Multi-pivot-element high-entropy alloy and preparation method thereof

A high-entropy alloy, multi-principal technology, applied in the field of materials, can solve the problems of low strength and poor plasticity, and achieve the effects of low cost, good plasticity and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

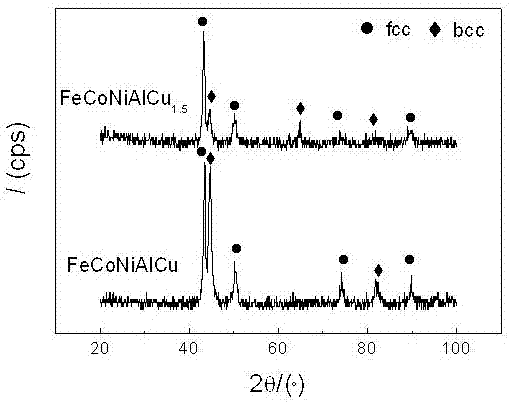

[0042] The composition of the multi-principal high-entropy alloy is FeCoNiAlCu, that is, a=1.0, b=1.0, c=1.0, d=1.0, e=1, and the specific steps are as follows:

[0043] Step 1: Put the alloy raw material in a beaker, pour low-solubility hydrochloric acid solution, remove the oxide layer on the surface, after the oxide layer is completely removed, put the raw material into a beaker filled with ethanol and place the beaker in an ultrasonic Wash in the washing machine for 10 minutes, then replace the ethanol and wash for 5 minutes, and finally dry the raw materials with a hair dryer for smelting.

[0044] Step 2: According to the molar ratio of the multi-principal high-entropy alloy, accurately weigh Fe, Co, Ni, Al and Cu raw materials with an electronic balance and mix them.

[0045] Step 3: First remove foreign matter in the furnace, and clean the copper crucible and its inner wall in the melting furnace with absolute ethanol, then turn on the circulating cooling water system,...

Embodiment 2

[0051] The composition of the multi-principal high-entropy alloy is FeCoNiAlCu 1.5 , namely a=1.0, b=1.0, c=1.0, d=1.0, e=1.5, the specific steps are as follows:

[0052] Step 1: Put the alloy raw material in a beaker, pour low-solubility hydrochloric acid solution, remove the oxide layer on the surface, after the oxide layer is completely removed, put the raw material into a beaker filled with ethanol and place the beaker in an ultrasonic Wash in the washing machine for 10 minutes, then replace the ethanol and wash for 5 minutes, and finally dry the raw materials with a hair dryer for smelting.

[0053] Step 2: According to the molar ratio of the multi-principal high-entropy alloy, accurately weigh Fe, Co, Ni, Al and Cu raw materials with an electronic balance and mix them.

[0054] Step 3: First remove foreign matter in the furnace, and clean the copper crucible and its inner wall in the melting furnace with absolute ethanol, then turn on the circulating cooling water syste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com