Patents

Literature

33results about How to "With cold resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

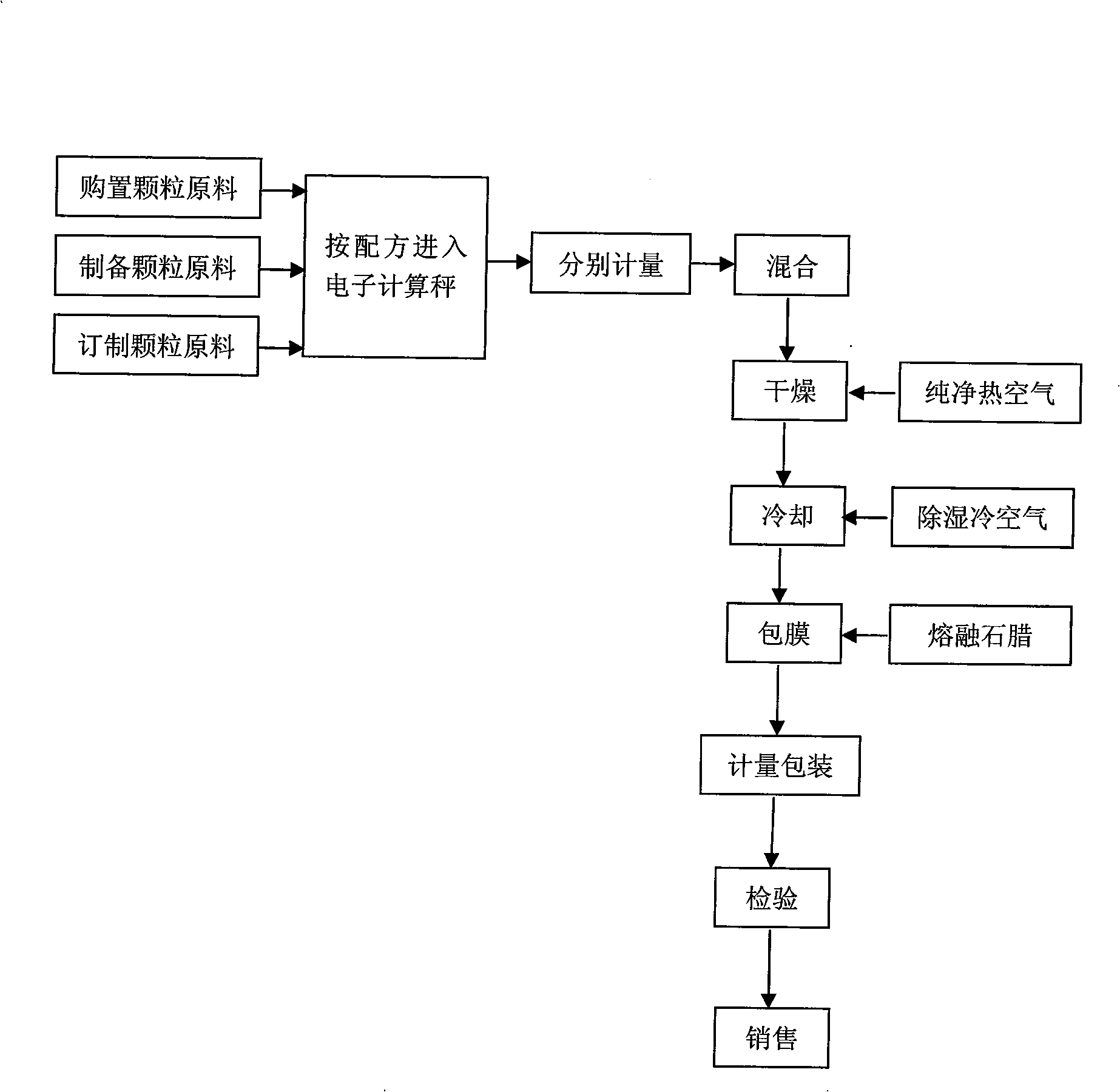

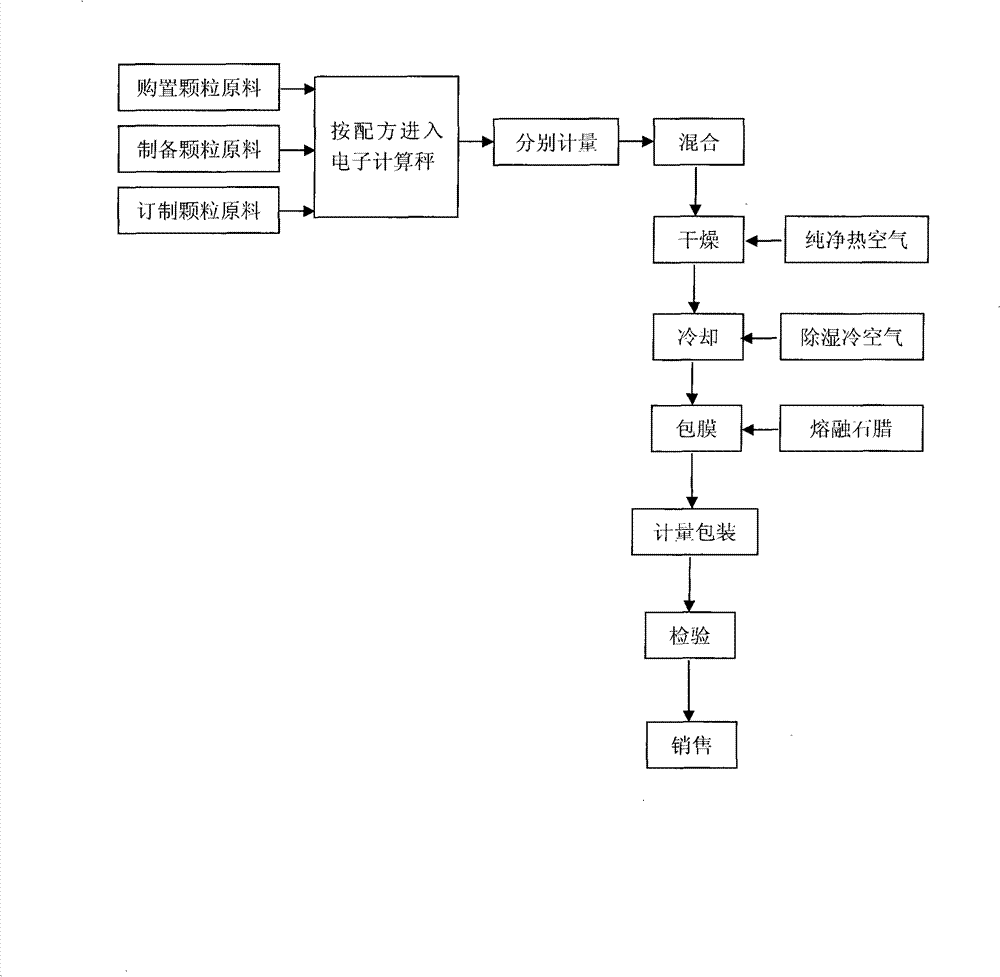

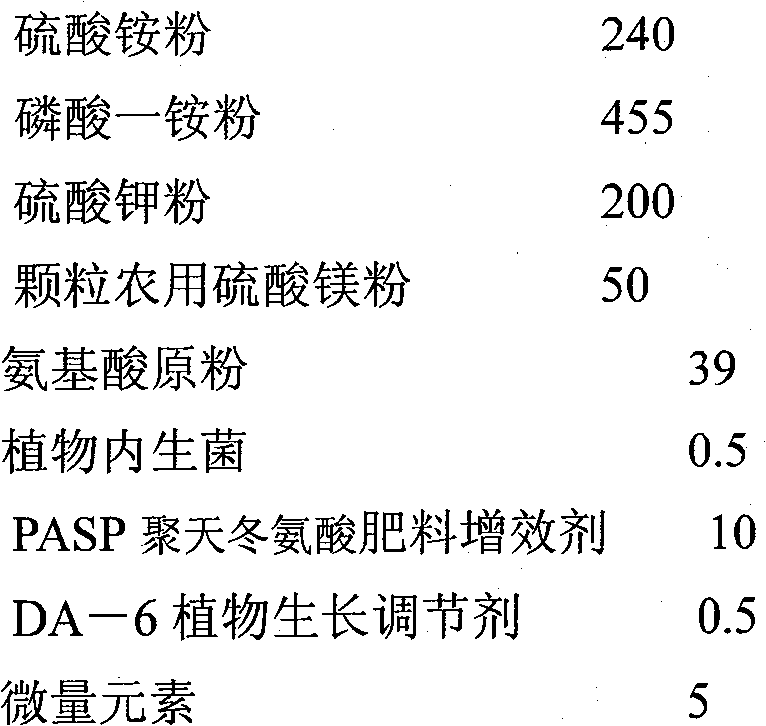

An ecological BB fertilizer

ActiveCN101514133AEfficient use ofReduce dosageAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersBiological StressEcological environment

The invention discloses an ecological BB fertilizer, relating to a mutifunctional ecological environment friendly compound fertilizer, which is formed by mixing functional urea, controllable slow release sulfurcoated urea, monoammonium phosphate, diammonium phosphate, potassium sulfate particle (or potassium chloride), agricultural magnesium sulfate particle, ammonium sulfate, bio-organic inorganic compound fertilizer, endophytic PASP fertilizer synergist DA-6, plant growth regulator and trace elements. Special ecological BB fertilizer for different plants can be prepared by soil testing formula, according to different farm crops and different soil structure. The ecological BB fertilizer can take effect for 3-120 days, the nutrition release is balanced, biological stress of the farm crop such as drought resistance, cold resistance, salt resistance, or the like can be improved. The product of the invention has great operation significance for increasing yield of grain, reducing production cost, steadily increasing grain production, keeping rural incomes growing, improving utilization rate of the fertilizer, reducing fertilizer waste, protecting ecological environment, guaranteeing farm crop quality and safety, and ensuring sustainable development of the agriculture.

Owner:苏州盛泽科技创业园发展有限公司

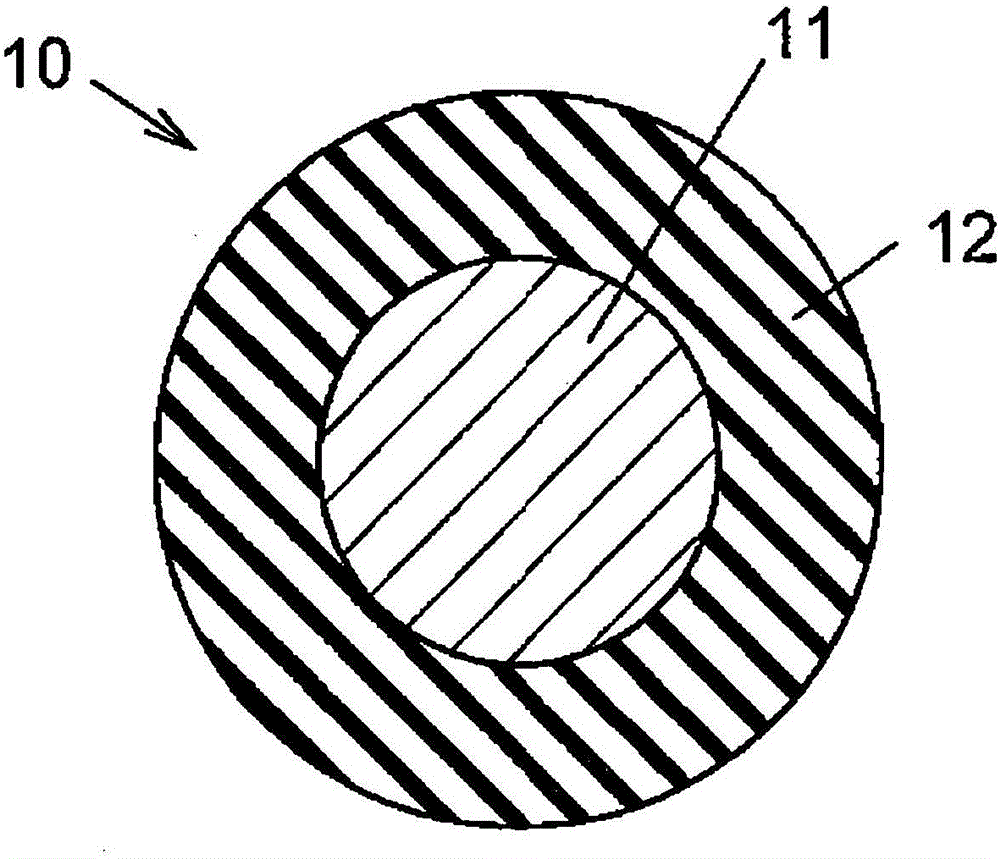

Aging-resistant silver-plastic composite pipe

An anti-aging silver-plastic composite tube takes polyethylene, polypropylene or polyvinyl chloride as the matrix material and is composed of an outer tube and an inner tube. The composition and content of the outer tube are as follows (by weight parts): low-density polyethylene (LDPE0 and / or high-density polyethylene (HDPE), polypropylene (PP) or polyvinyl chloride (PVC) 100, silver powder 0.1-10, silver ash 0.1-5, antioxidant 1010 0.5-3, wax 0.5-3 and stearic acid HST 0.5-3. The inner tube is an LDPE, PP, PVC or metal tube. The composite tube in silver-white color has the advantages of good appearance, anti-ageing effect, resistance against deformation, brittle rupture and discoloration, long service life, recyclable materials, reduced material cost, and increased product quality.

