Non-bearing insulating brick

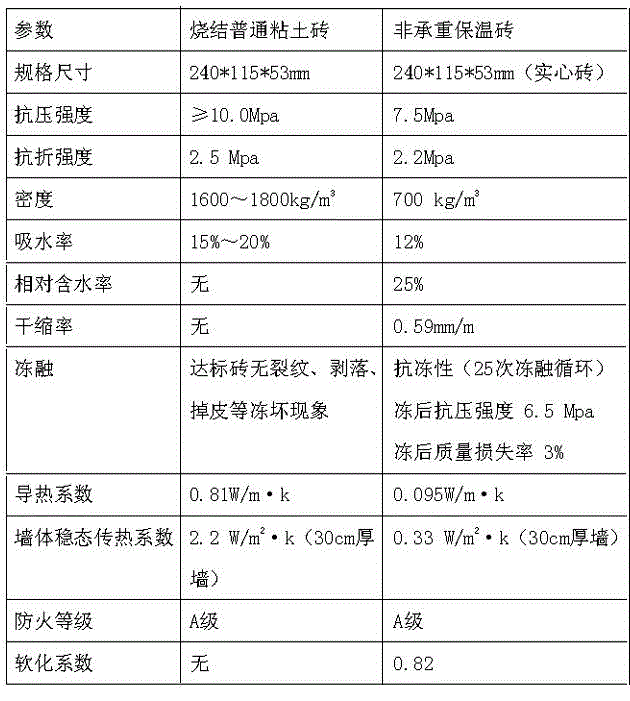

A thermal insulation brick, non-load-bearing technology, applied in the field of building bricks, can solve the problems of poor fire-retardant performance of polystyrene board, long construction period, affecting thermal insulation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] The raw materials used in the non-load-bearing thermal insulation bricks involved in the present invention are composed of 35% ceramsite, 25% vitrified microbeads, 10% pumice, 12% cement, 3% fly ash, 5% lime, and FTC phase. Variable energy storage insulation material 3%, gypsum 3%, asbestos 3% and admixture 1%. The admixture is composed of 3 parts of concrete early-strength agent, 4 parts of concrete air-entraining agent, 1 part of concrete water reducing agent and 2 parts of cement water repellent in parts by weight. The particle size of the crushed pumice stone is 5-10mm, the length of asbestos is 5-10mm.

[0010] The steps for making bricks are as follows: 1. Pre-mix the dry material, mix and stir the raw material in a forced mixer for 5 minutes, and mix the raw material evenly to obtain a powdery material; 2. Add water and stir, and the amount of water added is 6% of the total weight of the raw material. %, stir for 5 minutes until the material is viscous; 3. Unloa...

Embodiment 2

[0012] The raw materials used in the non-load-bearing thermal insulation bricks involved in the present invention are composed of ceramsite 43%, vitrified microbeads 20%, pumice 14%, cement 8%, fly ash 5%, lime 3%, FTC phase Variable energy storage insulation material 2%, gypsum 2%, asbestos 1% and admixture 2%. The admixture is composed of 4 parts of concrete early-strength agent, 3 parts of concrete air-entraining agent, 2 parts of concrete water reducing agent and 1 part of cement water repellent in parts by weight. The particle size of the crushed pumice stone is 5-10mm, the length of asbestos is 5-10mm.

[0013] The steps for making bricks are as follows: 1. Pre-mix dry materials, mix and stir the raw materials in a forced mixer for 5 minutes, and stir the raw materials evenly to obtain powdery materials; 2. Add water and stir, and the amount of water added is 10% of the total weight of raw materials. %, stir for 6 minutes until the material is viscous; 3. Unload the mat...

Embodiment 3

[0015] The raw materials used in the non-load-bearing thermal insulation bricks involved in the present invention are composed of 39% ceramsite, 22% vitrified microbeads, 13% pumice, 10% cement, 4% fly ash, 4% lime, and FTC phase. Variable energy storage insulation material 2.5%, gypsum 2.5%, asbestos 2% and admixture 1%. The admixture is composed of 3.5 parts of concrete early-strength agent, 3.5 parts of concrete air-entraining agent, 1.5 parts of concrete water reducing agent and 1.5 parts of cement water repellent in parts by weight. The particle size of the crushed pumice stone is 5-10mm, the length of asbestos is 5-10mm.

[0016] The steps for making bricks are as follows: 1. Pre-mix dry materials, mix and stir the raw materials in a forced mixer for 5 minutes, and stir the raw materials evenly to obtain powdery materials; 2. Add water and stir, and the amount of water added is 8% of the total weight of raw materials. %, stir for 6 minutes until the material is viscous;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com