Liquid crystal polyester resin composite and preparation method and application thereof

A technology of resin composite and liquid crystal polyester, which is applied in the field of liquid crystal polyester resin composite and its preparation, can solve the problems of the prepared products such as the performance decline of electronic components, high surface resistivity, easy accumulation, etc., and achieve excellent mechanical strength and The effect of workability, low surface resistivity and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] On the other hand, the embodiment of the present invention provides a preparation method of the liquid crystal polyester resin compound in the above embodiment. In one embodiment, the preparation method of the liquid crystal polyester resin compound includes the following steps:

[0039] Step S01: weighing the raw materials of each component according to the type and content of the components contained in the liquid crystal polyester resin compound described above;

[0040] Step S02: melt, knead and extrude the weighed raw materials of each component.

[0041]Wherein, the content of each component weighed in the above step S01 and the selected components are the same as those described above in the liquid crystal polyester resin compound, and will not be repeated here in order to save space.

[0042] In the above step S02, the raw materials of each component are fully dispersed and interact with each other under the action of high pressure and high heat of melt kneadin...

Embodiment 1

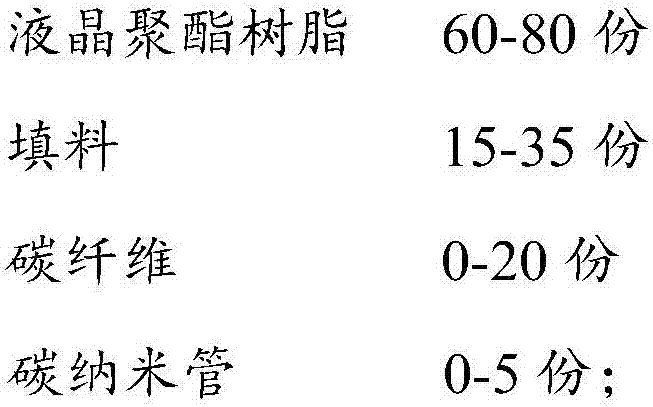

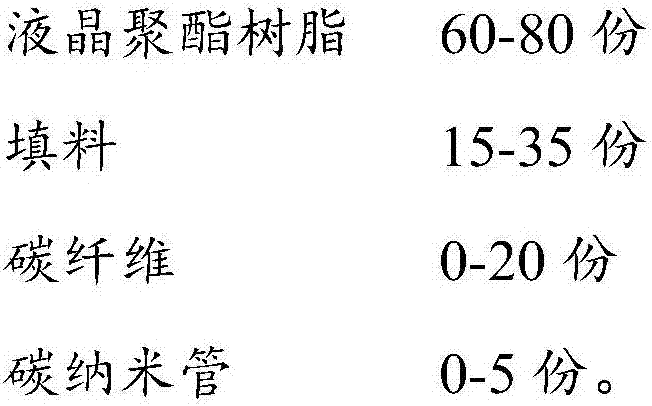

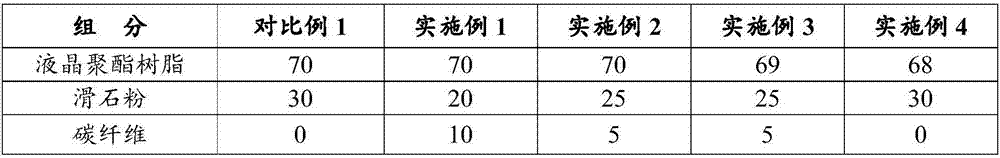

[0050] This embodiment provides a liquid crystal polyester resin compound and a preparation method thereof. The liquid crystal polyester resin compound includes components and contents in parts by weight in Table 1 below. in,

[0051] The average molecular weight of liquid crystal polyester resin is 50000, the size of talc powder is 300 mesh, the size of carbon fiber is 4mm in length, and the volume resistivity is 1.0×10 -3 Ω·cm, the size of carbon nanotubes is 5-15nm in diameter, 30-0μm in length, and the volume resistivity is (1.0-1.5)×10 -1 Ω·cm.

[0052] The preparation method of liquid crystal polyester resin compound is as follows:

[0053] S11. Preparation of liquid crystal polyester resin: the structural units of the resin are p-hydroxybenzoic acid, terephthalic acid, biphenol, 6-hydroxy-2-naphthoic acid and isophthalic acid, and the acetylating agent is acetic anhydride;

[0054] S12. According to the parts by weight described in Example 1 in Table 1, 70 parts of ...

Embodiment 2

[0057] This embodiment provides a liquid crystal polyester resin compound and a preparation method thereof. The liquid crystal polyester resin compound includes components and contents in parts by weight in Table 1 below. in,

[0058] The average molecular weight of liquid crystal polyester resin is 50000, the size of talc powder is 300 mesh, the size of carbon fiber is 4mm in length, and the volume resistivity is 1.0×10 -3 Ω·cm.

[0059] The preparation method of liquid crystal polyester resin compound is as follows:

[0060] S21. Preparation of liquid crystal polyester resin: the structural units of the resin are p-hydroxybenzoic acid, terephthalic acid, biphenol, 6-hydroxy-2-naphthoic acid and isophthalic acid, and the acetylating agent is acetic anhydride;

[0061] S22. According to the parts by weight described in Example 2 in Table 1, 70 parts of liquid crystal polyester resin (full aromatic liquid crystal polyester resin, Jiangsu Water Special Material Manufacturing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap