Preparation method of high-efficiency polycarboxylate superplasticizer

A polycarboxylate and superplasticizer technology, which is applied in the field of preparation of high-efficiency polycarboxylate superplasticizers, can solve the problems of poor dispersion of polycarboxylate superplasticizers, and achieve improved fluidity, compactness, and compatibility Good performance, improve the effect of flexural and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The embodiment of the present invention provides a preparation method of high-efficiency polycarboxylate superplasticizer, comprising:

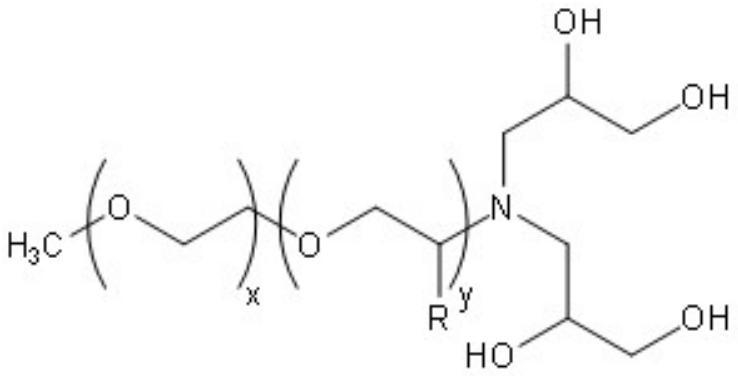

[0018] Under nitrogen atmosphere, take 60gCH 3 [OCH 2 CH 2 ] 6 [OCH 2 CH(CH 3 )] 29 NH 2 Put it into the flask and heat it to 130°C in an oil bath. With stirring, add 8 mL of glycidyl alcohol dropwise within 50 minutes. After the addition is completed, keep stirring at the temperature for 18 hours to react to obtain intermediate a.