Owner:姜晓兵

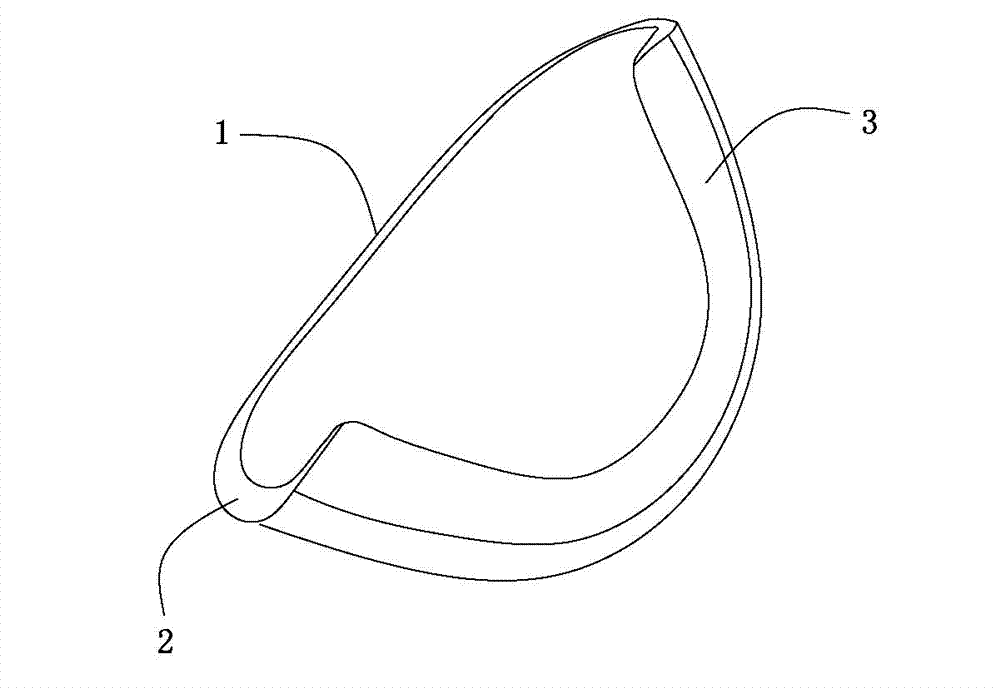

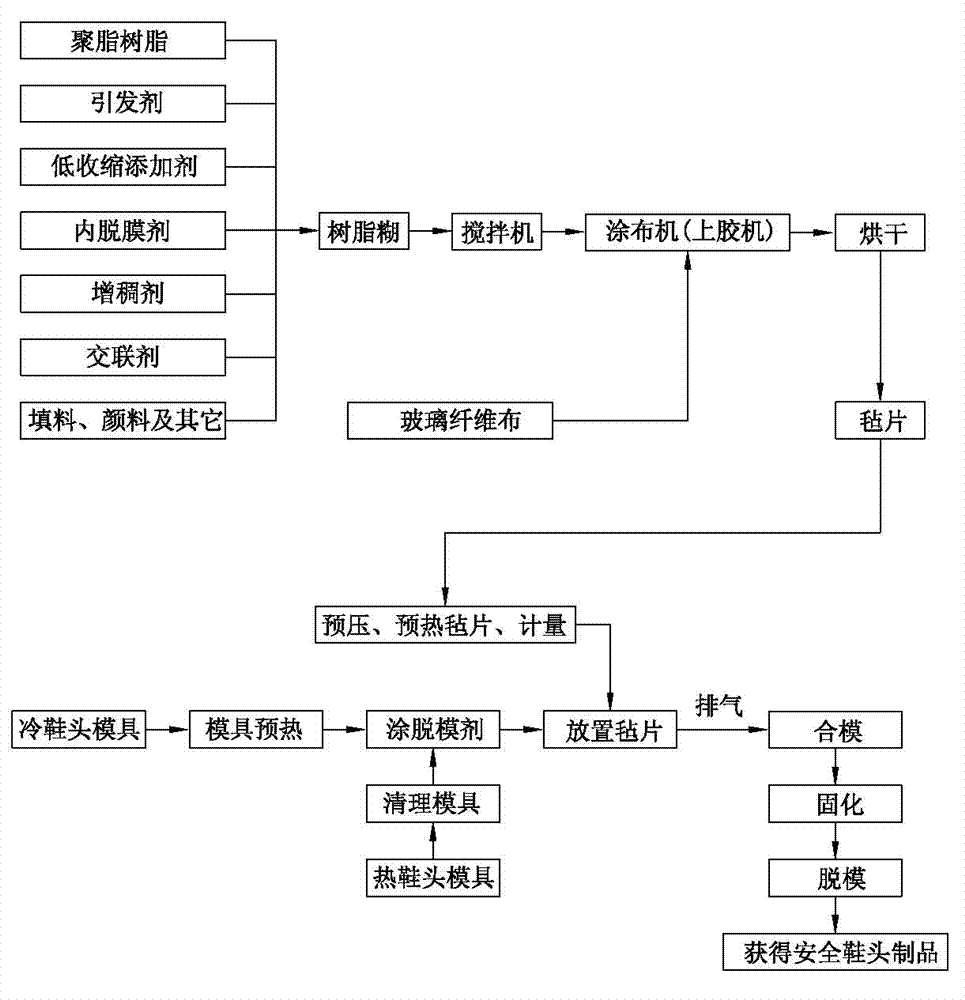

Composite material safety toe cap and manufacturing method thereof

InactiveCN103113733ADesign scienceReasonable designDomestic footwearUpperGlass fiberManufacturing technology

The invention discloses a composite material safety toe cap which is formed by bonding and pressing multiple layers of glass fiber cloth coated with resin paste, wherein the resin paste comprises polyester resin, an initiator, a low-shrink additive, an inner release agent, a thickener and a crosslinking agent; and the invention also discloses a method for manufacturing the composite material safety toe cap. The formula of the composite material safety toe cap provided by the invention is scientific and reasonable in design, has good mechanical performance and high strength, greatly enhances the impact resistance, effectively avoids the phenomena that the foot of a user kicks a foreign object or is bruised by the falling foreign object and the toes are injured, and realizes high safety; the composite material safety toe cap has the advantages of corrosion resistance, high temperature resistance, cold resistance, acid resistance and the like, and the service life is greatly prolonged; and the composite material safety toe cap can pass the International test standards such as European Union EN12568-S, Canada CSA-Z195 and the United States ASTM-F2413 and the like. The method provided by the invention has a simple manufacturing technology, is easy to realize and can quickly produce a composite material safety toe cap.

Owner:DONGGUAN HUAGU COMPOSITE MATERIAL TECH

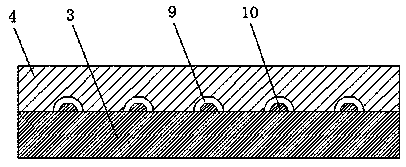

Method for processing faux suede membrana dermalis coating

ActiveCN103657981AImproved resistance to twisting and flexingIncrease elasticityPretreated surfacesPolyurea/polyurethane coatingsAdhesiveCross linker

The invention discloses a method for processing a faux suede membrana dermalis coating. The method comprises the following steps: (1) bottom layer rubber coating preparation, namely, evenly stirring 100 parts of polyurethane resin, 0.5-1 part of polyurethane thickening agent, 0.5-2 parts of melamine cross-linking agents, 4-10 parts of foam stabilizers and 1-3 parts of foaming agents and increasing the foaming size to 1-3 times, (2) facial layer rubber coating preparation, namely, evenly stirring 100 parts of coldness-resistant lightless coating adhesive, 5-10 parts of amidogen modified polysiloxane, 0.5-2 parts of cross-linking agents and color paste, (3) adopting a dry method to coat directly, increasing the dry weight of the bottom layer rubber coating by 5-8g / m2, using a planishing mill for calendaring, and increasing the dry weight of the facial layer rubber coating by 7-10g / m2. The method is simple in technology and feasible, improves the distortion and bending resistance, elasticity and softness of fabric, improves dry-wet friction firmness, wear-resisting performance and coldness resistance of the fabric, and does not influence in index of the fabric.

Owner:DANDONG UNIK TEXTILE

Cold-resistant cable with flexible protective layer

InactiveCN104164025AReduce harmHigh temperature resistancePlastic/resin/waxes insulatorsEngineeringChlorinated paraffins

The invention discloses a cold-resistant cable with a flexible protective layer. The cable is characterized by comprising the following raw materials in parts by weight: 80-120 parts of PVC (polyvinyl chloride) resin SG-2, 20-40 parts of TOTM (trioctyl trimellitate), 3-5 parts of epoxidized soybean oil, 6-10 parts of 70 chlorinated paraffin, 5-7 parts of antimony oxide, 0.3-0.7 part of antioxidant, 8-12 parts of calcined china clay, 3-7 parts of activated calcium carbonate, 5-9 parts of calcium-zinc compound stabilizer, 0.3-0.7 part of UV-531 and 20-40 parts of DOS (dioctyl sebacate). The cable has the beneficial effects that the cable has high temperature and cold resistance, is environment-friendly and practicable and can avoid open fire burning in the process of approaching fire sources; flames only spread in a limited range; residual flames or residue burning fire can be extinguished by self in a limited time; the outer protective layer of the cable can only become flexible because of approaching the fire sources and can not catch fire, thus protecting all kinds of other equipment and avoiding greater losses; in the process, the environment-friendly flame-retardant cable can not generate smoke or is low in smoke and can not generate plenty of heavy black smoke as ordinary electric wires, thus minimizing harms to human bodies.

Owner:郭良来

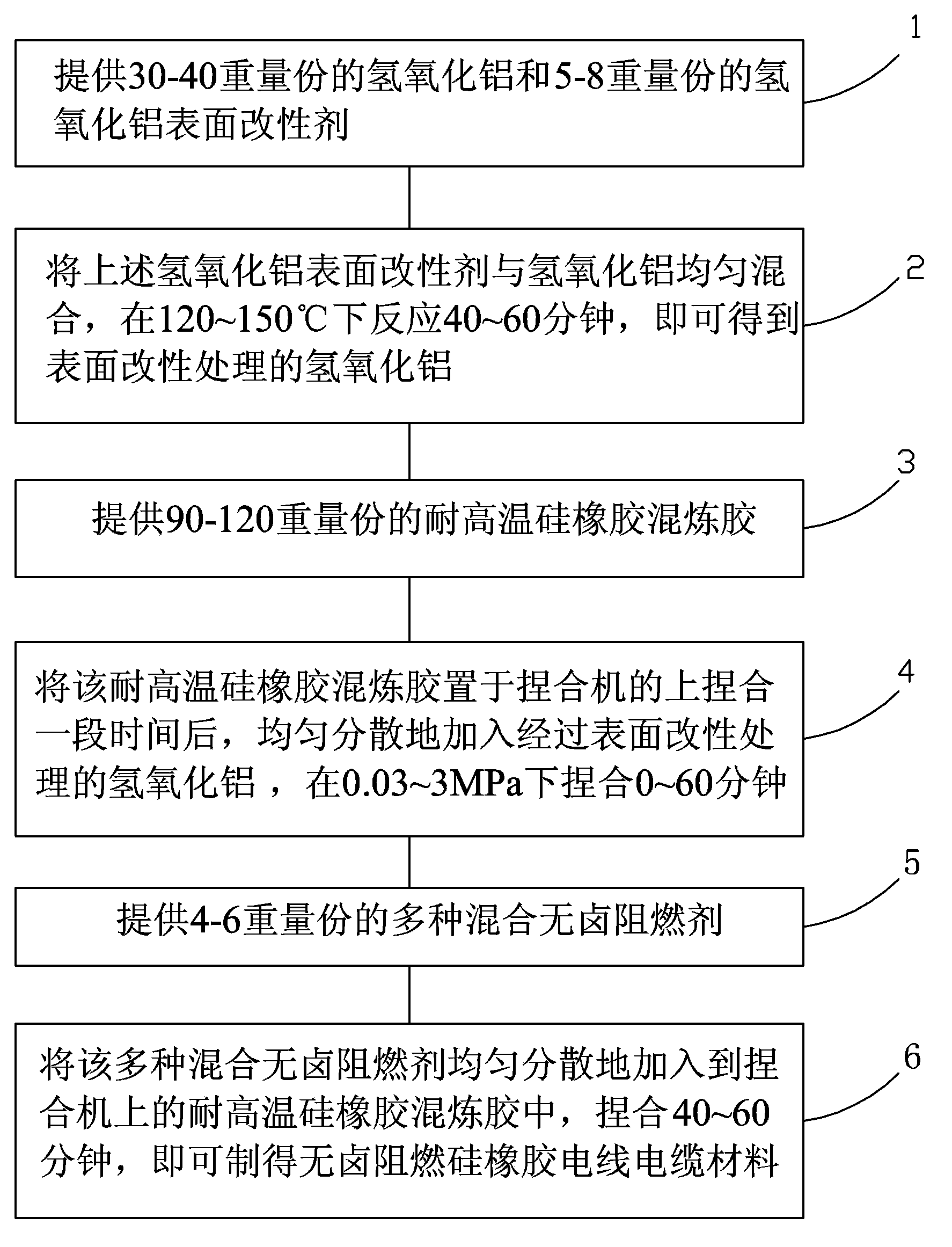

Halogen-free flame-retardant silicone rubber wire and cable material and preparation method thereof

InactiveCN103665883AHeat radiation resistantSimple processRubber insulatorsPolymer scienceAging resistance

The invention provides a halogen-free flame-retardant silicone rubber wire and cable material and a preparation method thereof. The halogen-free flame-retardant silicone rubber wire and cable material comprises the following components in parts by weight: 30-40 parts of aluminum hydroxide, 5-8 parts of aluminum hydroxide surface modifier, 4-6 parts of a mixture of multiple halogen-free flame retardants and 90-120 parts of high-temperature-resistant silicone rubber compound, wherein the mixture of multiple halogen-free flame retardants contains no aluminum hydroxide. The halogen-free flame-retardant silicone rubber wire and cable material has excellent flame retardance and excellent insulativity, mechanical property, aging resistance and environmental protection property; and the preparation method of the halogen-free flame-retardant silicone rubber wire and cable material is simple in process, easy to operate, high in production efficiency and low in cost.

Owner:东莞新东方科技有限公司

Cold-resistant oil-resistant flame-retardant polyvinyl chloride cable material without pungent smell and preparation method of cold-resistant oil-resistant flame-retardant polyvinyl chloride cable material without pungent smell

InactiveCN106280130ANo pollution in the processCold resistance noInsulated cablesInsulated conductorsPlasticizerPolyvinyl chloride

The invention discloses a cold-resistant oil-resistant flame-retardant polyvinyl chloride cable material without pungent smell. The cold-resistant oil-resistant flame-retardant polyvinyl chloride cable material without pungent smell comprises, by mass, 20-25 parts of resin powder, 15-20 parts of plasticizer, 5-10 parts of lubricant, 10-15 parts of carbon black, 8-13 parts of stabilizer, 9-14 parts of polyethylene glycol, 17-22 parts of flame retardant, 7-12 parts of Elvaloy and 16-21 parts of nitrile butadiene rubber powder. The cold-resistant oil-resistant flame-retardant polyvinyl chloride cable material without pungent smell and a preparation method have the advantages that since polyethylene glycol is added into a preparation process, the intrinsic pungent smell of the materials can be eliminated; the plasticizer, the Elvaloy and the nitrile butadiene rubber powder are added into the preparation process, so that the prepared material is resistant to cold and oil; the nitrile butadiene rubber powder is capable of assisting the Elvaloy in preventing the plasticizer from separating out, and the Elvaloy is a non-migrating terpolymer and endows a PVC (polyvinyl chloride) polymer with high durability and high heat stability.

