Aligned conveying device of composite boards

A technology of conveying device and composite board, which is applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., can solve the problems of maintenance labor and time, poor stability, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings, so that those skilled in the art to which the invention pertains can easily implement these embodiments. However, the present invention can also be implemented in various different forms, so the present invention is not limited to the embodiments described below. In addition, in order to more clearly describe the present invention, components not connected to the present invention will be omitted from the drawings.

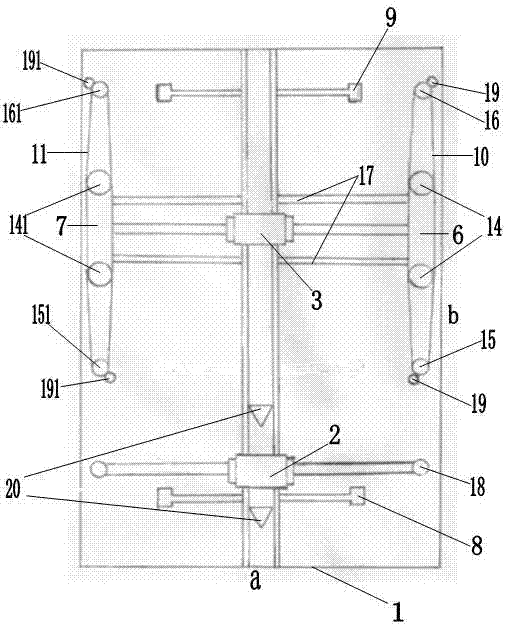

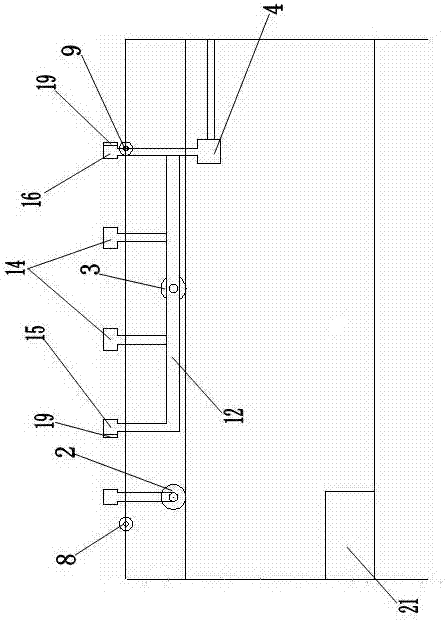

[0033] Such as Figure 1-2 Shown: the power module includes a double-headed oil cylinder 1, a double-headed oil cylinder 2, 3, a constant speed motor 4, and a constant speed motor 2 5;

[0034] The execution module includes a driven wheel 18, a centering device 6, a centering device 7, a supporting wheel 8, and a supporting wheel 9;

[0035] The control module includes an infrared sensor 20 and a PLC control system 21;

[0036] The centering...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap