Device and method for measuring focal length, rear cut-off distance and resolution of non-coaxial optical system

A technology of optical system and identification rate, which is applied in the direction of measuring devices, testing optical performance, optical instrument testing, etc., can solve the problems of untrue and wrong measurement results, achieve accurate and reliable measurement data, improve economic benefits, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

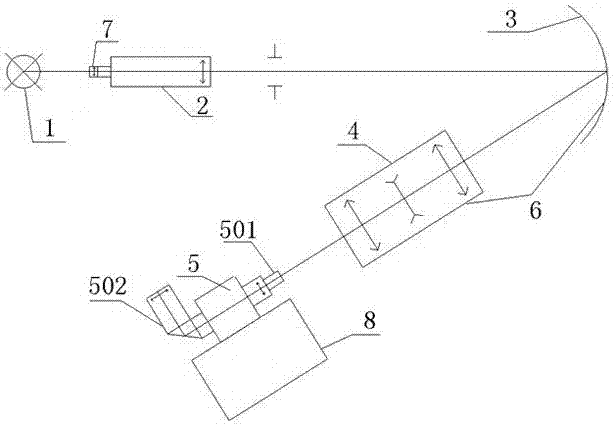

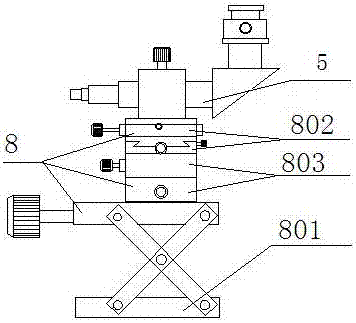

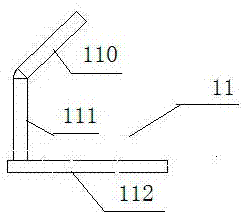

[0042] Such as figure 1As shown, a device for measuring the focal length, back intercept and discrimination rate of an incoaxial optical system includes at least a light source 1, a collimator 2, a curved mirror 3, an off-axis lens assembly 4, and a measuring microscope 5. The light source 1 is parallel to At the front end of the light pipe, there is a Poirot plate 7 or a discrimination plate 10 at the focal plane of the objective lens between the light source and the collimator to provide the object-side image surface, and the curved mirror is on the exit side of the collimator, and the object-side image irradiated by the light source Parallel light beams exit through the collimator, are received by the curved mirror, pass through the off-axis lens assembly 4 and enter the measuring microscope 5 on the imaging plane of the image side, and use the eyepiece 502 of the measuring microscope 5 for reading and measurement.

[0043] The non-coaxial optical system 6 is composed of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com