Owner:JIANGSU LINRY NEW MSTAR TECH

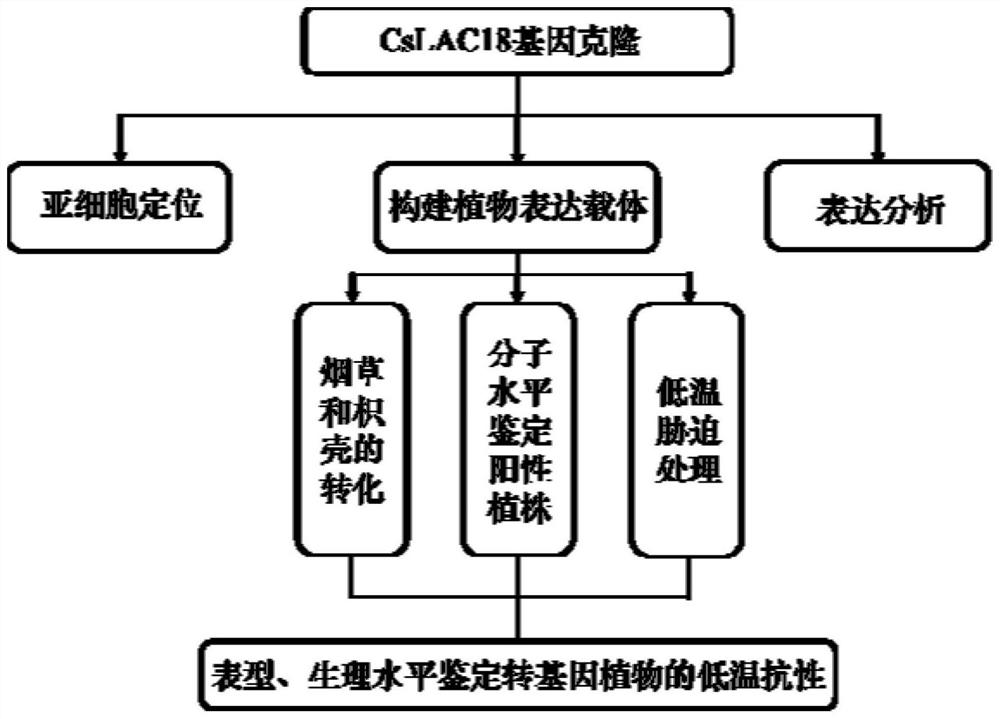

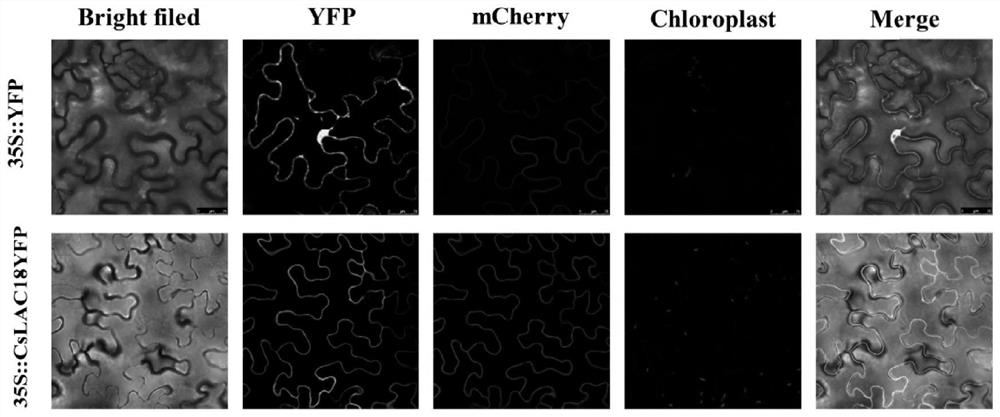

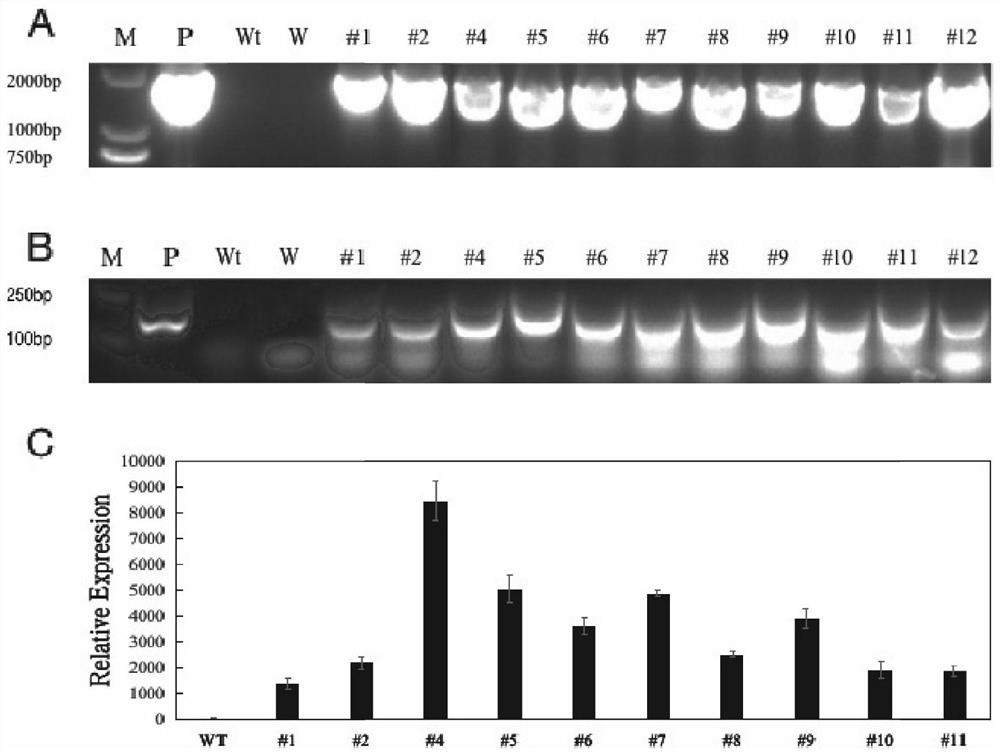

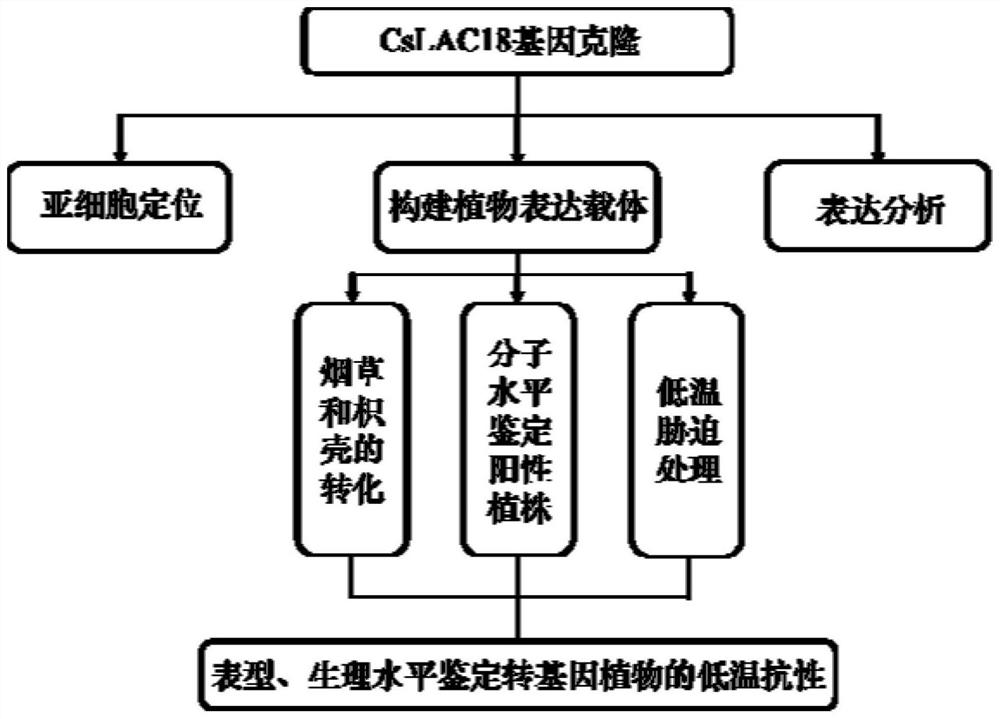

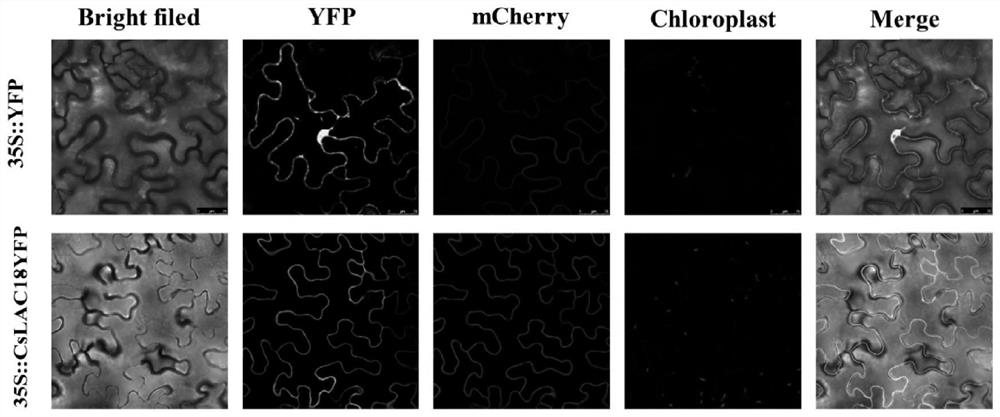

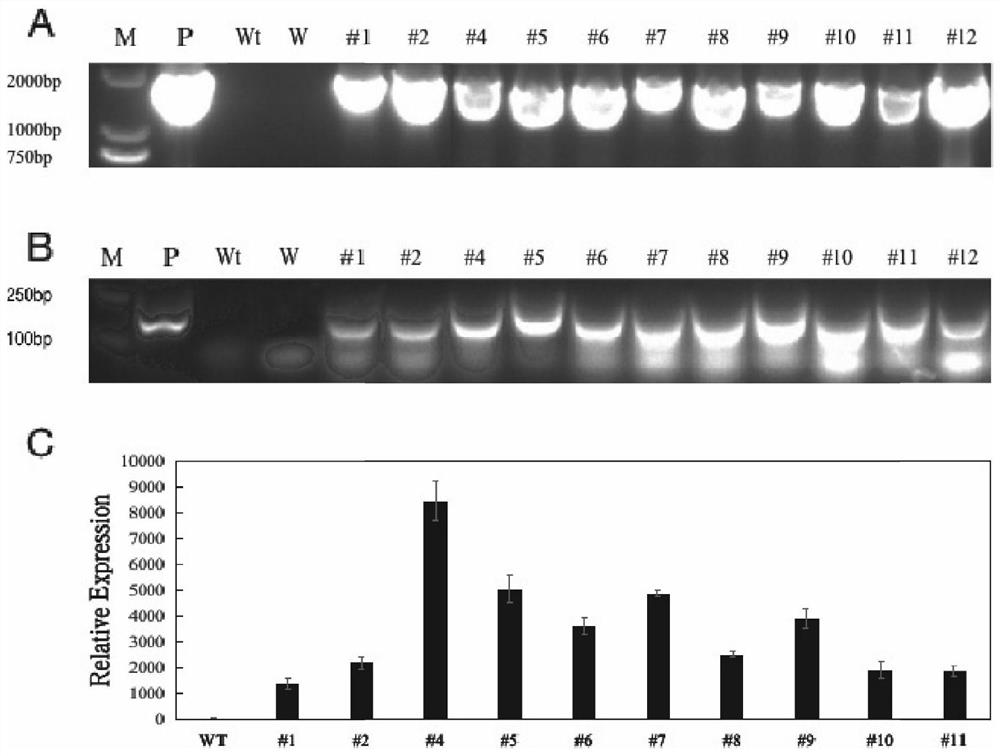

Cold-resistant gene CsLAC18 of sweet oranges and application of cold-resistant gene CsLAC18

ActiveCN111961680APossesses the function of positively regulating cold resistanceWith cold resistanceOxidoreductasesFermentationNicotiana tabacumResistant genes

The invention provides a cold-resistant functional gene CsLac18 separated and cloned from sweet oranges; the nucleotide sequence of the cold-resistant functional gene CsLac18 is shown as SEQ ID NO.1,and the corresponding amino acid sequence of the cold-resistant functional gene CsLac18 is shown as SEQ ID NO.2. The gene CsLac18 is introduced into tobacco and fructus aurantii for functional verification, and it is found that the cold resistance of the obtained transgenic overexpression plant is obviously improved, and the cold resistance of the transgenic silent expression plant is obviously reduced. Important gene resources are provided for plant cold-resistant gene engineering, and the cold resistance of plants can be improved.

Owner:YANGZHOU UNIV

Silicon/fluoroether/fluorosilicone composite rubber material and preparation method thereof

InactiveCN107828165AImprove stabilityHigh temperature resistanceRubber material(Hydroxyethyl)methacrylate

The invention provides a silicon / fluoroether / fluorosilicone composite rubber material. The silicon / fluoroether / fluorosilicone composite rubber material is formed by compounding silicon rubber, fluoroether rubber and fluorosilicone rubber according to a mass ratio 1:(2-5):(2-4), wherein the silicon rubber is fluorine-containing ionic liquid-modified graphene-modified silicone rubber, the fluoroether rubber is fluorosilane-modified graphene-filled fluoroether rubber, and the fluorosilicone rubber is hydroxyethyl methacrylate-modified graphene-filled fluorosilicone rubber. On one hand, the silicone rubber, the fluoroether rubber and the fluorosilicone rubber with excellent properties are compounded so as to integrate the advantages of individual rubber products and overcome the correspondingdefects of single products; the obtained composite rubber integrates the advantages of high temperature resistance, low temperature resistance, aging resistance and good stability of the silicone rubber, has the characteristics of heat resistance, cold resistance, solvent resistance and chemical resistance of the fluorosilicone rubber, and has the characteristics of high temperature resistance, strongly corrosive medium resistance, superstability of the fluoroether rubber, and is very excellent in properties and wide in industrial application prospect.

