Assembled type prefabricated outer wallboard structure and construction method

An exterior wall panel, prefabricated technology, applied in building components, building structures, buildings, etc., can solve problems such as hidden safety hazards, large installation errors, easy deformation, etc., to strengthen the connection strength, improve the installation quality, and ensure the connection strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In this embodiment, the process requirements for the hoisting of prefabricated exterior wall panels, the production technical requirements of prefabricated exterior wall panels, the production and installation process requirements of fixed components, etc. will not be described in detail, and the embodiment of the assembled prefabricated exterior wall panel structure involved in the present invention will be focused on.

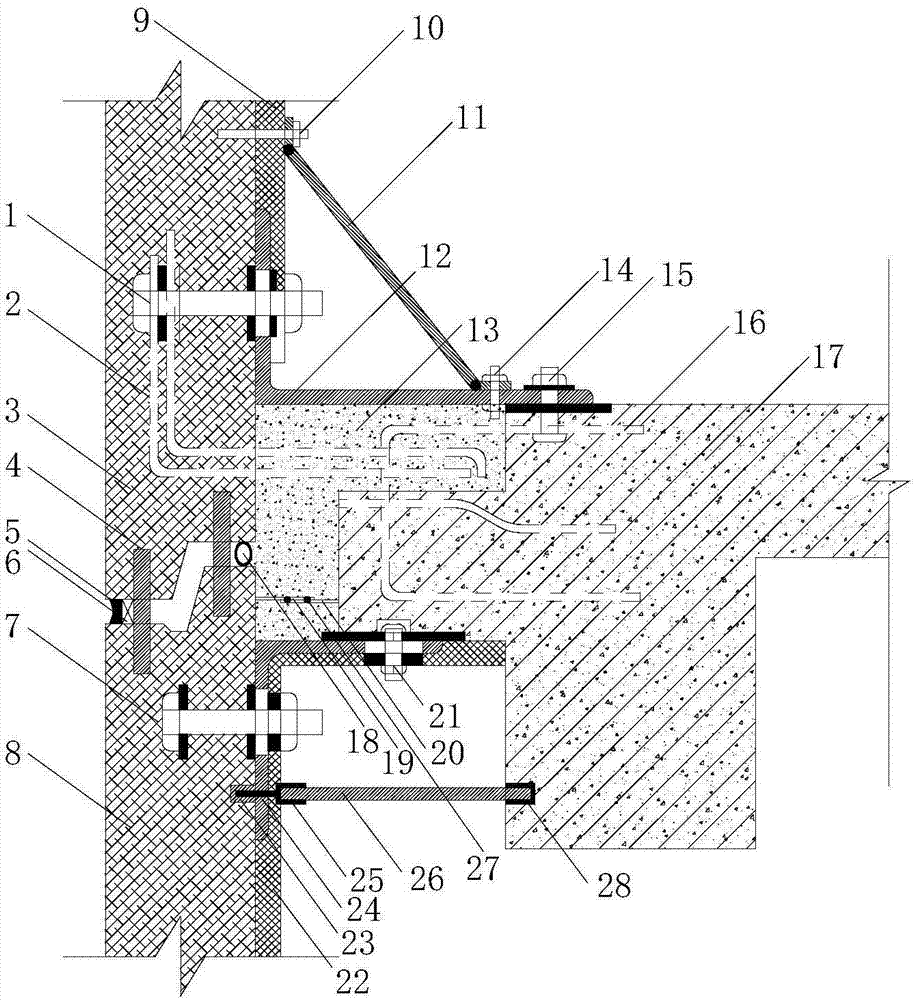

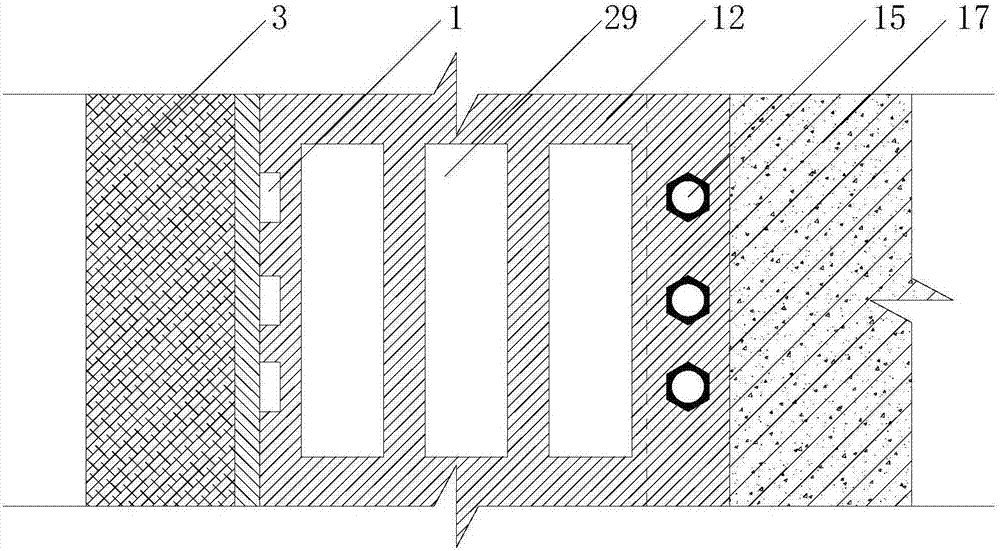

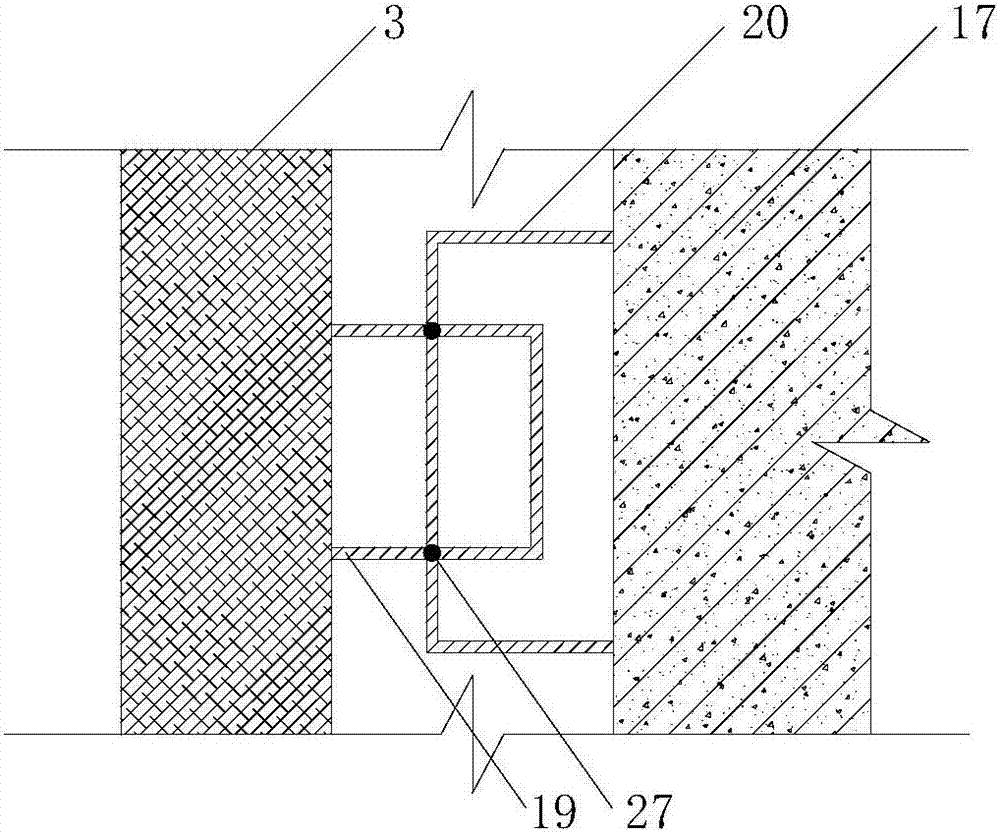

[0033] figure 1 It is a sectional view of the assembled prefabricated exterior wall panel structure of the present invention, figure 2 It is the top view of the separated angle steel in the present invention, image 3 It is the welding schematic diagram of the horizontal reserved ribs of the outer wall and the horizontal reserved ribs of the floor in the present invention.

[0034] refer to figure 1 The fabricated prefabricated exterior wall panel structure shown is mainly composed of exterior wall panels 3 of this layer, exterior wall panels 8 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com