Cutting, paint spraying and air drying device

A technology of air-drying device and air-drying box, which is applied in the direction of spraying device, paint spraying room, charging device, etc., which can solve the problems of danger, loss, and unsafe cutting of wood for operators, and achieve personal safety protection, simple operation, and avoid indirect The effects of sexual touching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

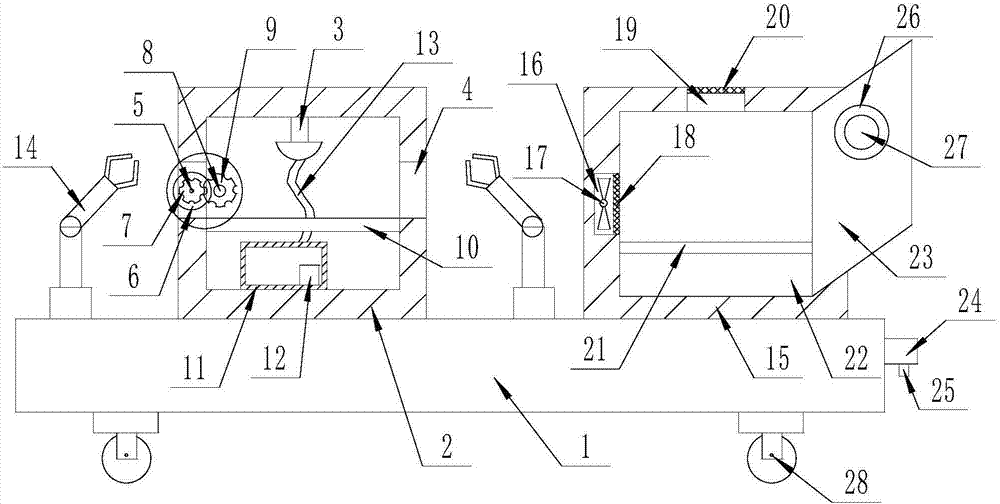

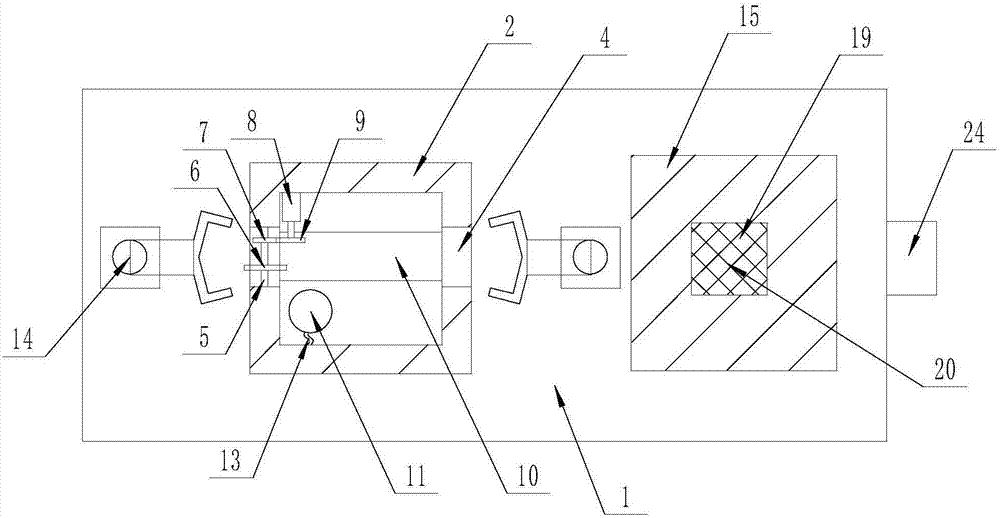

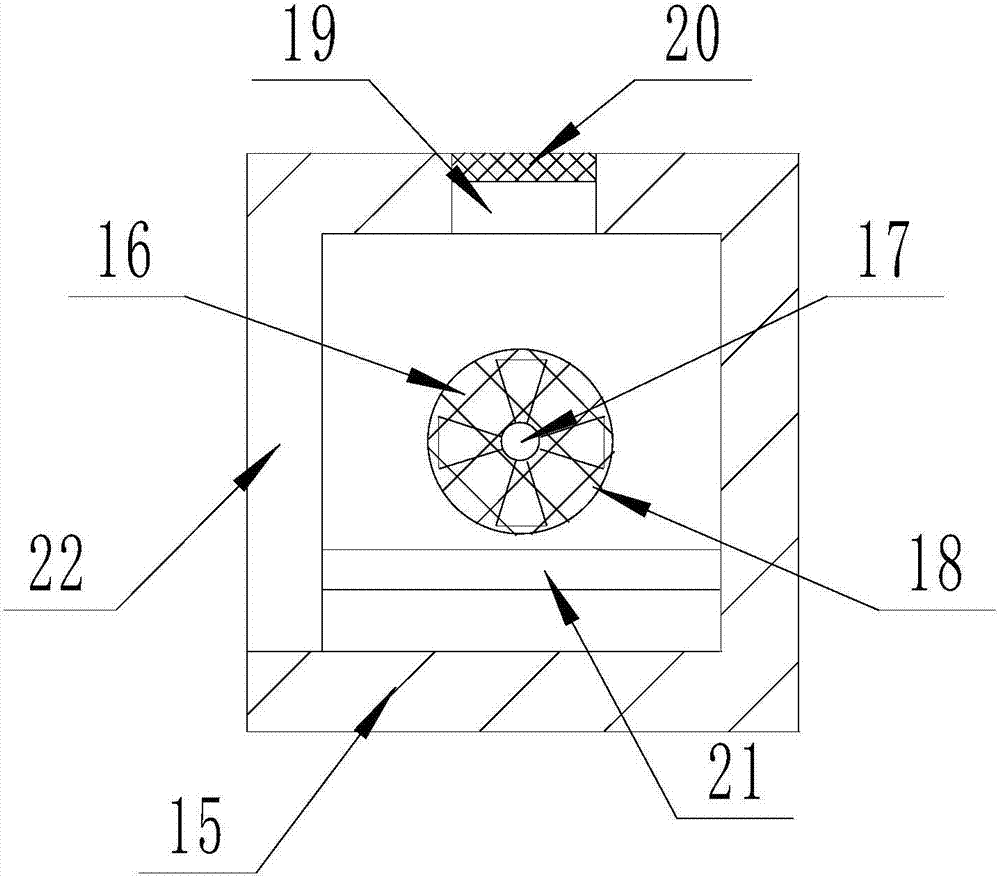

[0013] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, a cutting and spraying paint air-drying device includes a rectangular workbench (1), the upper surface of the rectangular workbench (1) is provided with a cutting and spraying system, and the cutting and spraying system is arranged on the upper surface of the rectangular workbench (1) a rectangular box (2), a nozzle (3) arranged on the upper surface of the rectangular box (2), a rectangular opening (4) processed on both sides of the rectangular box (2), and one of the rectangular openings ( 4) The rotating rod (5), the circular cutter head (6) set on the rotating rod (5), the driven gear on the rotating rod (5) and located on the side of the circular cutter head (6) (7), the rotating motor (8) arranged in the rectangular box (2) with the rotating end in the horizontal direction, the driving gear (9) arranged at the rotating end of the rotating motor (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com