Owner:张文平

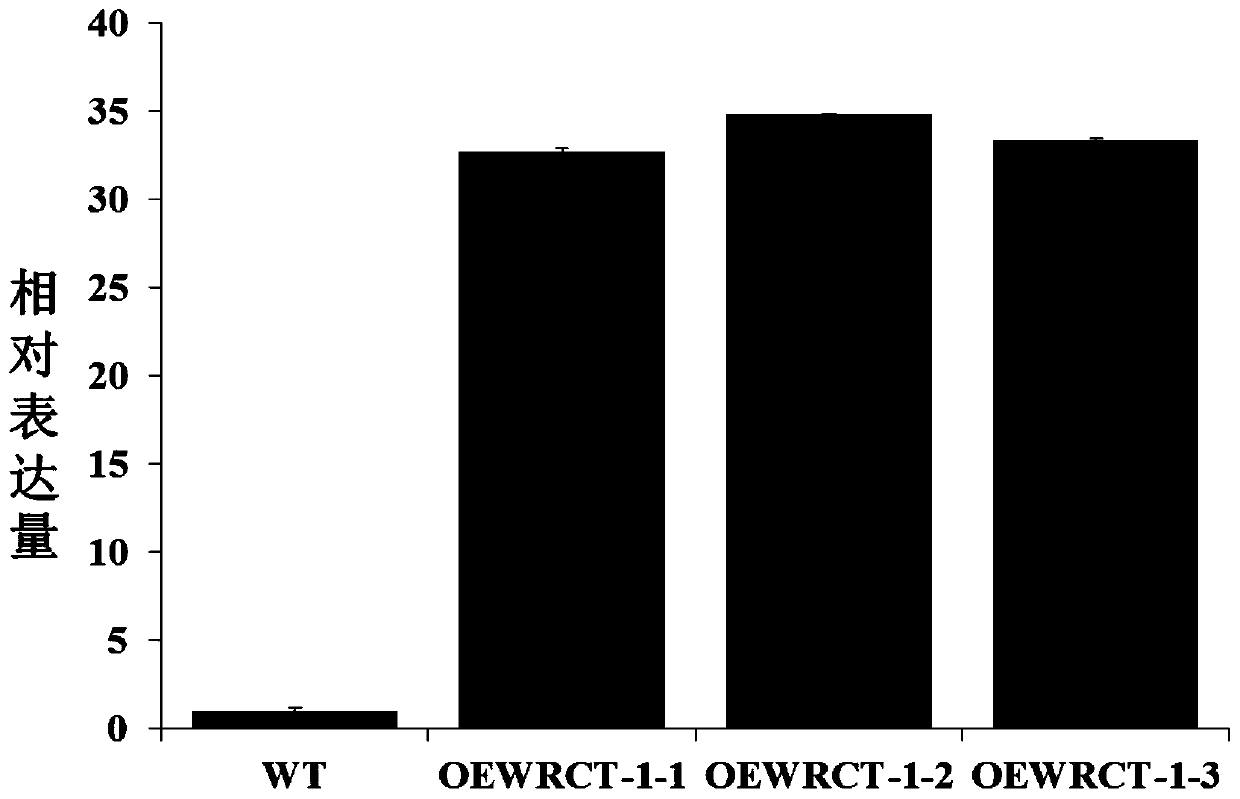

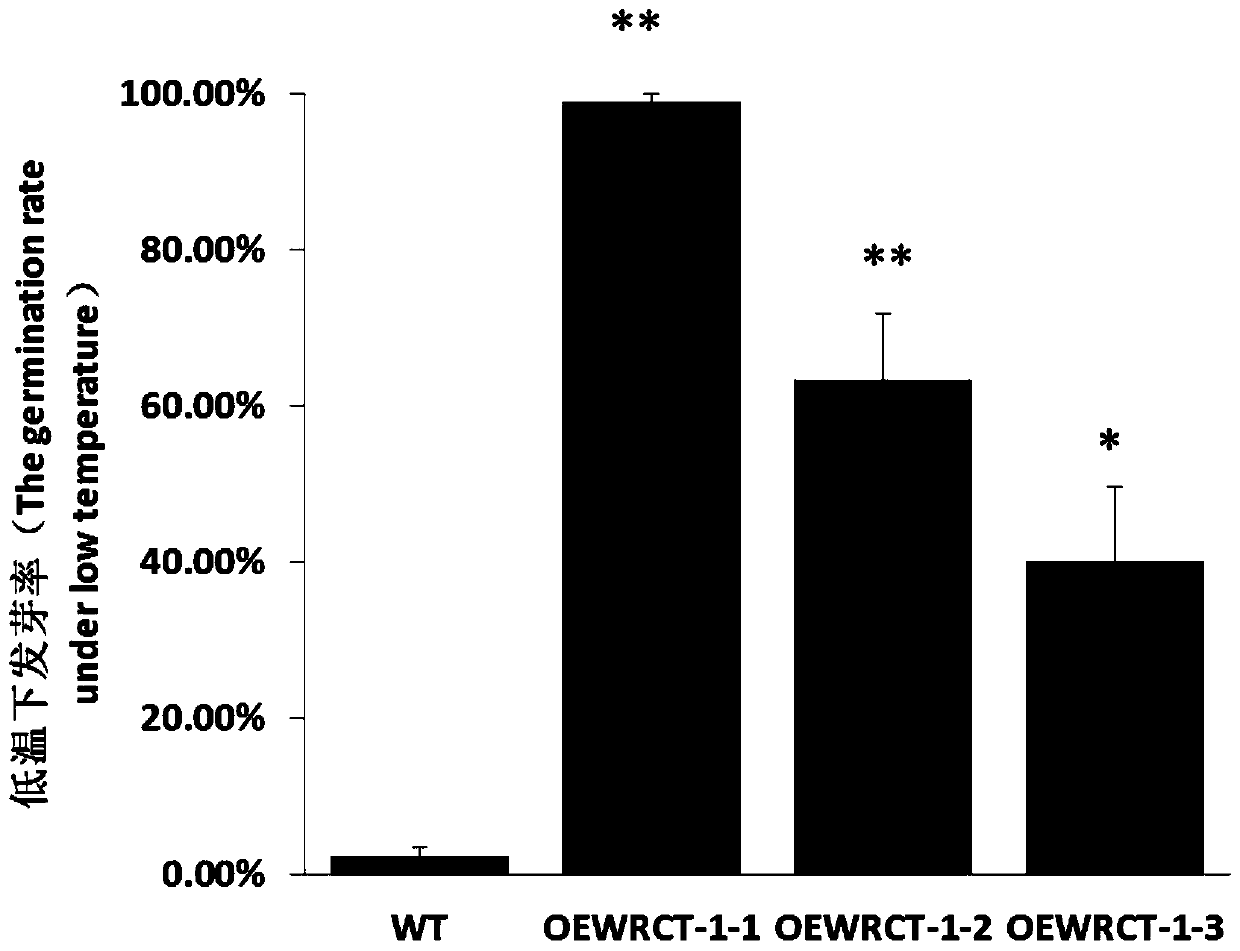

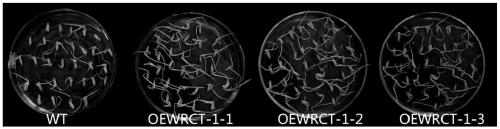

Cold-tolerant correlative coding gene of oryza rufipogon in bud stage, and applications thereof

The invention discloses a cold-tolerant correlative coding gene of oryza rufipogon in a bud stage. The name of the cold-tolerant correlative coding gene is WRCT-1. Applications of the cold-tolerant correlative coding gene WRCT-1 in the regulation of the germination rate of paddy rice under low temperature, or the applications in the cultivation of cold-tolerant transgenic paddy rice in the bud stage are also disclosed. The cold-tolerant correlative coding gene WRCT-1 is identified for the first time; the cold-tolerant correlative coding gene WRCT-1 has cold-tolerant characteristics in the budstage under conditions of enhanced function or increased expression; and the important effects of cold-tolerant correlative coding gene protein or the protein thereof on controlling the cold toleranceof the paddy rice in the bud stage can be proved.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

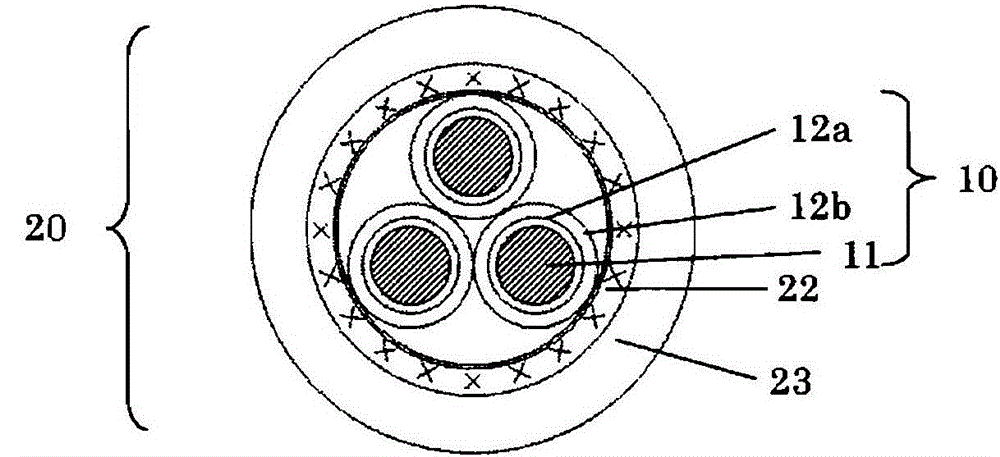

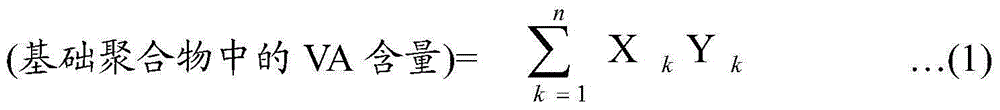

Insulated wire and cable

InactiveCN105070355APrevent scumWith low temperature characteristicsInsulated cablesInsulated conductorsElectrical conductorEngineering

The invention provides a insulated wire and cable. The invention aims to provide insulated wire and cable with low temperature properties, flexibility, oil resistance, cold resistance, fire retardancy and mechanical properties. The insulated wire has a conductor and insulated layer formed peripherally around the conductor. The insulated layer is made of a non-halogen flame-retardant resin composition. Metal hydroxide is added in a base polymer containing an ethylene-vinyl acetate copolymer; the metal hydroxide includes magnesium hydroxide; the base polymer has a vinyl acetate content of 20 mass% or higher to below 50 mass%. The insulated layer has advantages of fire retardancy, mechanical properties,low temperature properties and cold resistance.

Owner:HITACHI METALS LTD

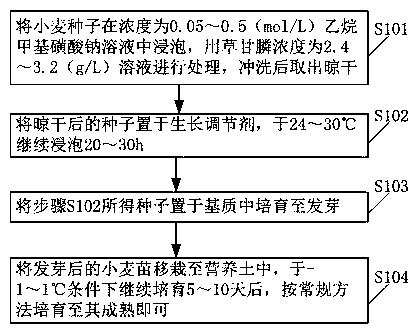

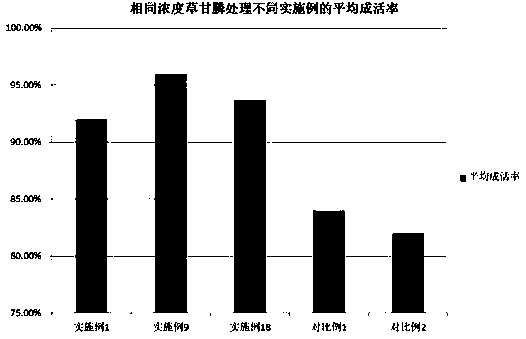

Cultivation method for improving wheat stress resistance

InactiveCN111226773AGuaranteed germination rateGuaranteed uniformityPlant growth regulatorsBiocideGlyphosateCold resistance

The invention discloses a cultivation method for improving the stress resistance of wheat, which comprises the following steps: S101, soaking wheat seeds in a sodium ethanemethanesulfonate solution with the concentration of 0.05-0.5 (mol / L), treating with a glyphosate solution with the concentration of 2.4-3.2 (g / L), washing, taking out, and airing; S102, placing the aired seeds in a growth regulator, and continuously soaking the seeds at 24-30 DEG C for 20-30 hours; S103, placing the seeds obtained in the step S102 in a matrix to be cultured until germination; and S104, transplanting the germinated wheat seedlings into nutrient soil, continuously culturing for 5-10 days at the temperature of -1-1 DEG C, and culturing according to a conventional method until the germinated wheat seedlingsare mature. According to the method disclosed by the invention, the seeds have certain cold resistance, so that a wheat plant with stress resistance is obtained.

