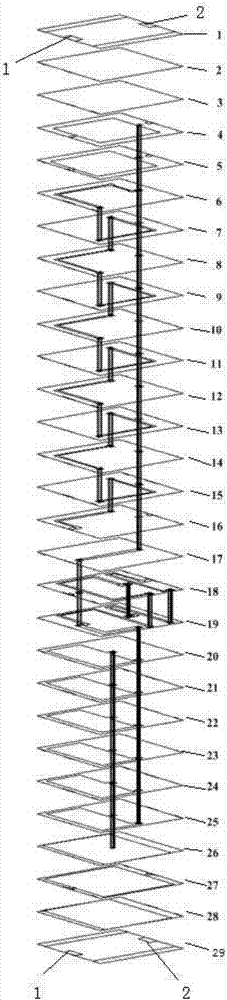

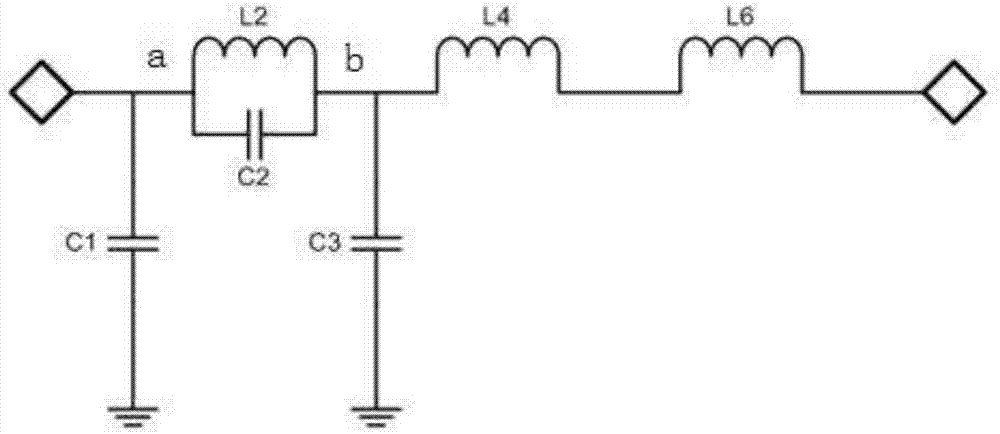

[0016] like Figure 1-4 As shown, the miniature multilayer ceramic low-pass filter of this embodiment includes a laminate composed of multilayer dielectric substrates and a filter circuit arranged in the laminate. Adjacent dielectric substrates are connected to each other through conductive bands and via holes. The dielectric substrate has at least one ground layer, and its surface is provided with an input terminal 1 and an output terminal 2. The filter circuit includes inductors L2, L4, L6 and capacitors C1, C2, and C3. The inductor L2 is connected in parallel with the capacitor C2. The parallel terminals are the a terminal connected to the input terminal 1 and the b terminal connected in series with the inductance L4, one end of the inductance L6 is connected to the inductance L4, the other end is connected to the output terminal 2, one end of the capacitor C1 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com