Fireworks basal body

The technology of a substrate and fireworks is applied to the substrate of fireworks. It can solve the problems of large area, many operating failures, and high equipment purchase costs, and achieve the effects of improving quantity and quality, high reliability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

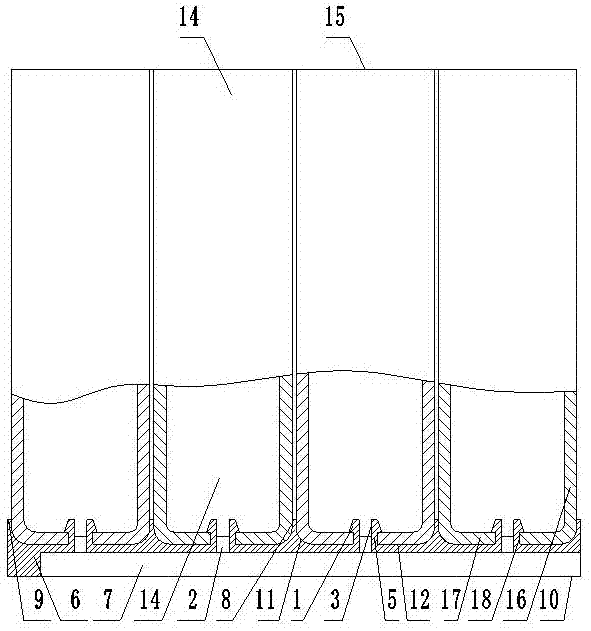

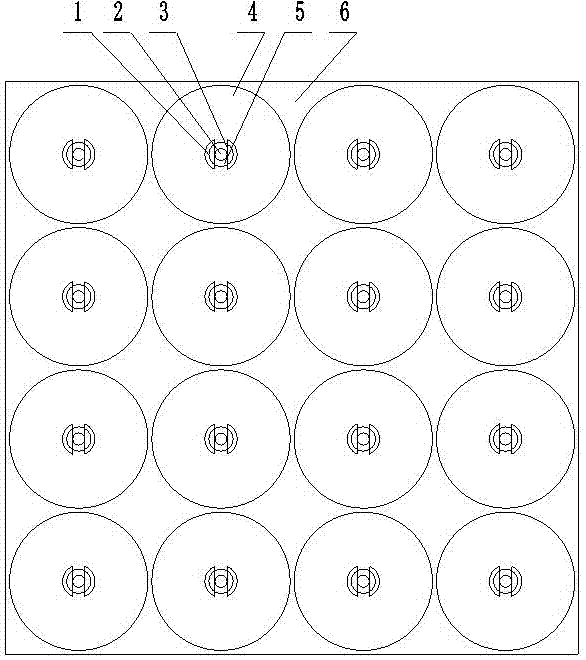

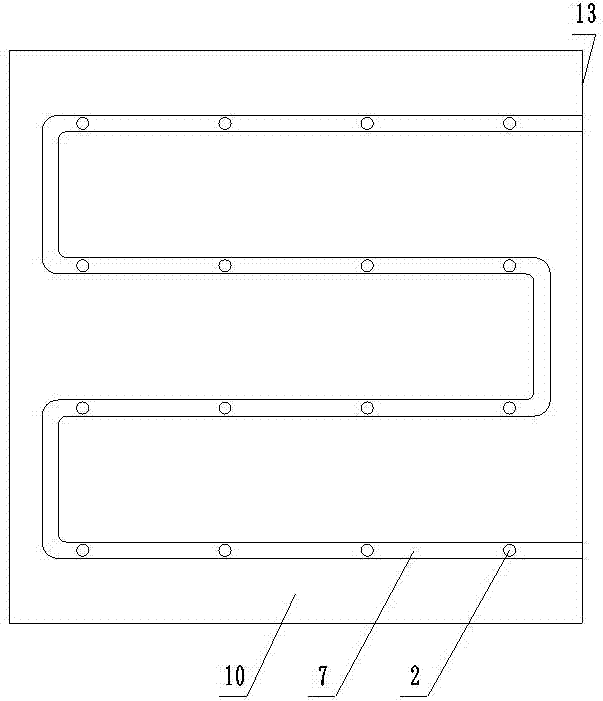

[0021] Such as figure 1 Shown in -3, a kind of fireworks substrate has stringing base 6 and cylinder 15, and cylinder 15 is inserted in the stringing base 6. There is a circular pit 4 on the top 9 of the serial lead base 6, the inner peripheral surface of the circular pit 4 is an inner cylindrical surface 8, and the junction of the inner cylindrical surface 8 and the bottom surface 12 of the circular pit 4 is a rotating arc surface 11 , There is a boss in the center of the circular pit 4, the boss top is a round platform 1, there is a hole 2 communicating with the following 10 of the string lead base 6 on the top of the boss 1, and a small groove 3 is also arranged on the boss top. The lower part of the boss is a cylinder 5. A groove 7 is arranged below the serial lead base 6, and the groove 7 communicates with the holes 2 of all bosses. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com