Owner:WHEAT RES INST OF AGRI SCI

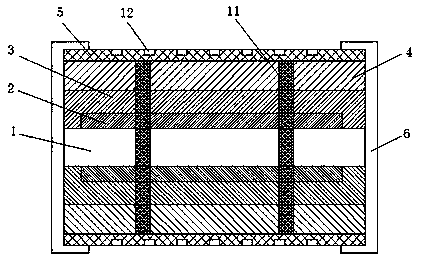

Novel anti-pressure cold-resistant conveyor belt

InactiveCN108790328ASimple structureReasonable designConveyorsGlass/slag layered productsGlass fiberWear resistant

The invention relates to a novel anti-pressure cold-resistant conveyor belt. The novel anti-pressure cold-resistant conveyor belt comprises a main body, buffer layers are connected with the outer surface of the main body, steel wire skeleton layers are arranged on the outer surfaces of the buffer layers, glass fiber layers are arranged on the outer surfaces of the steel wire skeleton layers, wear-resistant layers are arranged on the outer surfaces of the glass fiber layers, edge covers are arranged on the two sides of the main body, the edge covers are connected with the main body, the steel wire skeleton layers, the glass fiber layers and the wear-resistant layers separately, the buffer layers comprise rubber main bodies, atmospheric pressure cavities are formed in the rubber main bodies,air cushions are symmetrically arranged on the tops and bottoms of the atmospheric pressure cavities, concave holes are formed in the bottoms of the glass fiber layers, bulges are arranged on the tops of the steel wire skeleton layers, the bulges are arranged in the concave holes, and a fixing rod is arranged on the main body. The novel anti-pressure cold-resistant conveyor belt is stable in structure and has the capability of working in a low-temperature environment, and the layers are closely connected and not prone to be detached, so that the stability of the conveyor belt is improved.

Owner:YANGZHOU BAODA RUBBER & PLASTIC PROD

An ecological BB fertilizer

ActiveCN101514133BEfficient use ofReduce dosageAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersBiological StressEcological environment

The invention discloses an ecological BB fertilizer, relating to a mutifunctional ecological environment friendly compound fertilizer, which is formed by mixing functional urea, controllable slow release sulfurcoated urea, monoammonium phosphate, diammonium phosphate, potassium sulfate particle (or potassium chloride), agricultural magnesium sulfate particle, ammonium sulfate, bio-organic inorganic compound fertilizer, endophytic PASP fertilizer synergist DA-6, plant growth regulator and trace elements. Special ecological BB fertilizer for different plants can be prepared by soil testing formula, according to different farm crops and different soil structure. The ecological BB fertilizer can take effect for 3-120 days, the nutrition release is balanced, biological stress of the farm crop such as drought resistance, cold resistance, salt resistance, or the like can be improved. The product of the invention has great operation significance for increasing yield of grain, reducing production cost, steadily increasing grain production, keeping rural incomes growing, improving utilization rate of the fertilizer, reducing fertilizer waste, protecting ecological environment, guaranteeing farm crop quality and safety, and ensuring sustainable development of the agriculture.

Owner:苏州盛泽科技创业园发展有限公司

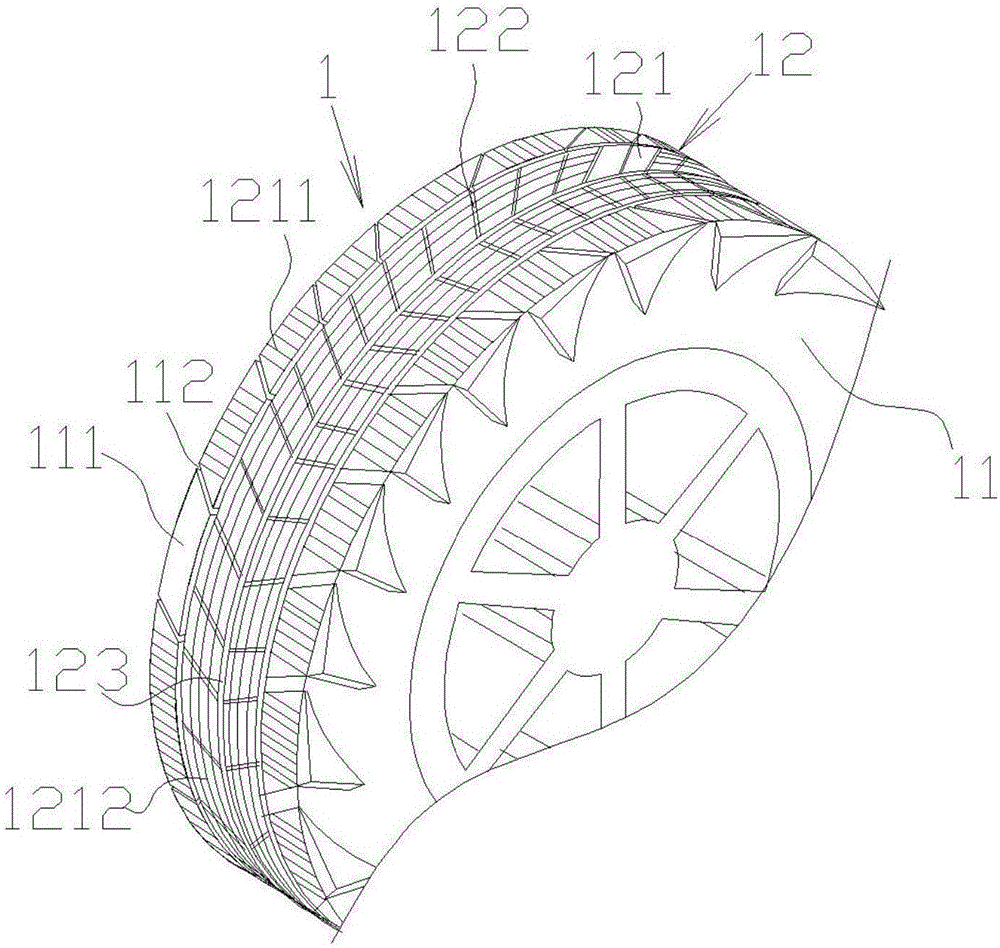

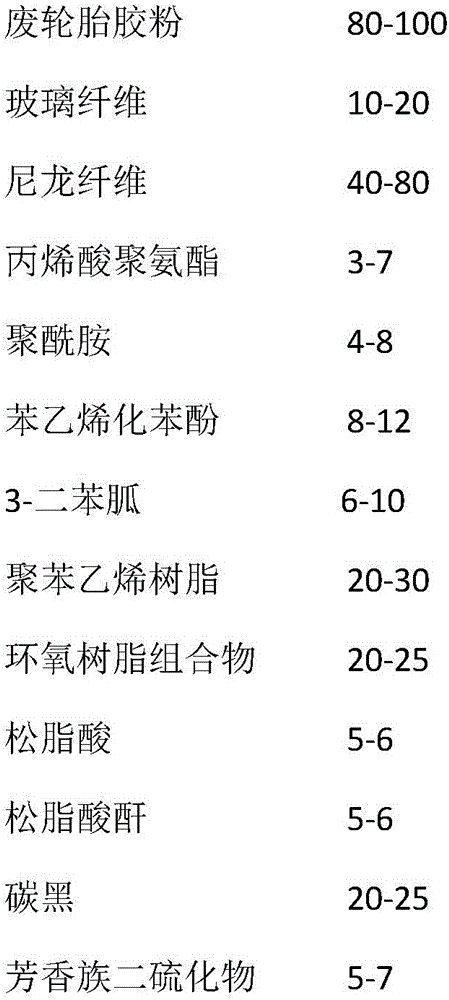

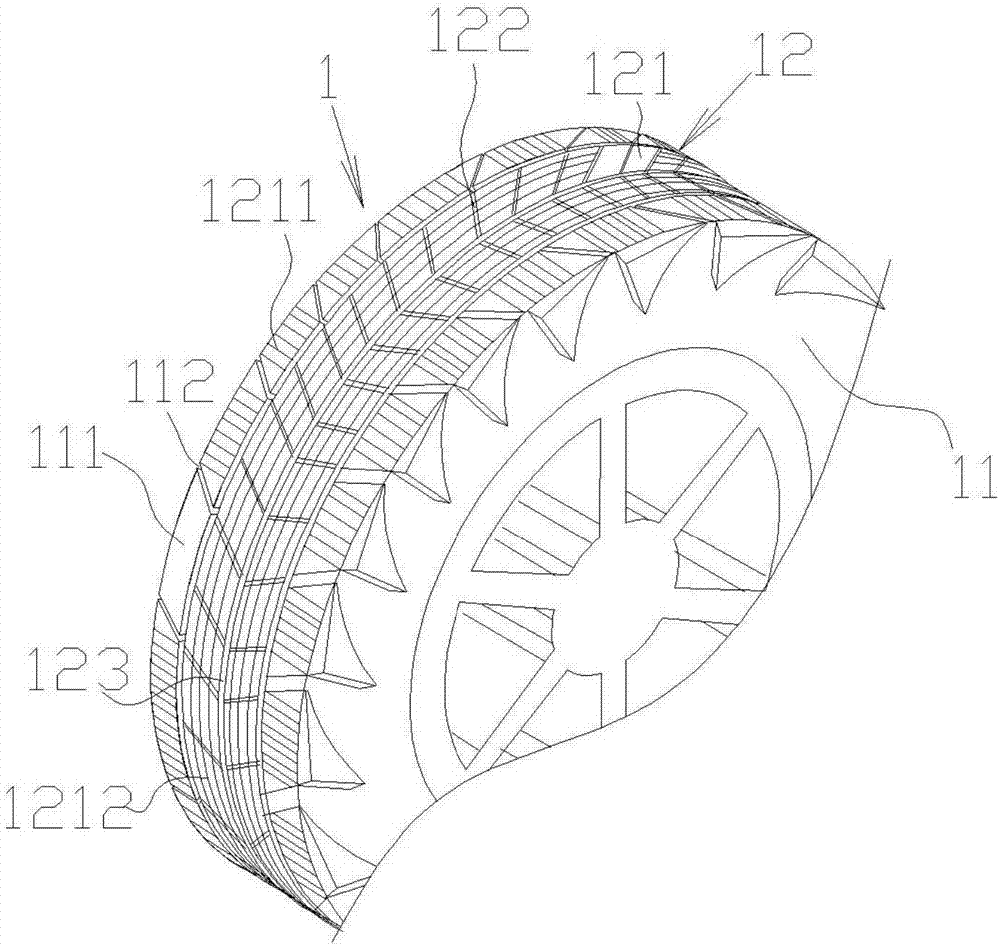

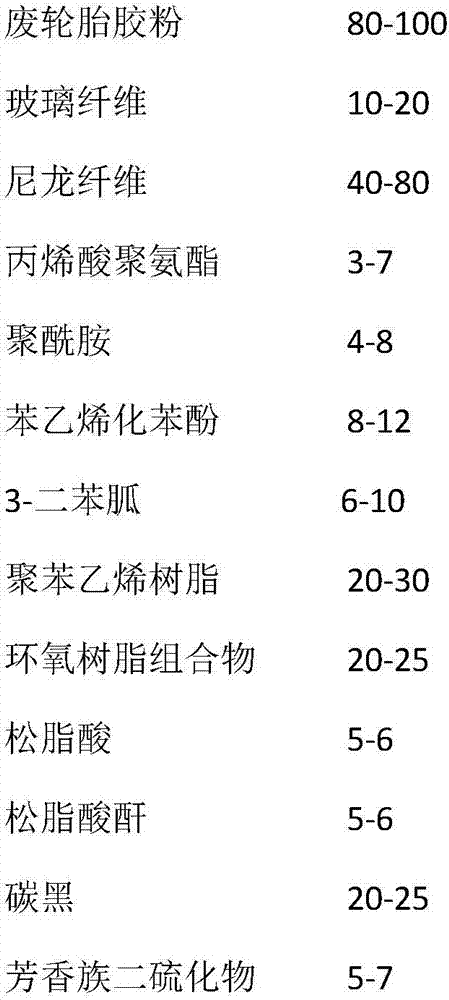

Reclaimed rubber and tire made thereof

The invention provides reclaimed rubber and a tire made thereof. The reclaimed rubber comprises the following materials: waste tire rubber powder, glass fibers, nylon fibers, acrylic polyurethane, polyamide, styrenated phenol, 3-diphenylguanidine, polystyrene resin, an epoxy resin composition, abietic acid, rosin anhydride, carbon black, aromatic disulfide and zinc salt. The tire made of the reclaimed rubber comprises a tire body; the tire body comprises two tire side surfaces and a tire peripheral surface positioned between the two tire side surfaces; air guide blocks are distributed on at least one tire side surface, and an air guide groove is formed between the two adjacent air guide blocks; multi-ring brake pattern blocks are arranged on the tire peripheral surface and are symmetrically arranged about a center line of the tire peripheral surface, a flow guide groove is formed between the two adjacent brake pattern blocks on the same ring, and the air guide groove is connected with the flow guide groove. The reclaimed rubber provided by the invention is high in mechanical strength, strong in elasticity, aging-resistant, cold-resistant, high temperature-resistant and strong in braking performance and driving performance, and meanwhile, the energy consumption is reduced.

