A watertight digital communication network cable for ships and a preparation method thereof

A digital communication network and watertight technology, which is applied in the direction of communication cables, cable/conductor manufacturing, submarine cables, etc., can solve the problem that the digital communication network cables for ships cannot meet the requirements of the ship's watertight system, and achieve excellent electrical performance and Mechanical properties, high degree of protection, and high impedance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the ship's watertight digital communication network cable comprises the following steps:

[0039] 1) A single round copper wire is used as the conductor 1;

[0040] 2) Extrusion equipment is used to extrude polyethylene material or polyolefin material outside the conductor 1 as the insulating layer 2, and the conductor 1 and the insulating layer 2 form an insulating core;

[0041] 3) The insulated wire cores are twisted into network wire cores by pair twisting; four pairs of network wire cores are twisted together by a cable forming machine, and the automatic and continuous glue injection process is adopted to fill the glue into the network wire cores through customized molds. Fill the gap between the core 3 and the shielding layer 5, and wrap the water-absorbing expansion tape around the cable core;

[0042] 4) Tinned copper wire is braided by a braiding machine as the armor layer 7, and a water-absorbing expansion tape is wrapped around the ...

Embodiment 1

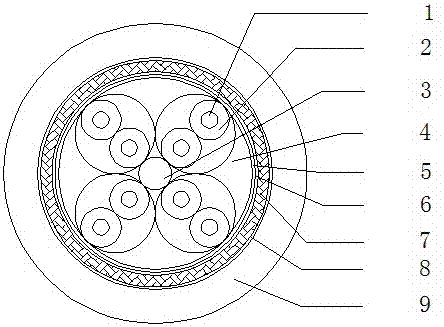

[0053]Ship watertight digital communication network cable, its structure consists of four pairs of network cores, filling core 3, sealing layer 4, shielding layer 5, A wrapping layer 6, braiding layer 7, B wrapping layer 8, sheath layer 9 composition; wherein, each pair of network cores includes two conductors 1, and each conductor 1 has an insulating layer 2 outside; four pairs of network cores are surrounded by a shielding layer 5; outside the shielding layer 5 is an A wrapping layer 6; A wrapping Outside the layer 6 is the braiding layer 7; outside the braiding layer 7 is the B-wrapping layer 8; outside the B-wrapping layer 8 is the sheath layer 9; there is a filling core 3 in the middle of the four pairs of network cores; four pairs of network cores, filling The gap formed between the core 3 and the shielding layer 5 is filled with glue as the sealing layer 4 .

[0054] The conductor 1 is a TR-type single soft round copper wire that meets the requirements of the GB / T 3953-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com