Glass welding material and preparation method thereof

A glass solder and solder technology, applied in the field of welding materials, can solve the problems of changing the original characteristics of glass powder, environmental pollution, damage to human health, etc., to avoid environmental pollution and damage to the human body, and to avoid changes in the performance of glass powder Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

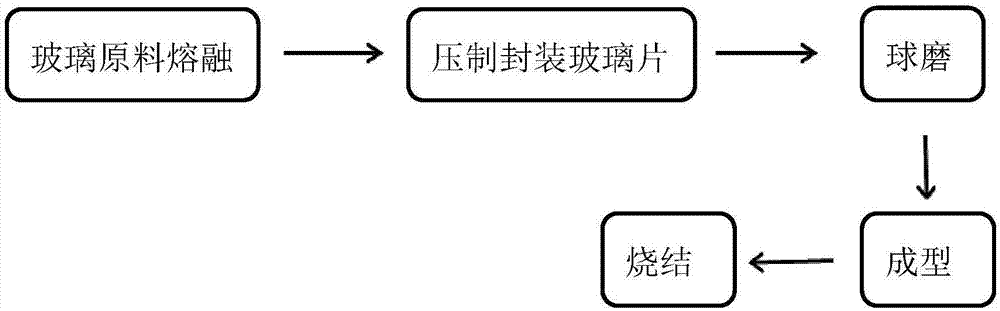

[0028] One aspect of the present invention provides a kind of preparation method of glass solder, comprises the following steps:

[0029] a) Ball milling: ball milling the packaged glass sheet to make glass powder;

[0030] b) Forming: pressing the glass powder to form a solder blank;

[0031] c) Sintering: the solder body is sintered to obtain the glass solder.

[0032] In the preparation method provided by the present invention, the glass powder obtained after ball milling is directly pressed into shape, avoiding the use of organic matter such as binders, thus avoiding the problem of changing the properties of the glass powder due to the addition of binders, and avoiding the Environmental pollution and harm to the human body caused by volatilization of the adhesive during use.

[0033] In a preferred embodiment of the present invention, the particle size of the glass powder after ball milling is 2-10 microns.

[0034] In a preferred embodiment of the present invention, th...

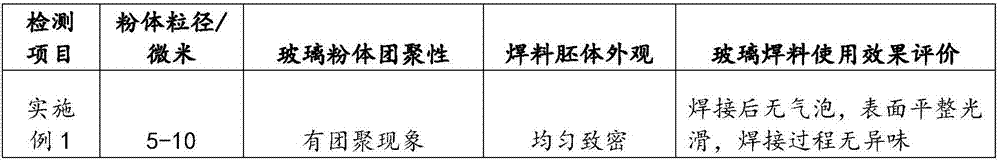

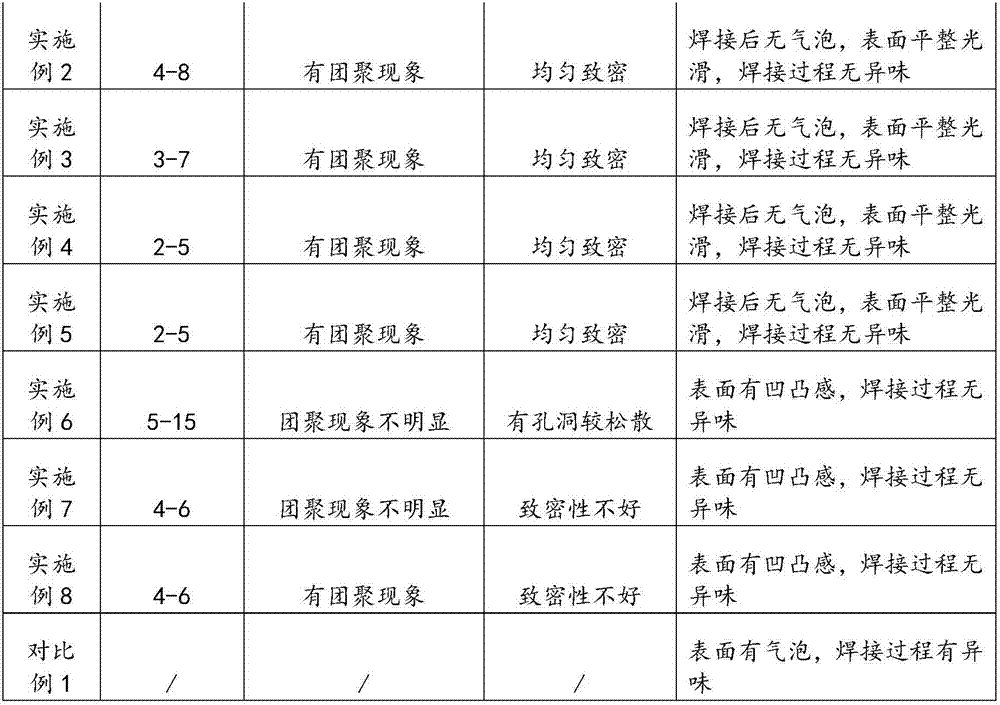

Embodiment 1

[0067] A preparation method of glass solder, comprising the following steps:

[0068] a) fusing glass raw materials to prepare molten glass, and cooling and rolling the molten glass into encapsulating glass sheets;

[0069] b) Ball milling: ball milling the encapsulated glass sheet to make glass powder;

[0070] During ball milling, the rotating speed of the ball mill was 50 rpm, and the ball milling time was 5 hours;

[0071] The temperature of the ball mill is 20°C and the humidity is 30%;

[0072] c) Forming: pressing the glass powder to form a solder blank;

[0073] During the molding process, the pressure of the pressed glass powder is 20MPa;

[0074] d) Sintering: the solder body is sintered to obtain the glass solder.

Embodiment 2

[0076] A preparation method of glass solder, comprising the following steps:

[0077] a) fusing glass raw materials to prepare molten glass, and cooling and rolling the molten glass into encapsulating glass sheets;

[0078] b) Ball milling: ball milling the encapsulated glass sheet to make glass powder;

[0079] During ball milling, the rotating speed of the ball mill is 70 rpm, and the ball milling time is 3 hours;

[0080] The temperature of the ball mill is 20°C and the humidity is 50%;

[0081] c) Forming: pressing the glass powder to form a solder blank;

[0082] During the molding process, the pressure of the pressed glass powder is 30MPa;

[0083] d) Sintering: the solder body is sintered to obtain the glass solder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com