Owner:NANTONG HUILI RUBBER

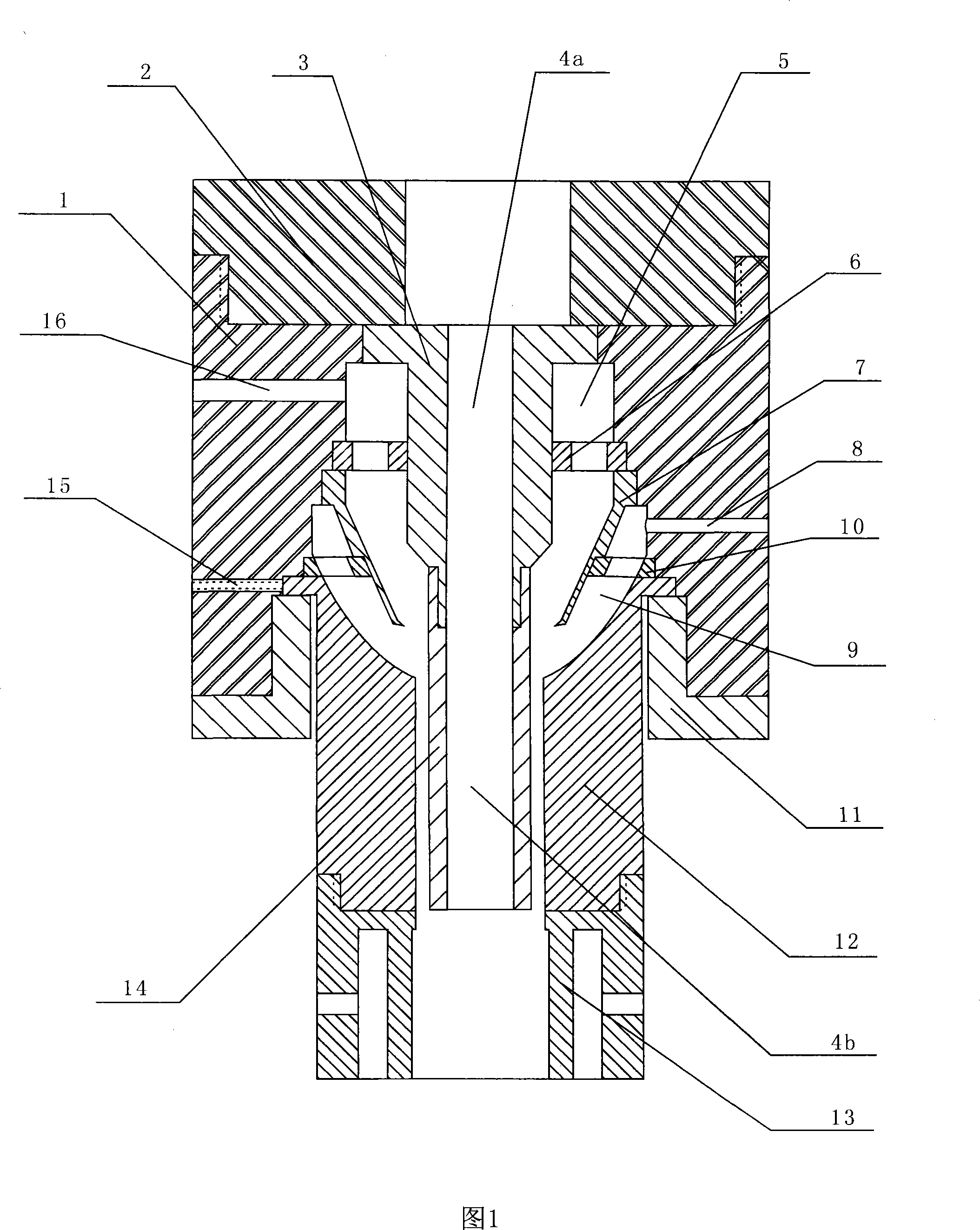

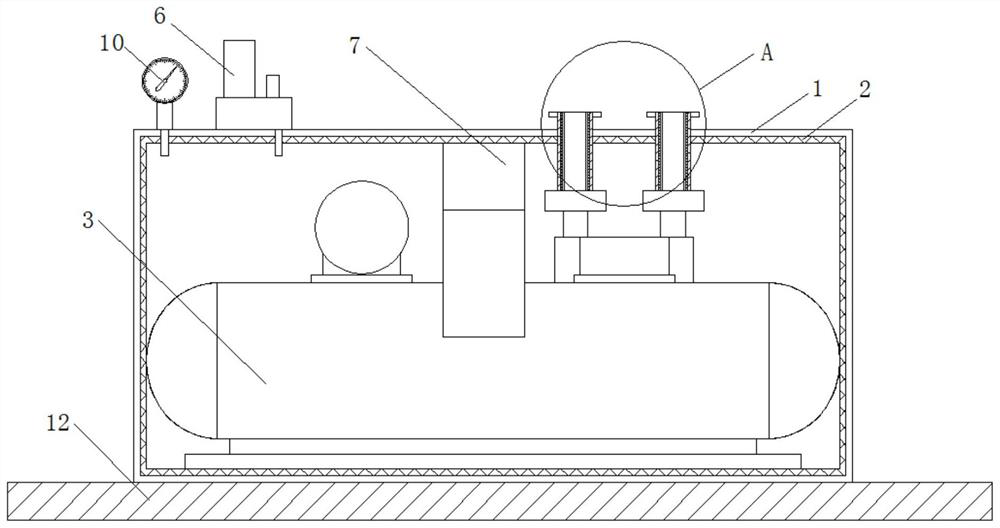

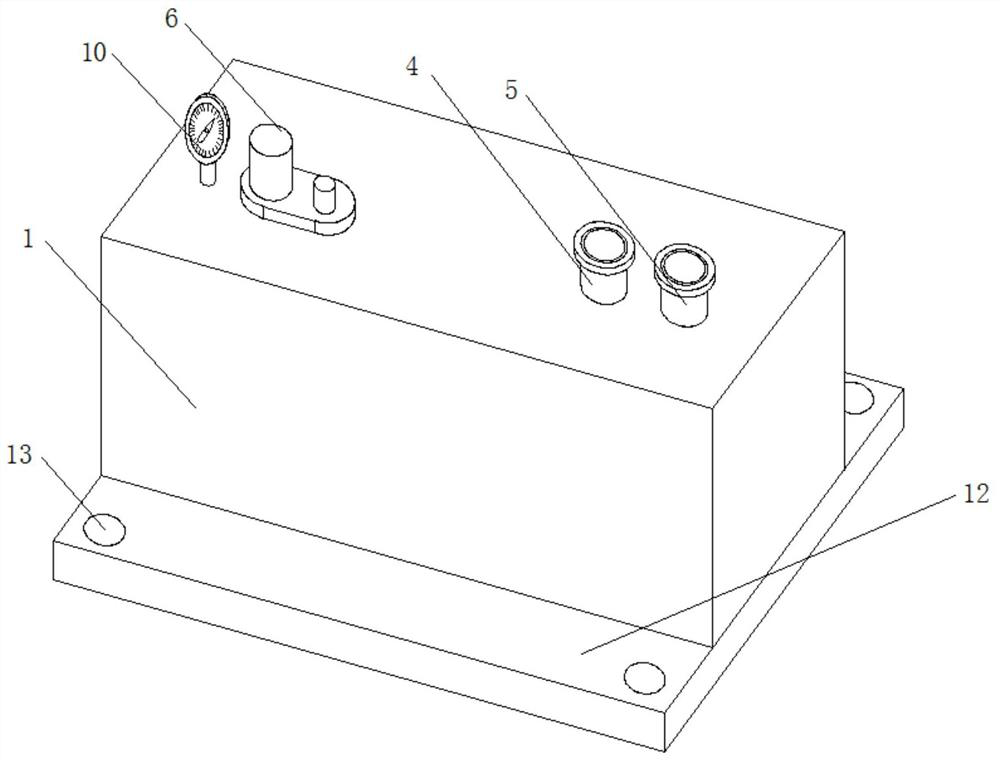

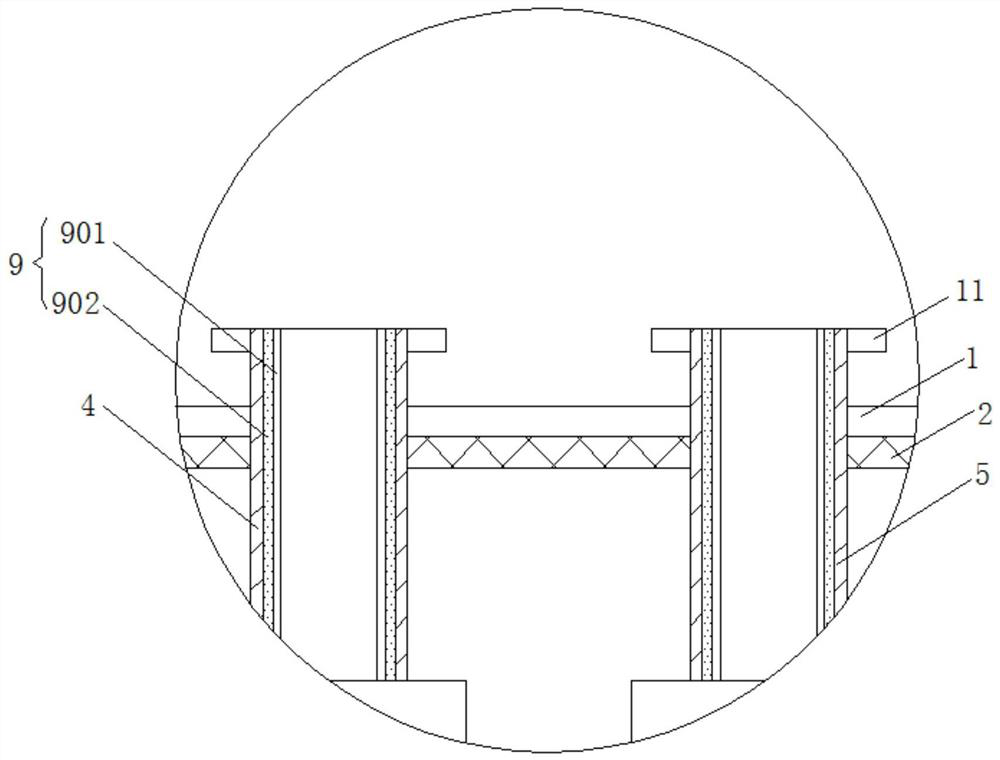

Noise reduction type gas compressor

InactiveCN112502940AReduce vibrationSmooth vibrationPositive displacement pump componentsPositive-displacement liquid enginesNoise generationGas compressor

The invention discloses a noise reduction type gas compressor, and belongs to the technical field of air compressors. The noise reduction type gas compressor comprises a sealing box, a noise reductioncomponent is fixedly connected to the inner wall of the sealing box, an air compressor body is fixedly installed at the bottom of the inner side of the sealing box, the air inlet end of the air compressor body is fixedly connected with an air inlet pipe communicating with the air compressor body, and the air outlet end of the air compressor body is fixedly connected with an exhaust pipe communicating with the air compressor body. According to the noise reduction type gas compressor, air on the outer side of the air compressor body is pumped away through a vacuum pump, transmission of noise ofthe air compressor body can be well weakened, meanwhile, a first reflecting layer, a second reflecting layer, a vacuum glass layer and the like can reflect and weaken noise, a damping layer can alsoreduce noise generated by the air inlet pipe and the exhaust pipe, a pressing block and an elastic pad can stabilize the air compressor body, the noise generation capacity of the air compressor body can be weakened, finally the influence of noise generated by a machine on the outside can be weakened, and harm to people is weakened.

Owner:BENGBU AUTO COMPRESSOR

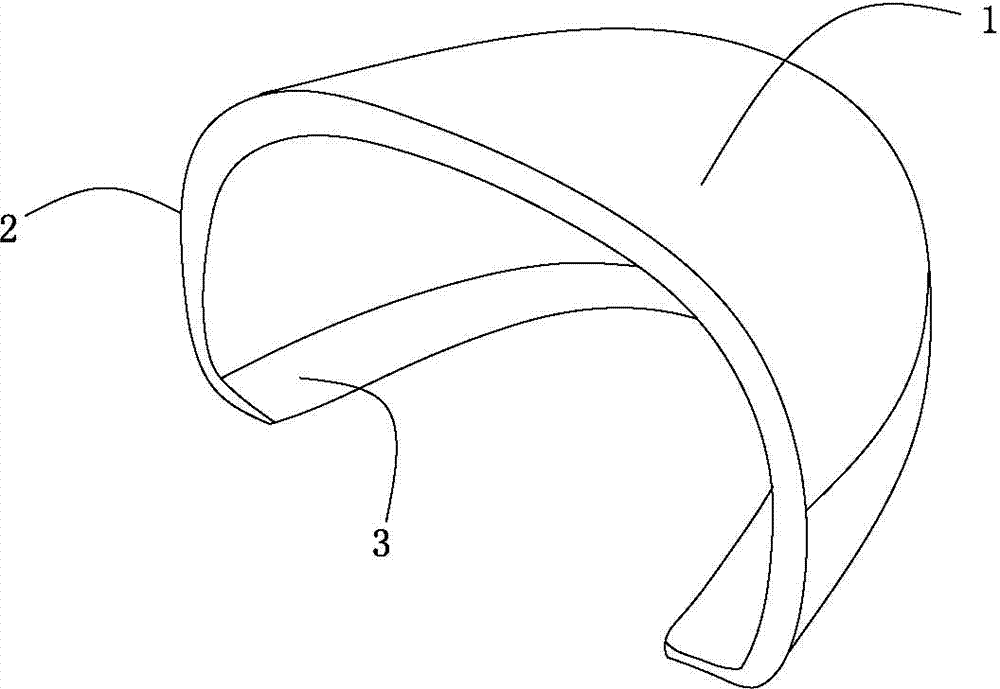

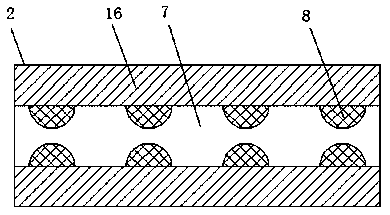

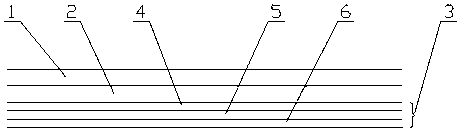

Composite film with high impact resistance

InactiveCN109435393AWith cold resistanceImprove bonding fastnessFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention discloses a composite film with high impact resistance. The composite film is characterized by being a three-layer structure, namely a printing layer (1), a binding agent layer (2) and aPE (polyethylene) layer (3) which are sequentially arranged from top to bottom, wherein the printing layer (1) is a casting nylon layer; the binding agent layer (2) is a double-component polyurethanebinding agent layer; the PE layer (3) is also of a three-layer structure, namely a first composite PE layer (4), a second composite PE layer (5) and a third composite PE layer (6) which are sequentially arranged from top to bottom; the first composite PE layer (4) consists of LLDPE (linear low density polyethylene) and an elastomer, and the elastomer accounts for 10% or more of the total mass ofthe first composite PE layer (4); the second composite PE layer (5) consists of LLDPE and LDPE (low density polyethylene) of equal mass; and the third composite PE layer (6) consists of MLLDPE (metallocene-based linear low density polyethylene)and LDPE of the equal mass.

