Dry granular distributing machine and dust cover

A distributing machine and dry granule technology, which is applied in the field of distributing machines, can solve the problems of lack of residual material recovery device and dust isolation device, environmental pollution, waste, etc., and achieve the effects of saving dry granules, improving product quality, and preventing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

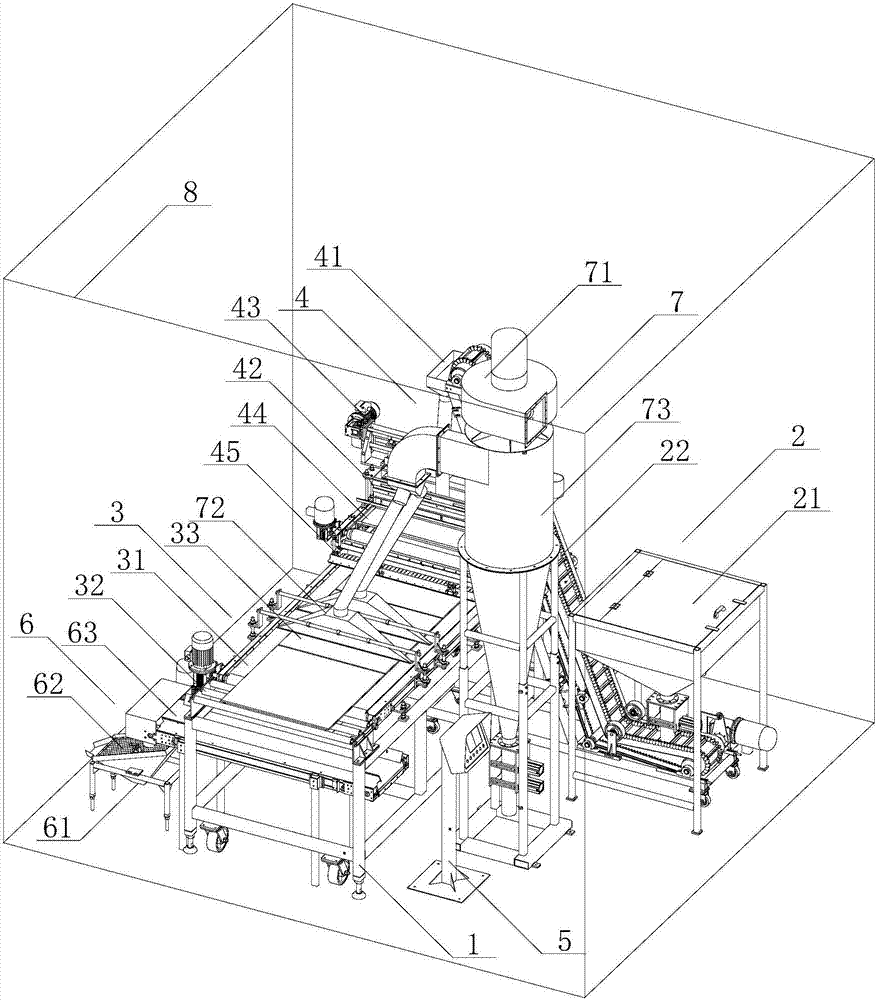

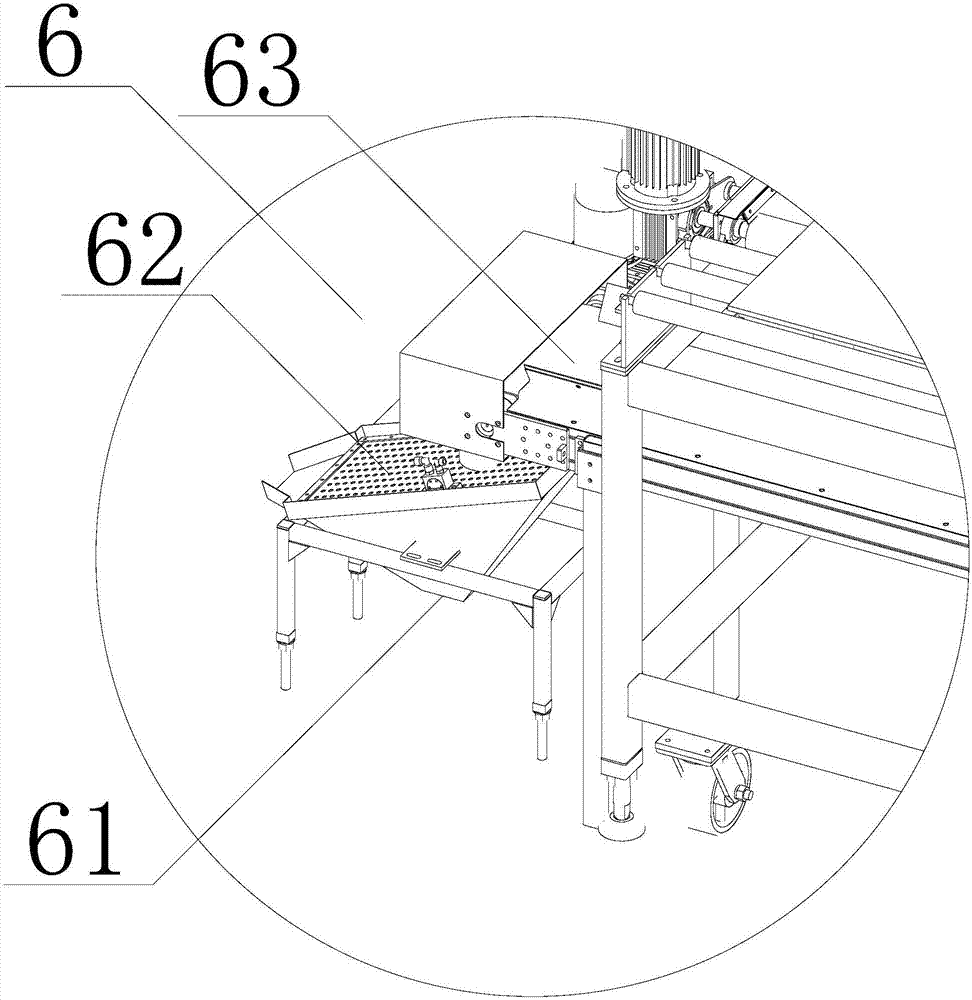

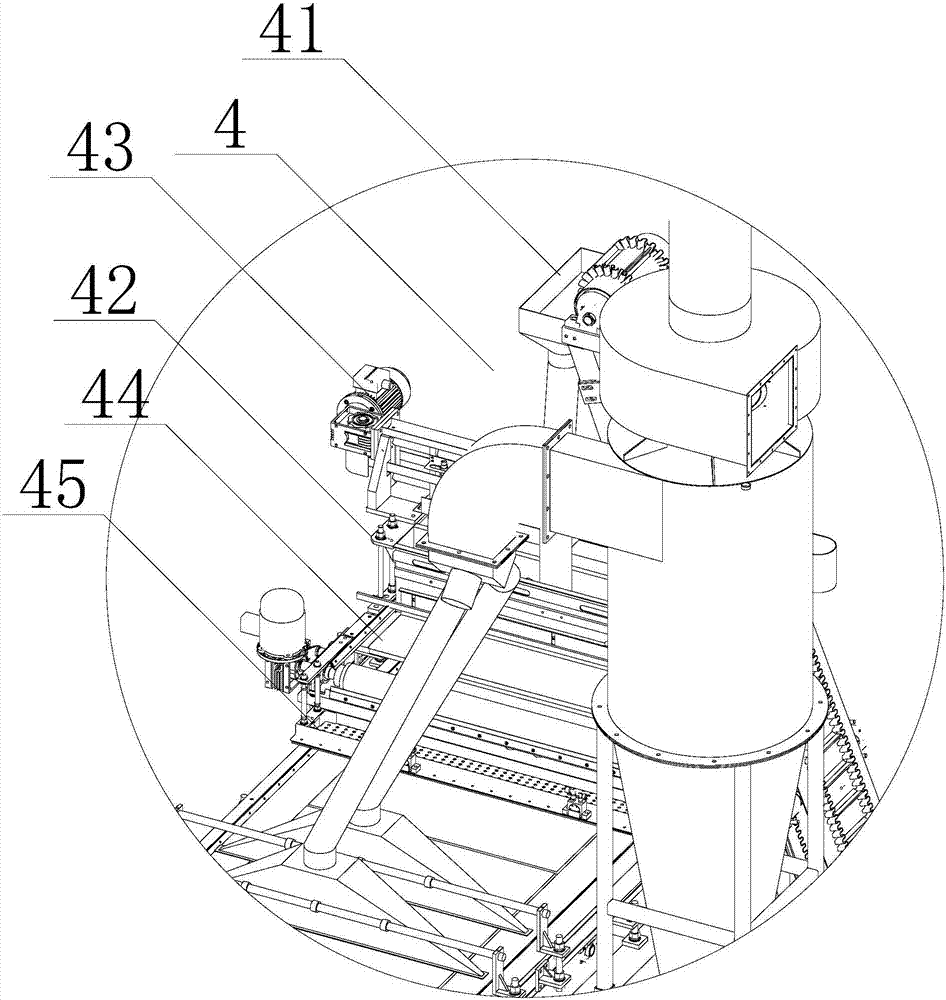

[0024] Such as figure 1 As shown, in the embodiment, the present invention provides a dry grain distributing machine, including a frame 1, a raw material supply device 2, a conveying device 3, a distributing device 4, and a control device 5, and also includes, for reclaiming the remaining ceramic tiles at the output end The recovery device 6 and the suction device 7 for absorbing the tile residue during the conveying process, the recovery device 6 is located below the output end of the conveying device 3, and the suction device 7 is arranged between the output end and the input end of the conveying device 3. The material suction device 7 and the recovery device 6 can take away the redundant dry particles from the ceramics during the cloth distributing process and recycle them, which improves the use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com