Low-voltage winding structure of on-load capacitance regulation transformer, winding method of low-voltage winding structure and transformer

A low-voltage winding and transformer technology, applied in the direction of transformer/inductor coil/winding/connection, inductor/transformer/magnet manufacturing, transformer, etc., can solve the problems of high cost and can not effectively reduce space, etc. Withstand short-circuit ability and good manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

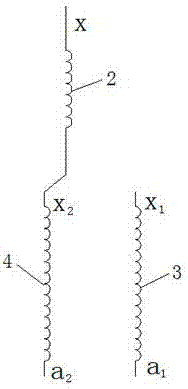

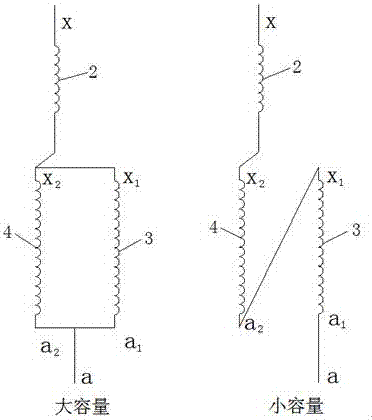

[0039] Such as figure 1 As shown, the low-voltage winding structure of the on-load capacity regulating transformer of the present invention is divided into three sections: the low-voltage I section 3 and the low-voltage II section 4 for serial parallel, and the low-voltage III section 2 for the common coil, the low-voltage III section and the Low pressure stage II pass x 2 connected together, and the other ends are independently led out.

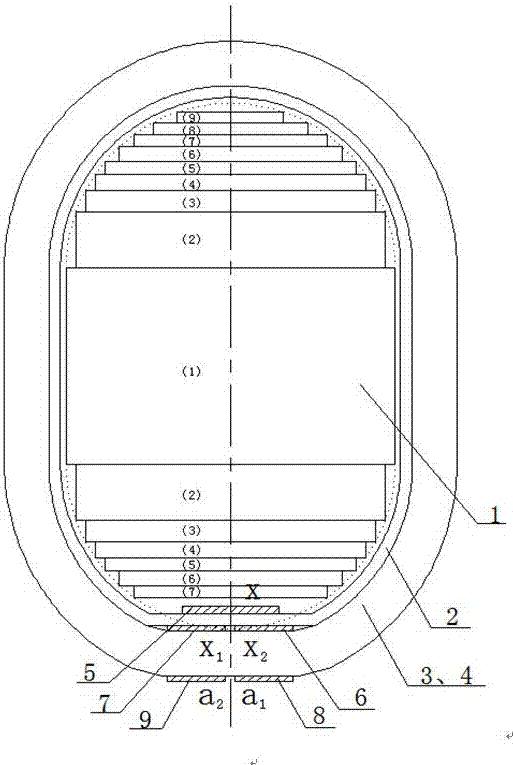

[0040] Such as image 3 and Figure 4 , Low-voltage III section 2, low-voltage I section 3 and low-voltage II section 4 are all made of copper foil, and copper bars are drawn out. The copper foil cross-sectional area and height of the low-voltage I section 3 and the low-voltage II section 4 are equal, and the copper foil cross-sectional area of the low-voltage III section 2 is 1.9 to 2.2 times that of the low-voltage I section 3 or the low-voltage II section 4. . The copper foil height of low-voltage section III section 2 is equal to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com