Dynamically-disturbed low-temperature rock triaxial loading and unloading rheometer and test method

A dynamic disturbance, loading and unloading technology, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, scientific instruments, etc., can solve the problems of lack, no data available for rheological characteristics and stability evaluation, etc., to achieve operation Convenience, friendly interface, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

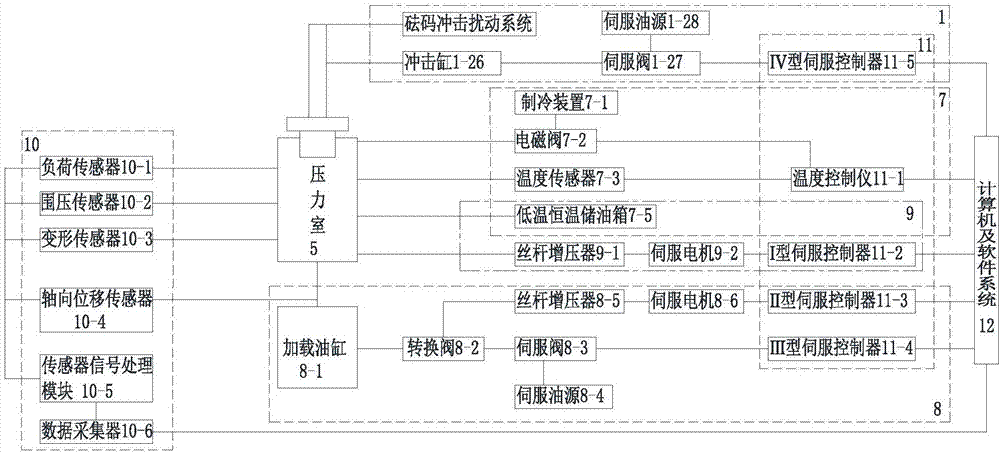

Method used

Image

Examples

Embodiment 1

[0057] The steps of applying the above-mentioned triaxial loading and unloading rheometer for dynamic perturbation low temperature rock to carry out the triaxial unloading rheological test of dynamic perturbation rock are as follows:

[0058] Step 1. Determine the test plan; assume that the test temperature is -10°C and the initial confining pressure is σ 3 =12MPa, axial pressure σ 1=60MPa, using the weight dynamic disturbance system (constant impact speed), the disturbance load is from 10kg impact weight 1-21, the free fall distance is 300mm, and the reduction motor 1-11 is adjusted to make the weight impact frequency 10 times / min , the unloading stress path is that the axial pressure is constant, the confining pressure is unloaded step by step, and the unloading level of the confining pressure is 3MPa, such as Figure 12 shown.

[0059] Step 2, sample preparation; take the processed cylindrical rock sample 13 of φ50×100mm, fully saturate it with water, put it in a low-temp...

Embodiment 2

[0066] The steps of applying the above dynamic disturbance low temperature rock triaxial loading and unloading rheometer to carry out rock dynamic disturbance low temperature triaxial loading rheological test are as follows:

[0067] Step 1, determine the test plan; assume that the test temperature is -10°C and the test confining pressure is σ 3 =8MPa, initial axial pressure σ 1 =40MPa, using the impact cylinder dynamic disturbance system (the mass of the impact rod is constant), the dynamic disturbance speed is set to 10m / s by the software, the impact frequency is set to 0.1Hz, the loading stress path is that the confining pressure remains constant, and the axial pressure increases step by step, and Axial pressure step loading level is 5MPa, such as Figure 13 shown.

[0068] Steps 2-5 are the same as steps 2-5 in the first embodiment.

[0069] Step 6, low temperature rock triaxial loading rheological test under the action of dynamic disturbance; start the impact cylinder ...

Embodiment 3

[0072] The steps of applying the above dynamic disturbance low temperature rock triaxial loading and unloading rheometer to carry out rock dynamic disturbance low temperature triaxial compression test are as follows:

[0073] Step 1, determine the test plan; assume that the test temperature is -10°C and the test confining pressure is σ 3 =8MPa, using the weight dynamic disturbance system (constant impact speed), the disturbance load is from 10kg impact weight 1-21, the free fall distance is 300mm, and the reduction motor 1-11 is adjusted to make the weight impact frequency 10 times / min .

[0074] Steps 2-5 are the same as steps 2-5 in the first embodiment.

[0075] Step 6, triaxial compression test of low-temperature rock under dynamic disturbance; start the axial pressure loading system 8 and the confining pressure loading system 9, and adjust the switching valve 8-2 so that the servo valve 8-3 communicates with the loading cylinder 8-1. At this time , the axial loading sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com