Metal organic framework/polymer nanofiber composite membrane material and preparation method thereof

A metal-organic framework and nanofiber membrane technology, applied in the direction of fiber type, fiber treatment, non-woven fabrics, etc., can solve the problems of powder-like limited practical application and instability of metal-organic framework materials, and achieve poor stability and easy Adjustable effect of operation, mechanical stability and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

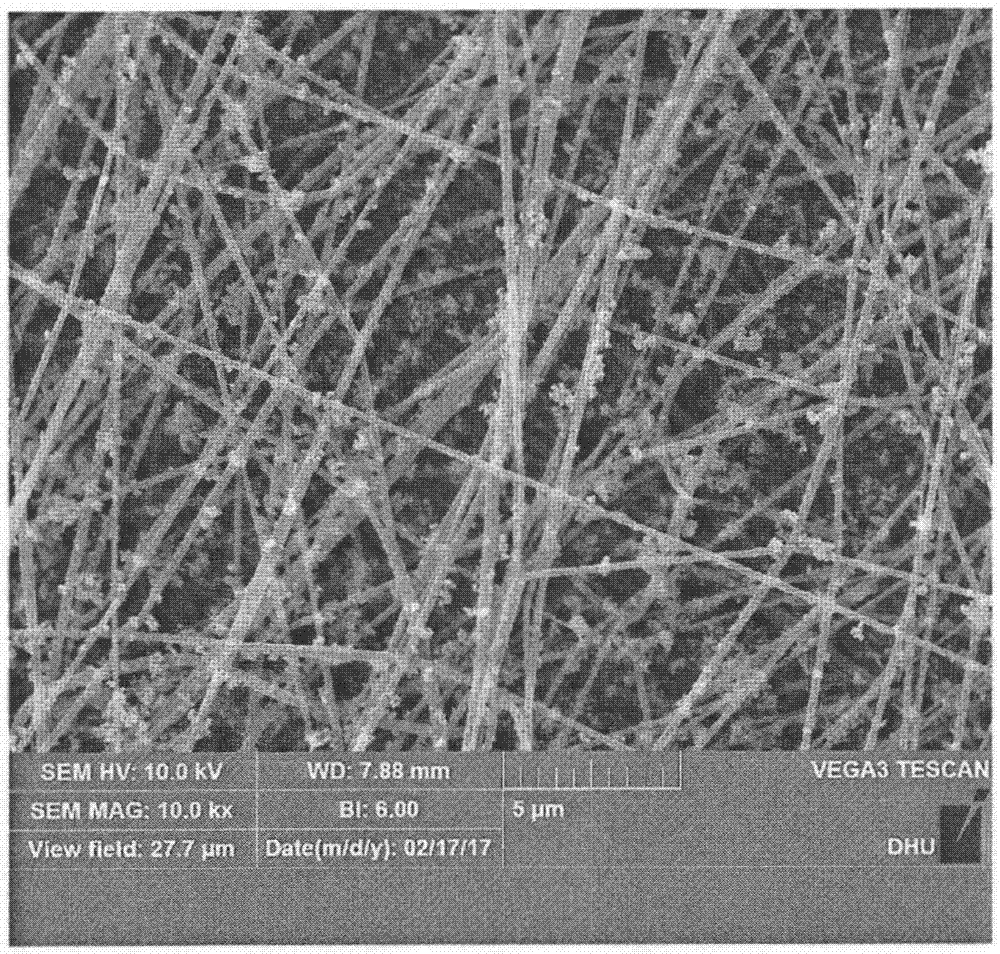

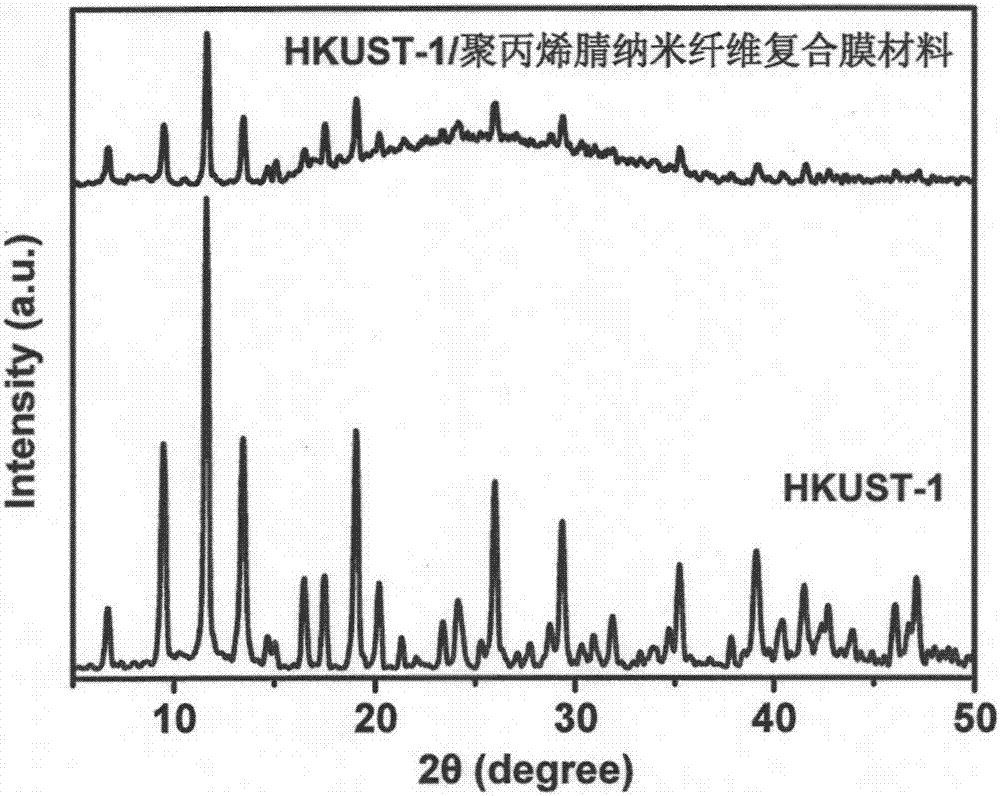

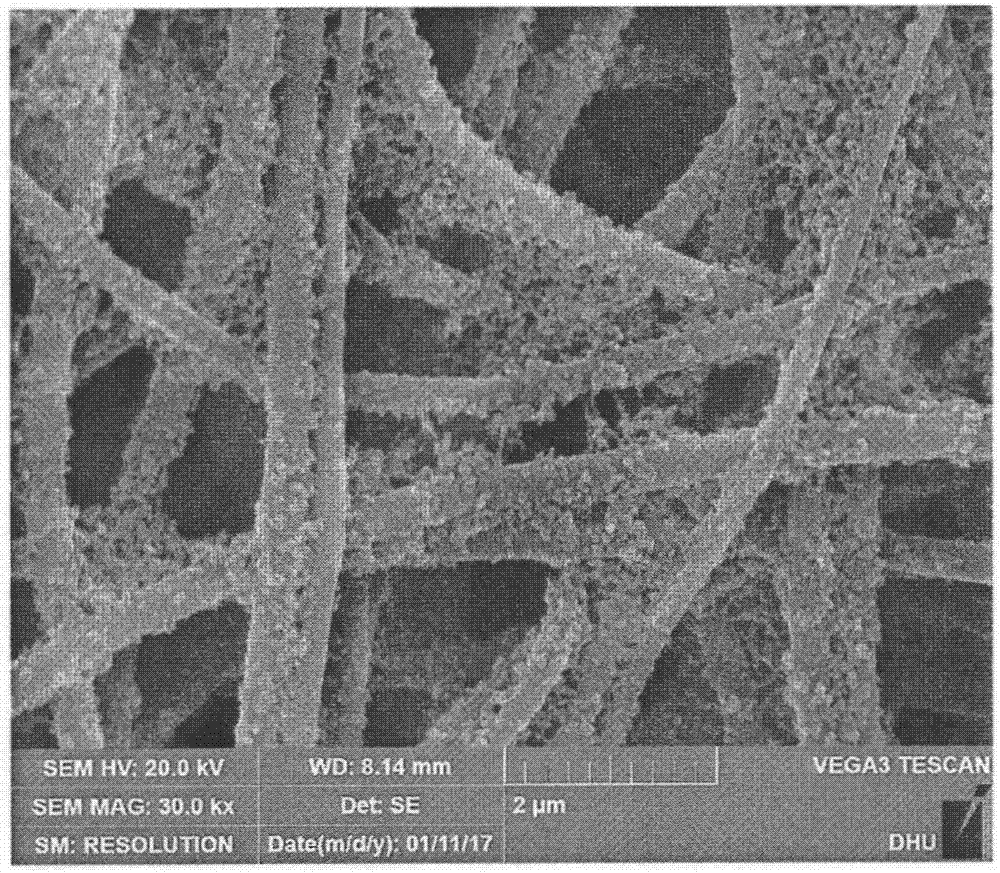

[0034]A metal-organic framework / polymer nanofiber composite membrane material includes a polymer nanofiber membrane, and a metal-organic framework layer grows on the surface of nanofibers in the polymer nanofiber membrane.

[0035] The preparation method of the metal organic framework / polymer nanofiber composite membrane material is:

[0036] (1) Preparation of polymer nanofiber membrane: Dissolve 1.0 g of polyacrylonitrile in 9.0 g of dimethyl sulfoxide in a stirred tank at a room temperature of 25° C., and stir for 16 hours at a speed of 1000 rpm to obtain a polyacrylonitrile with a mass