Owner:DALIAN DAFU PLASTIC COLOR PRINTING

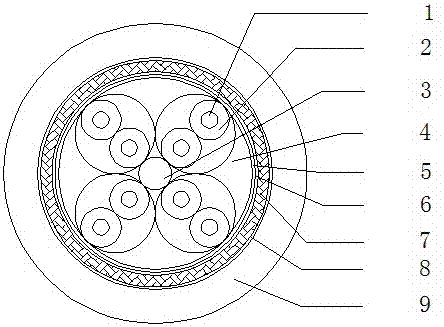

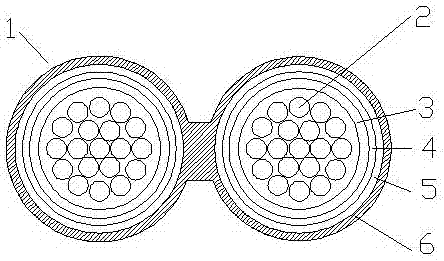

A watertight digital communication network cable for ships and a preparation method thereof

InactiveCN107039111ASealedWith high frequency transmission performanceQuad constructionsSubmarine cablesUltrasound attenuationElectrical conductor

The invention provides a watertight digital communication network cable for ships and a preparation method thereof. The watertight digital communication network cable comprises four pairs of network cable cores, a filling core, a sealing layer, a shielding layer, an A wrapping layer, a braided layer, a B wrapping layer and a sheath layer. Each pair of network cable cores comprise two conductors. Each conductor is externally provided with an insulation layer; the four pairs of network cable cores are externally wrapped by the shielding layer; the shielding layer is externally wrapped by the A wrapping layer; the A wrapping layer is externally wrapped by the braided layer; the braided layer is externally wrapped by the B wrapping layer; and the B wrapping layer is externally wrapped by the sheath layer. The advantages are that 1) the watertight digital communication network cable can prevent water from leaking from the internal portion of the cable structure into other cabins or into instrument equipment; 2) the watertight digital communication network cable has the advantages of flexibility, ageing resistance, ozone resistance, oil resistance, flame retardance, cold resistance, water absorption, longitudinal water seal, and can maintain excellent electrical and mechanical properties under hostile environment; and 3) the watertight digital communication network cable has the advantages of high impedance consistency, low attenuation and high near / far-end crosstalk disturbance guard degree.

Owner:NANJING QUANXIN CABLE TECH

Polyvinyl acetate adhesive

InactiveCN103555234AWater resistantHeat resistantNon-macromolecular adhesive additivesGraft polymer adhesivesAdhesivePhthalate

The invention relates to the field of adhesives, and particularly relates to a polyvinyl acetate adhesive which is characterized by comprising the following components in parts by weight: 100 parts of water, 6-8 parts of polyvinyl alcohol, 40 parts of vinyl acetate, 0.5-0.8 part of propyl alcohol, 1 part of copolymerization catalyst, 4-6 parts of hydrogen peroxide diisopropylbenzene, 1-2 parts of diisooctyl phthalate and 2-3 parts of anti-aging agent. Compared with the prior art, the polyvinyl acetate adhesive provided by the invention has the advantages of good water resistance, heat resistance, cold resistance and initial adhesion, high bonding strength and the like, and can be used as high-quality white latex to replace common white latex.

Owner:林贤文

Environment-friendly DC 1500V mouse-proof and anti-termite cable used for photovoltaic power generation system

InactiveCN107221381AMeet needsHigh mechanical strengthPlastic/resin/waxes insulatorsInsulated cablesCopper conductorPolyolefin

The invention discloses an environment-friendly DC 1500V mouse-proof and anti-termite cable used for a photovoltaic power generation system. The cable comprises a cable body which comprises two cable units. The two cable units are symmetrically arranged. Each cable unit comprises copper conductor wire cores, an irradiation crosslinked flame-retardant polyolefin insulating layer, a flame-retardant tape layer, an oxygen insulation layer and an irradiation crosslinked flame-retardant polyolefin external sheath which are arranged from inside to outside in turn. The two cable units are connected into an integrated structure through the irradiation crosslinked mouse-proof and anti-termite flame-retardant polyolefin external sheath. The material structure of the high-temperature-resistant 150 DEG C irradiation crosslinked flame-retardant polyolefin insulating layer and the high-temperature-resistant 150 DEG C irradiation crosslinked mouse-proof and anti-termite flame-retardant polyolefin external sheath is adopted so that the cable has the cold-resistant, heat-resistant, ultraviolet-resistant, ozone-resistant and mouse-proof and anti-termite characteristics and has high mechanical strength and acid and alkali resistance, moisture and heat resistance and halogen-free, low-smoke and flame-retardant performance and thus the demands of the market and the customers can be fully met.

Owner:ANHUI HUATONG CABLE GRP

Crossbreeding culturing method of Jinhua pigs containing wild boar blood lineage

InactiveCN108271738ABright red muscle colorStrong waterFood processingClimate change adaptationFeral pigJinhua pig

The invention discloses a crossbreeding culturing method of Jinhua pigs containing wild boar blood lineage. By crossbreeding Southern and Northern wild boars and sows, an F1-generation core herd is obtained, the high-quality F1-generation core herd is crossbred with boars and sows of Taihu black pigs to obtain an F2-generation core herd, the high-quality F2-generation core herd is crossbred with boars and sows of Huainan black pigs to obtain an F3-generation core herd, and the high-quality F3-generation core herd is crossbred with boars and sows of the Jinhua pigs to obtain F4-generation Jinhua pigs containing the wild boar blood lineage. The Jinhua pigs containing the wild boar blood lineage cultured according to the crossbreeding and culturing method contain the blood lineage of Southernwild boars, Northern wild boars, Taihu black pigs and Huainan black pigs simultaneously, so that according to the improved variety, the body form becomes large, the growth and development speed becomes high, the variety is resistant to cold, heat and diseases, the Jinhua pigs are fond of eating green feed, and the pork quality and the color characteristic of the Jinhua pigs are kept.

Owner:浙江甘源泓农业科技有限公司

Cuttage breeding method for improving cold resistance of pitaya

PendingCN113994820APlay a protective effectImprove survival ratePlant growth regulatorsCalcareous fertilisersNutrient solutionCold resistance

The invention discloses a cuttage breeding method for improving cold resistance of pitaya, which comprises the following steps: S1, selecting robust branches, cutting off the branches, and carrying out cuttage to obtain pitaya rooting seedlings; s2, transplanting the pitaya rooted seedlings into a plastic greenhouse, immediately irrigating the pitaya rooted seedlings with root fixing water, and spraying a nutrient solution after 2-5 days; s3, controlling the temperature in the greenhouse to be 5-9 DEG C, and spraying a nutrient solution; after the seedlings are cultured for 3-4 months, removing dead seedlings, adjusting the temperature to be-5 DEG C to 5 DEG C, and spraying a nutrient solution; continuously culturing for 3-4 months, and removing dead nursery stocks at the same time; s4, transplanting the seedlings subjected to low-temperature treatment into a natural environment for continuous growth, harvesting after seeds are mature, continuously sowing the cold-resistant pitaya, selfing the cold-resistant pitaya, and selecting branches or seeds with excellent and stable characters from offspring of the cold-resistant pitaya to cultivate the cold-resistant pitaya. The problem of poor cold resistance of pitaya can be solved, and the low-temperature treatment survival rate and yield of pitaya are improved.

Owner:广西海泉农业有限公司

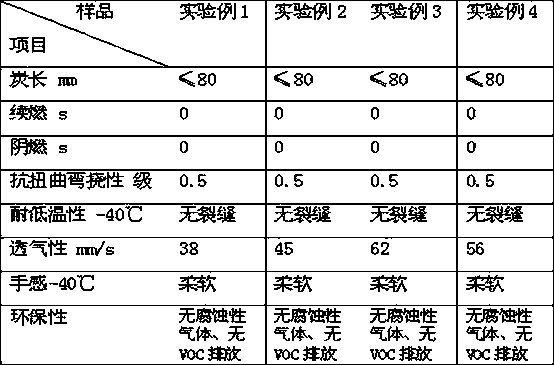

Cold-resistant, twist-resistant, flame-retardant foam coating glue for textiles and its treatment method

The invention provides a cold-resistant anti-twisting anti-bending flame-retardant foamed coating adhesive for a textile and a treating method. The cold-resistant anti-twisting anti-bending flame-retardant foamed coating adhesive is prepared by uniformly mixing, by weight, 80 to 100 of a flexible and elastic foamed coating adhesive, 2 to 4 of an enclosed type isocyanate cross-linking agent and 1 to 3 of a high-permeability softening agent under stirring, then adding 20 to 25 of crystal II type ammonium polyphosphate, 10 to 15 of expandable graphite and 4 to 6 of micro polytetrafluoroethylene powder, and adequately introducing air until a foaming state is reached so as to allow the size of the obtained mixture to increase by 1 to 3 times so as to obtain the coating adhesive. A fabric is subjected to calendering pretreatment and then coated with the prepared coating adhesive. The coating adhesive is simple and convenient to produce, effectively overcomes the problem of hygroscopicity of ammonium polyphosphate and the problem of meltability of a flame-retardant textile, and has good flame retardation, cold resistance, twisting resistance, bending resistance and air permeability; and the treated fabric has good elasticity and is comfortable to wear.

Owner:DANDONG UNIK TEXTILE

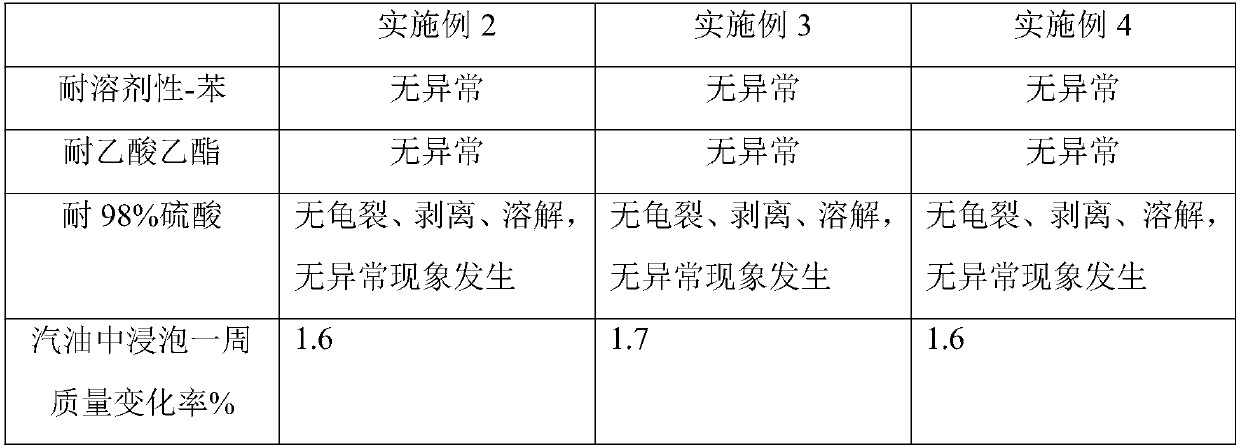

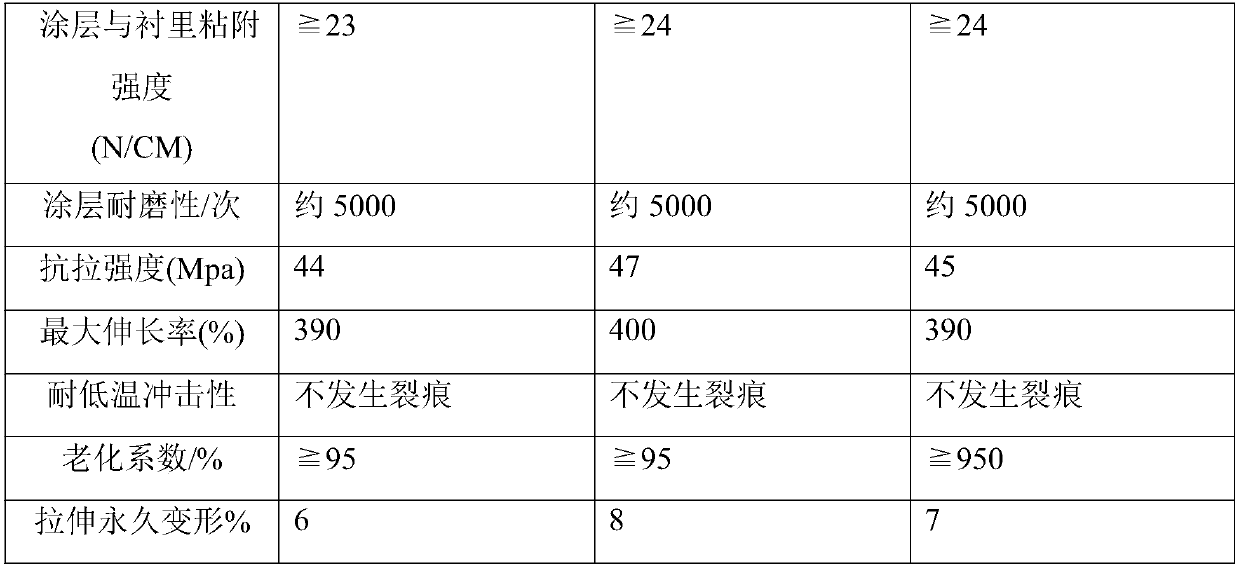

Method for processing faux suede membrana dermalis coating

ActiveCN103657981BHigh strengthHigh elongation at breakPretreated surfacesPolyurea/polyurethane coatingsAdhesiveCross linker

The invention discloses a method for processing a faux suede membrana dermalis coating. The method comprises the following steps: (1) bottom layer rubber coating preparation, namely, evenly stirring 100 parts of polyurethane resin, 0.5-1 part of polyurethane thickening agent, 0.5-2 parts of melamine cross-linking agents, 4-10 parts of foam stabilizers and 1-3 parts of foaming agents and increasing the foaming size to 1-3 times, (2) facial layer rubber coating preparation, namely, evenly stirring 100 parts of coldness-resistant lightless coating adhesive, 5-10 parts of amidogen modified polysiloxane, 0.5-2 parts of cross-linking agents and color paste, (3) adopting a dry method to coat directly, increasing the dry weight of the bottom layer rubber coating by 5-8g / m2, using a planishing mill for calendaring, and increasing the dry weight of the facial layer rubber coating by 7-10g / m2. The method is simple in technology and feasible, improves the distortion and bending resistance, elasticity and softness of fabric, improves dry-wet friction firmness, wear-resisting performance and coldness resistance of the fabric, and does not influence in index of the fabric.