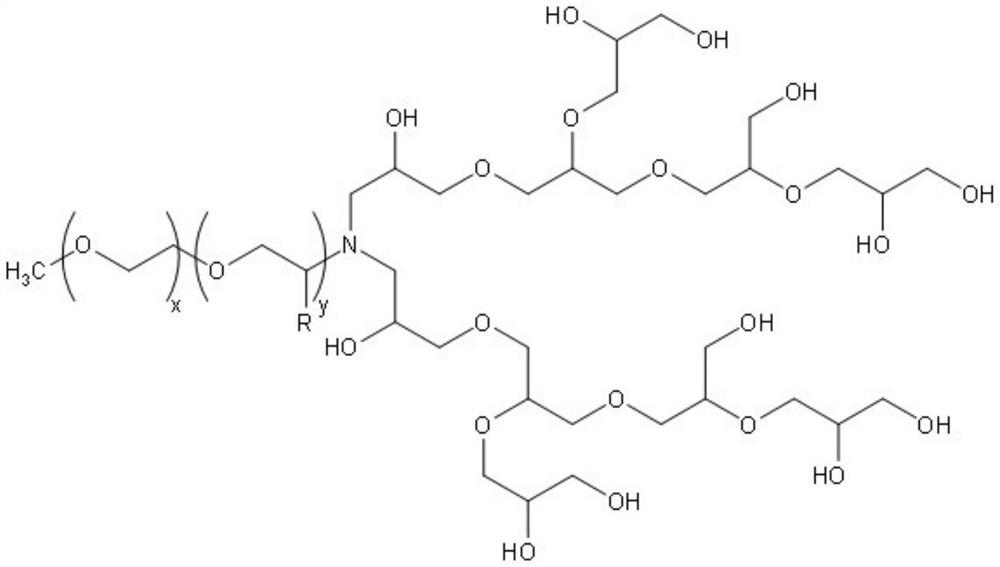

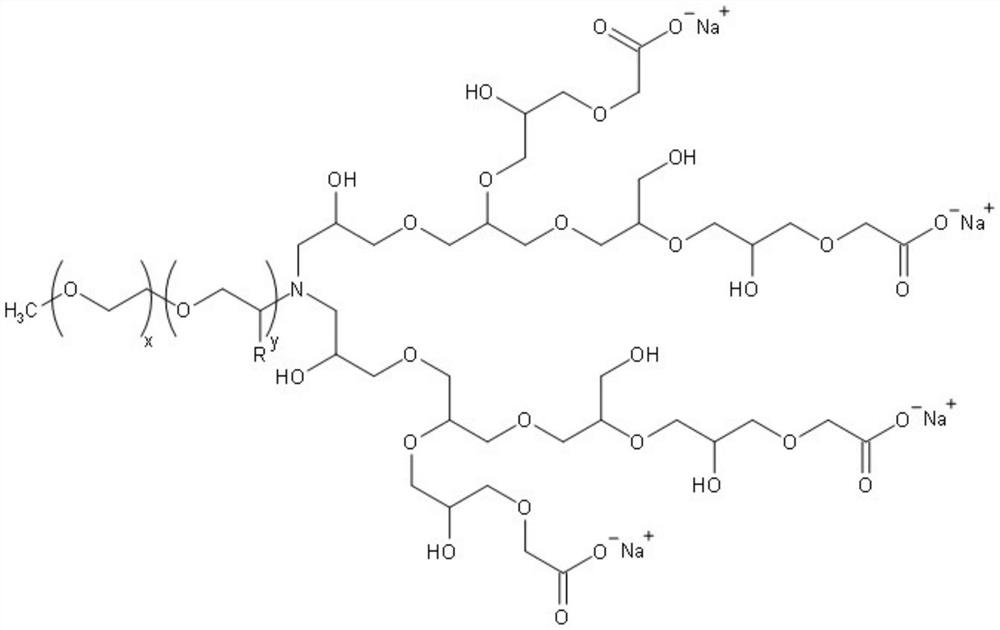

[0019] Naturally cool intermediate a to 75°C, take 21g of intermediate a and add 1.9mL of 4mol / L sodium methoxide solution under stirring, keep the temperature and stir for 5h after the addition is completed, and carry out the reaction. After the reaction is completed, the methanol is distilled off under reduced pressure. 60mL of anhydrous tetrahydrofuran and stirred to raise the temperature to 130°C, then add 180mL of glycidol in tetrahydrofuran solution dropwise within 18 hours under stirring, whe...

Embodiment 2

[0022] The embodiment of the present invention provides a preparation method of high-efficiency polycarboxylate superplasticizer, comprising:

[0023] Under nitrogen atmosphere, take 30g CH 3 [OCH 2 CH 2 ] 19 [OCH 2 CH(CH 3 )] 3 NH 2 Put it into the flask and heat it to 120°C in an oil bath. With stirring, add 4 mL of glycidyl alcohol dropwise within 30 minutes. After the addition is completed, keep stirring at the temperature for 12 hours to react to obtain intermediate a.

[0024] Naturally cool intermediate a to 70°C, take 15 g of intermediate a and add 1.4 mL of 3.7 mol / L sodium methoxide solution under stirring, keep the temperature and stir for 2 hours after the addition is completed, and react under reduced pressure to remove methanol after the reaction is completed Then add 50mL of anhydrous tetrahydrofuran and stir to heat up to 120°C, then add 160mL of glycidol in tetrahydrofuran dropwise within 15 hours under stirring, wherein the volume ratio of glycidol to ...

Embodiment 3

[0027] The embodiment of the present invention provides a preparation method of high-efficiency polycarboxylate superplasticizer, comprising:

[0028] Under nitrogen atmosphere, take 50gCH 3 [OCH 2 CH 2 ] 41 NH 2 Put it into the flask and heat it to 150°C in an oil bath. With stirring, add 9 mL of glycidyl alcohol dropwise within 1 hour. After the addition is completed, keep stirring at the temperature for 24 hours to react to obtain intermediate a.

[0029] Naturally cool intermediate a to 75°C, take 25g of intermediate a and add 2mL of 4mol / L sodium methoxide solution under stirring, keep the temperature and stir for 6h to react after the addition is completed, and remove methanol by distillation under reduced pressure after the reaction is completed, then add 80mL Anhydrous tetrahydrofuran and stirring to heat up to 150 ° C, and then under stirring, dropwise add 190 mL of tetrahydrofuran solution of glycidol within 20 hours, wherein the volume ratio of glycidol to tetra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com