Expansive concrete for construction of super long concrete structure

A technology of concrete structure and expansive concrete, applied in the field of expansive concrete, can solve the problems of prolonging the construction period, corroding steel bars, affecting the safety of the structure, etc., so as to reduce the generation of cracks in concrete structures, reduce the generation of structural cracks, and reduce the limiting dry shrinkage rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

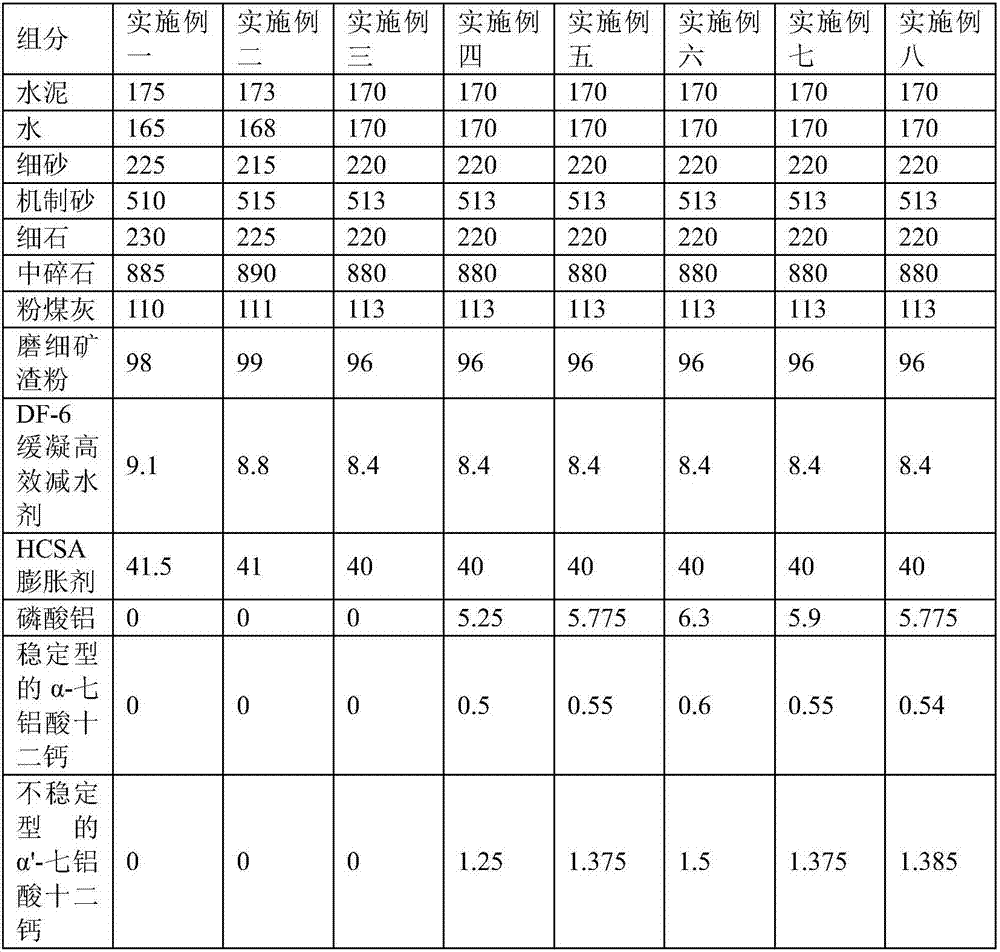

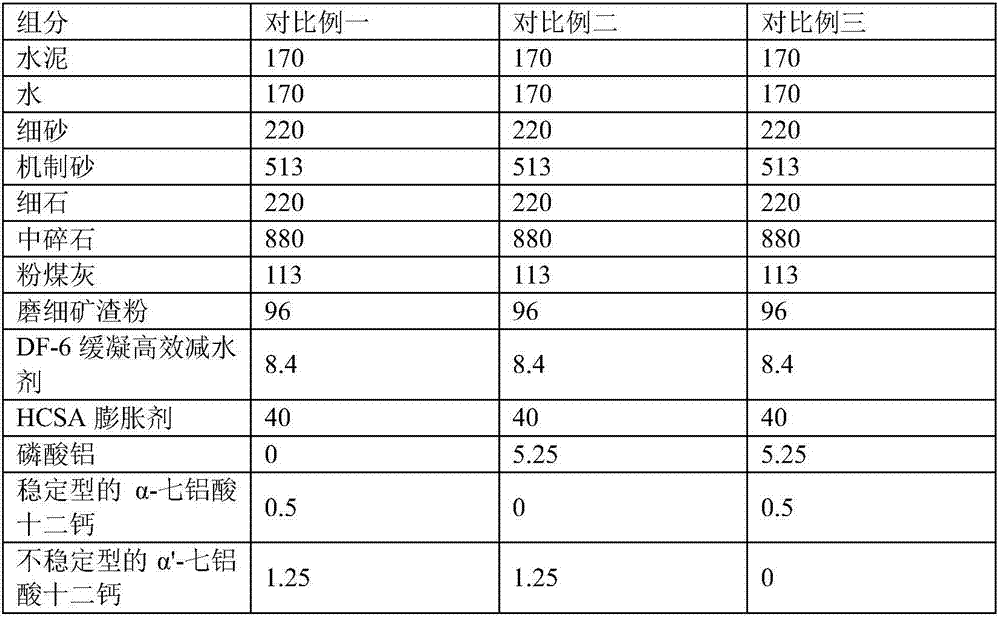

[0030] The present invention is described in further detail below in conjunction with embodiment. It should be understood that the preparation methods described in the examples of the present invention are only used to illustrate the present invention, rather than limit the present invention, and under the premise of the concept of the present invention, simple improvements to the preparation methods of the present invention all belong to the scope of protection of the present invention .

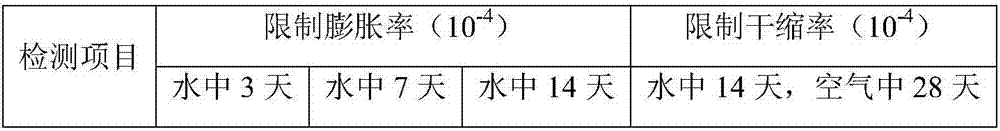

[0031] The concrete of the present invention has micro-expansion performance, and the design and setting of the limiting expansion rate are very important. If the expansion rate is too small, the ability to compensate for shrinkage will be insufficient, and seamless construction will be difficult to achieve. If the expansion rate is too large, it will have a significant impact on the strength of the concrete. The design of micro-expansion concrete is mainly to add an appropriate amount of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com