Rotary furnace capable of simultaneously adopting hydrogen forward and reverse supply

A rotary furnace and hydrogen technology, applied in the field of reduction furnaces, can solve the problems of difficult to control the oxygen content of tungsten powder, narrow particle size composition distribution range, large particle size distribution range, etc., achieve uniform particle size composition distribution range, narrow particle size composition distribution range, The effect of large particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

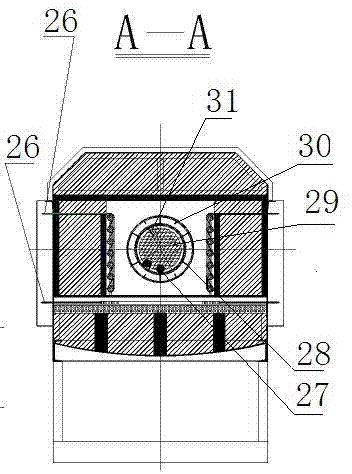

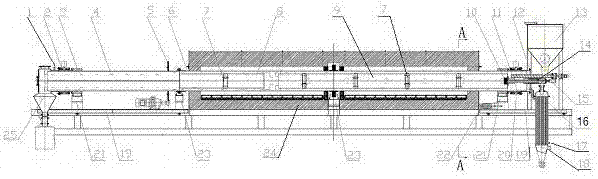

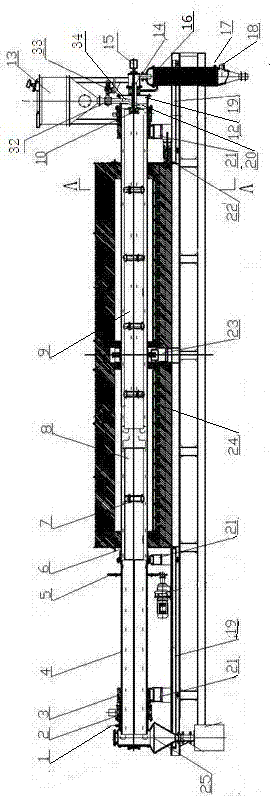

[0031] figure 1Middle: a rotary furnace that simultaneously supplies hydrogen in forward and reverse directions, including a furnace body 24 and a furnace tube 6, the furnace tube 6 passes through the furnace body 24 and is installed on the frame, and the furnace tube 6 is divided into a forward hydrogen reduction part and a reverse hydrogen reduction part; Wherein the cis-hydrogen reduction part includes a front inner furnace tube 9, a premixing chamber 20, and a heat exchanger 16. The front inner furnace tube 9 is connected and installed in the furnace tube 6 by a radial support 28, and the front inner furnace tube 9 and the furnace tube 6 are connected. A cis-hydrogen reduction zone is formed, a premixing chamber 20 is formed between the head of the front inner furnace tube 9 and the head of the furnace tube 6, and the head of the front inner furnace tube 9 is provided with an exhaust pipe 14 passing through the premixing chamber 20 to connect to the heat exchanger The hot ...

Embodiment 2

[0033] image 3 Middle: a rotary furnace that simultaneously supplies hydrogen in forward and reverse directions, including a furnace body 24 and a furnace tube 6, the furnace tube 6 passes through the furnace body 24 and is installed on the frame, and the furnace tube 6 is divided into a forward hydrogen reduction part and a reverse hydrogen reduction part; Wherein the cis-hydrogen reduction part includes a front inner furnace tube 9, a premixing chamber 20, and a heat exchanger 16. The front inner furnace tube 9 is connected and installed in the furnace tube 6 by a radial support 28, and the front inner furnace tube 9 and the furnace tube 6 are connected. A cis-hydrogen reduction zone is formed, a premixing chamber 20 is formed between the head of the front inner furnace tube 9 and the head of the furnace tube 6, and the head of the front inner furnace tube 9 is provided with an exhaust pipe 14 passing through the premixing chamber 20 to connect to the heat exchanger The hot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com