fraction of 10%. Raw material for electrospinning. The obtained electrospinning raw material was added to the electrospinning device, and the electrospinning was carried out under the conditions of the static voltage of 28kV, the flow rate of the syringe pump of 1mL / h, and the distance between the spinneret and the receiving screen of 20cm to obtain polyacrylonitrile nanoparticles. Fiber me...

Embodiment 2

[0044] A metal-organic framework / polymer nanofiber composite membrane material includes a polymer nanofiber membrane, and a metal-organic framework layer grows on the surface of nanofibers in the polymer nanofiber membrane.

[0045] The preparation method of the metal organic framework / polymer nanofiber composite membrane material is:

[0046] (1) Preparation of polymer nanofiber membrane: at room temperature of 25°C, dissolve 1.2g of polyacrylonitrile in 8.8g of N,N-dimethylformamide in a stirred tank, stir at 800rpm for 12h, and obtain a mass fraction of 8% electrospun raw material. The obtained electrospinning raw material was added to an electrospinning device, and electrospinning was carried out under the conditions of a static voltage of 25kV, a flow rate of a syringe pump of 0.8mL / h, and a distance of 20cm between the spinneret and the receiving screen to obtain polyacrylonitrile nanofibrous membrane.

[0047] (2) Hydrolysis: prepare the hydrolyzate that contains the ...

Embodiment 3

[0053] A metal-organic framework / polymer nanofiber composite membrane material includes a polymer nanofiber membrane, and a metal-organic framework layer grows on the surface of nanofibers in the polymer nanofiber membrane.

[0054] The preparation method of the metal organic framework / polymer nanofiber composite membrane material is:

[0055] (1) Preparation of polymer nanofiber membrane: at room temperature of 25°C, dissolve 1.2g of polyacrylonitrile in 8.8g of N,N-dimethylacetamide in a stirred tank, and stir for 20h at a speed of 1200rpm to obtain a mass fraction of 12% electrospun raw material. The obtained electrospinning raw material was added to an electrospinning device, and electrospinning was carried out under the conditions of a static voltage of 30kV, a flow rate of a syringe pump of 1mL / h, and a distance of 20cm between the spinneret and the receiving screen to obtain polyacrylonitrile nanoparticles. Fiber membrane.

[0056] (2) Hydrolysis: prepare the hydrolyz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com