Owner:DANDONG UNIK TEXTILE

A kind of regenerated rubber and the tire made of the rubber

The invention provides reclaimed rubber and a tire made thereof. The reclaimed rubber comprises the following materials: waste tire rubber powder, glass fibers, nylon fibers, acrylic polyurethane, polyamide, styrenated phenol, 3-diphenylguanidine, polystyrene resin, an epoxy resin composition, abietic acid, rosin anhydride, carbon black, aromatic disulfide and zinc salt. The tire made of the reclaimed rubber comprises a tire body; the tire body comprises two tire side surfaces and a tire peripheral surface positioned between the two tire side surfaces; air guide blocks are distributed on at least one tire side surface, and an air guide groove is formed between the two adjacent air guide blocks; multi-ring brake pattern blocks are arranged on the tire peripheral surface and are symmetrically arranged about a center line of the tire peripheral surface, a flow guide groove is formed between the two adjacent brake pattern blocks on the same ring, and the air guide groove is connected with the flow guide groove. The reclaimed rubber provided by the invention is high in mechanical strength, strong in elasticity, aging-resistant, cold-resistant, high temperature-resistant and strong in braking performance and driving performance, and meanwhile, the energy consumption is reduced.

Owner:NANTONG HUILI RUBBER

A sweet orange cold resistance gene cslac18 and its application

ActiveCN111961680BPossesses the function of positively regulating cold resistanceWith cold resistanceOxidoreductasesFermentationBiotechnologyNicotiana tabacum

The present invention proposes a cold resistance functional gene CsLac18 isolated and cloned from sweet orange, its nucleotide sequence is shown in SEQ ID NO.1, and its corresponding amino acid sequence is shown in SEQ ID NO.2. The gene CsLac18 of the present invention was introduced into tobacco and Citrus aurantii for functional verification, and it was found that the obtained transgene overexpression plants had significantly improved cold resistance, while the transgene silent expression plants had significantly reduced cold resistance. The invention provides important gene resources for plant cold-resistant genetic engineering and can improve the cold-resistant performance of plants.

Owner:YANGZHOU UNIV

Foaming process of water-borne polyurethane foam for finished automobile

The invention aims to provide a foaming process of water-borne polyurethane foam for a finished automobile. The foaming process comprises steps as follows: (1) the water-borne polyurethane foam is prepared from components in parts as follows: 40-45 parts of water-borne polyether polyol, 40-45 parts of dichloro hydrogen acid ester, 8-10 parts of silicon whisker and 3-5 parts of glass fibers; (2) the components of the water-borne polyurethane foam in the step (1) are sufficiently mixed and uniformly stirred in parts and then subjected to extrusion palletization through an extruder; (3) an extruded material in the extrusion pelletizer is put in a prepared foaming mold for foaming, and the foamed sponge foam is cured after being placed at the set distance. The foam has the effects of sound insulation, heat insulation, shock resistance, electric insulation, heat resistance, cold resistance and the like, has good moisture absorption performance, can keep inside environment of the automobiledry and has high waterproof and adhesion properties.

Owner:ANHUI ZHICHENG ELECTROMECHANICAL SPARE PARTS

Heat insulation and preservation glass

InactiveCN106084933AImprove heat insulationImprove insulation effectAnti-corrosive paintsElectrically-conductive paintsThermal insulationPhenyl Ethers

The invention discloses heat insulation and preservation glass. The heat insulation and preservation glass is prepared from, by weight, 4-5 parts of calcium hexaluminate, 2-4 parts of nano cerium oxide, 5-8 parts of nanometer titania, 0.5-1.5 parts of palladium nitrate, 60-80 parts of silicon dioxide, 3-6 parts of sodium hydrogen phosphate, 4-6 parts of sodium pyrophosphate, 2-15 parts of boric oxide, 4-6 parts of sodium oxalate, 10-25 parts of aluminum oxide, 5-10 parts of poly-amino resin, 1-2 parts of disulfoxide alkylene diol phenyl ether, 2-2.5 parts of dodecyl aminopropionic acid, 1-1.5 parts of methyl methacrylate, 1-1.5 parts of modified polysiloxane, 1-1.5 parts of zinc oxide, 1-1.5 parts of allyl heptanoate and 1-1.5 parts of methyl methyacrlate. The glass has the advantages of insulating heat, preserving heat and resisting cold, explosions, corrosion, bacteria and static.

Owner:安徽有通玻璃有限公司

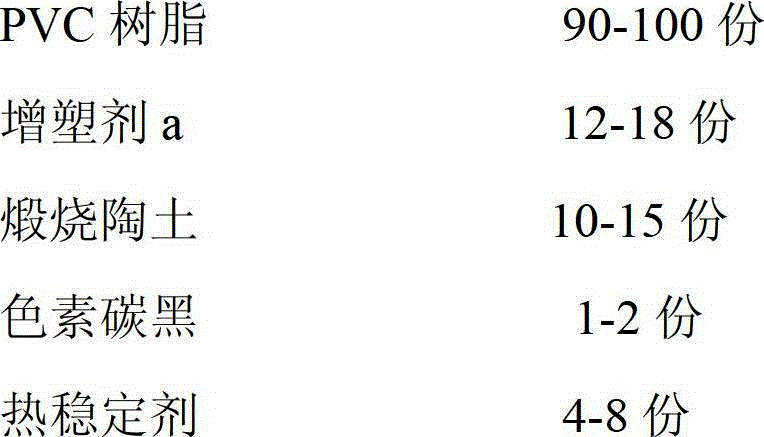

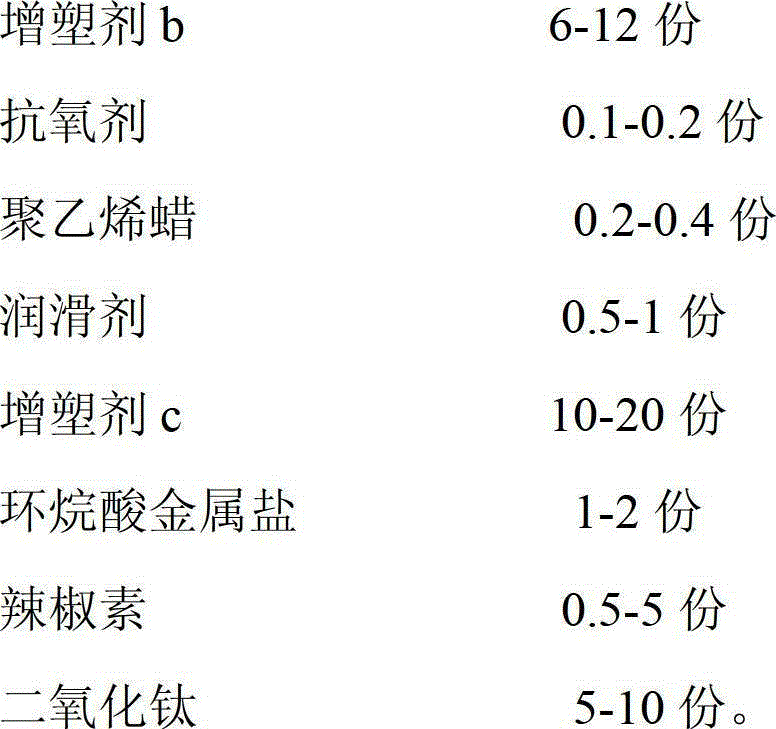

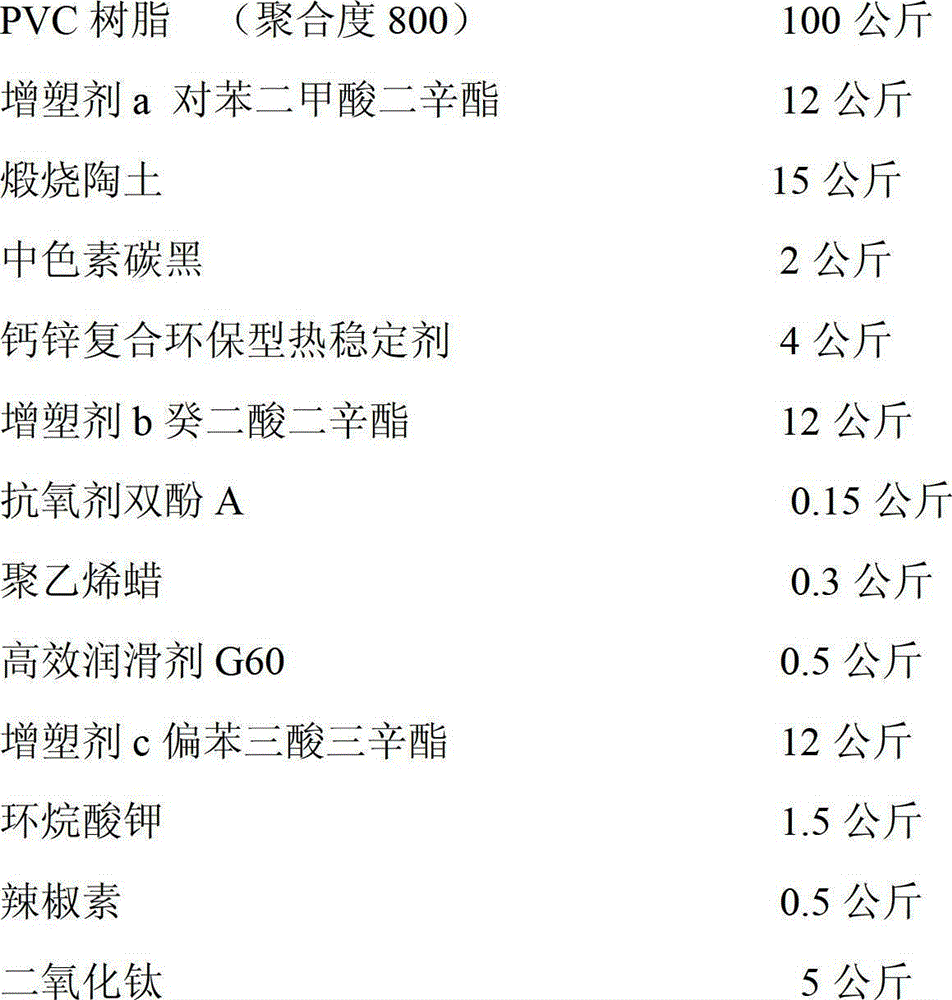

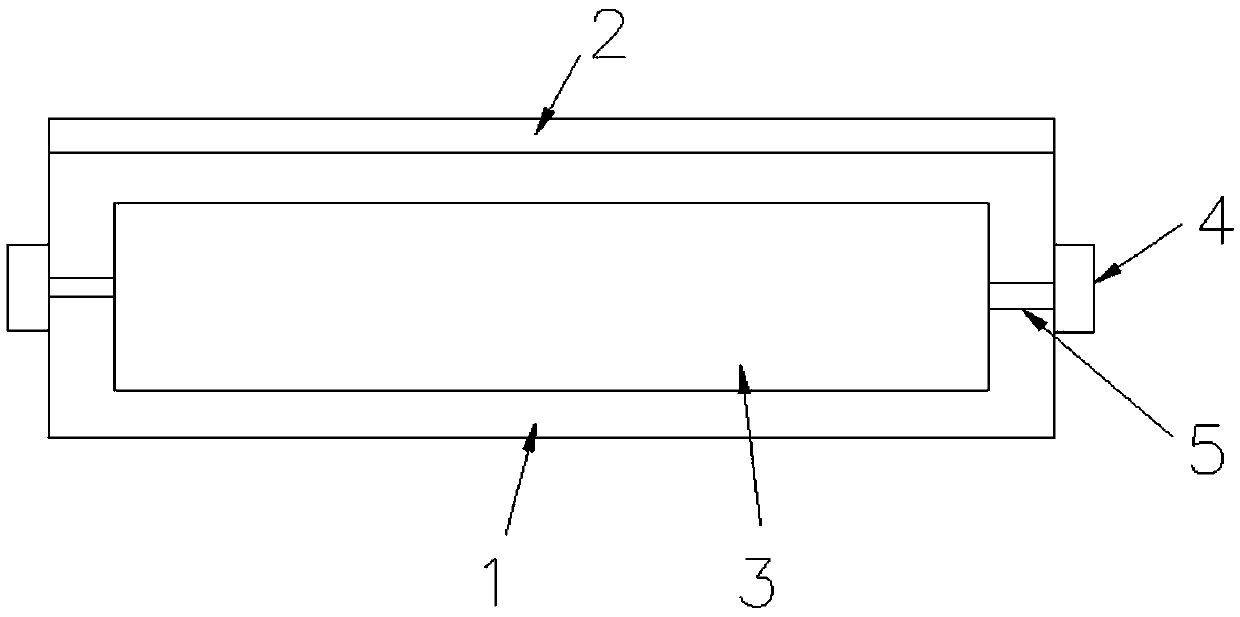

Cold-resistant insulating grade PVC sheath material for extra-high voltage cables and its preparation

ActiveCN103788529BImprove electrical performanceEasy to processPlastic/resin/waxes insulatorsInsulated cablesWaxMaterials preparation

The invention discloses a cold-resistant insulating level PVC (polyvinyl chloride) sheath material for an extra-high-tension cable and preparation thereof. The raw material of the cold-resistant insulating level PVC sheath material for an extra-high-tension cable comprises the following components in parts by weight: 90-100 parts of PVC resin, 12-18 parts of plasticizer a, 10-15 parts of calcined argil, 1-2 parts of color black, 4-8 parts of heat stabilizer, 6-12 parts of plasticizer b, 0.1-0.2 part of antioxidant, 0.2-0.4 part of polyethylene wax, 0.5-1 part of lubricant, 10-20 parts of plasticizer c, 1-2 parts of metal naphthenate, 0.5-5 parts of capsaicine and 5-10 parts of titanium dioxide. The cold-resistant insulating level PVC sheath material for an extra-high-tension cable, disclosed by the invention, can be widely applied to the cold-resistant level and rat-proof and termite-proof outer sheath for an extra-high-tension cable.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

Graphene solar cell and preparation method thereof

InactiveCN107731944AIncrease profitWith insulationPhotovoltaic energy generationSemiconductor devicesGlass coverSolar cell

The invention discloses a graphene solar cell and a preparation method thereof. The graphene solar cell comprises a transparent glass outer shell, wherein a glass cover plate is arranged at the top ofthe transparent glass outer shell, a graphene power generation material is placed in an inner cavity of the transparent glass outer shell, electrode plates are respectively arranged at two sides of the transparent glass outer shell, and inner sides of the electrode plates are connected with the graphene power generation material via leads. The graphene solar cell is simple in structural principleand is convenient to fabricate, and the solar utilization ratio can be effectively improved; and moreover, the employed transparent glass outer shell has the advantages of heat preservation, cold resistance, explosion prevention and corrosion resistance, and the service lifetime of the solar cell is prolonged.

Owner:BEIJING JUNXIU CONSULTATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com