Spiral scale

A screw scale and screw technology, which is applied in the field of dynamic metering equipment for powder materials, can solve problems such as product quality degradation, punching, and powder flow speed interference, and achieve the effects of prolonging service life, reducing costs, and preventing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

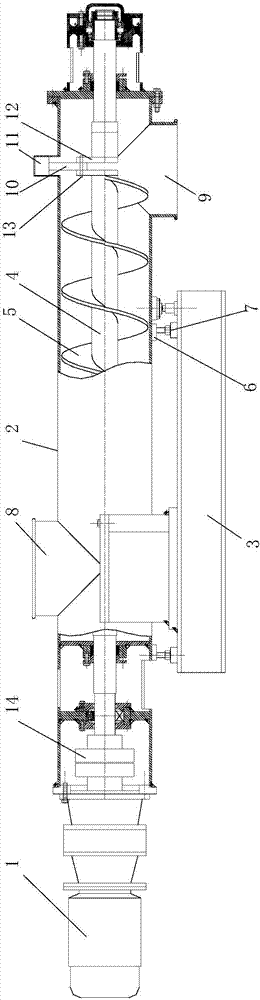

[0016] See figure 1 The present invention has a speed reducer 1, a spiral cylinder 2 and a weighing mechanism 3; the rotating shaft of the speed reducer 1 is connected with the screw shaft 4 in the spiral cylinder 2; The discharge port 8 is provided with a discharge port 9 communicating with the screw cylinder 2 below the discharge end; an integrated spiral blade 5 is provided on the circumferential surface of the screw shaft 4; the weighing mechanism 3 passes through a pressure sensor 6 and a connecting plate with a lever fulcrum 7 is arranged below the screw cylinder 2; there is a pushing mechanism directly above the discharge port 9 at the discharge end of the screw cylinder 2; the pushing mechanism includes a pushing connecting rod 10, a piston block 11 and a connecting block 12; the connecting block 12 has two pieces, and Arranged side by side, the connecting block 12 is fixed to the screw shaft 4; one end of the push connecting rod 10 is hinged to the two connecting bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com