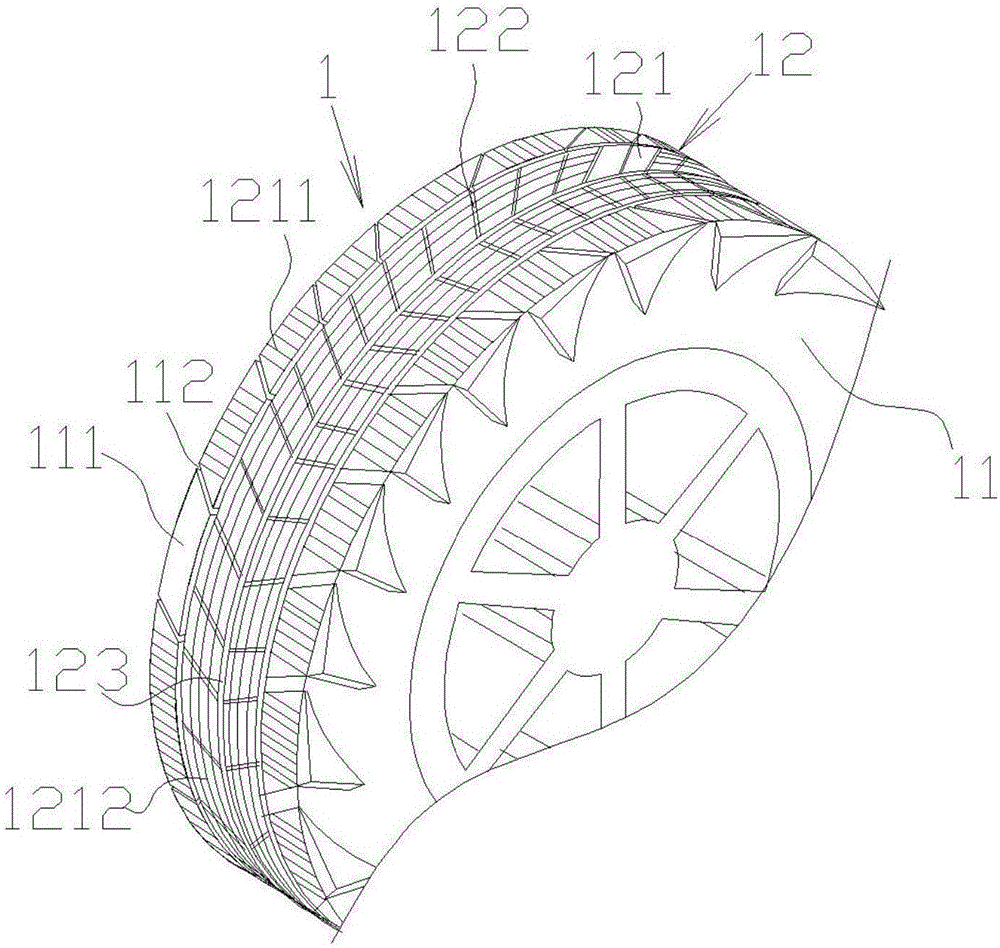

Reclaimed rubber and tire made thereof

A technology for reclaimed rubber and tires, applied in the field of rubber, can solve the problems of elasticity, low aging resistance and cold resistance, low strength, etc., and achieve the effects of good processing performance, high tensile strength and strong elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

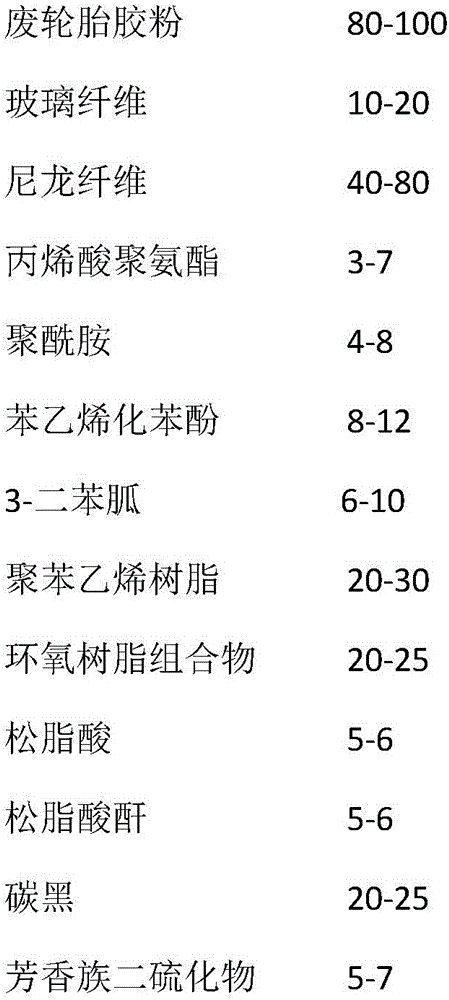

[0027] A regenerated rubber disclosed in the present invention comprises the following materials in parts by weight: 80 parts of waste tire rubber powder, 10 parts of glass fiber, 40 parts of nylon fiber, 3 parts of acrylic polyurethane, 4 parts of polyamide, 8 parts of styrenated phenol, 6 parts of 3-diphenylguanidine, 20 parts of polystyrene resin, 20 parts of epoxy resin composition, 5 parts of rosinic acid, 5 parts of rosinic anhydride, 20 parts of carbon black, 5 parts of aromatic disulfide, 5 parts of zinc salt .

[0028] Preferably, the epoxy resin composition comprises the following materials in weight percentage: epoxy resin 60%, pyrogallol-divinylbenzene polycondensation resin: 20%, silicon dioxide 6%, diphenylmethane diisocyanate 14% .

[0029] The preparation method of the above-mentioned epoxy resin composition is: take the above-mentioned epoxy resin and heat it to 50°C in a vacuum reactor, stir at a stirring speed of 200r / min, and add silicon dioxide at a speed...

Embodiment 2

[0033] A regenerated rubber disclosed by the present invention comprises the following materials in parts by weight: 100 parts of waste tire rubber powder, 20 parts of glass fiber, 80 parts of nylon fiber, 7 parts of acrylic polyurethane, 8 parts of polyamide, 12 parts of styrenated phenol, 10 parts of 3-diphenylguanidine, 30 parts of polystyrene resin, 25 parts of epoxy resin composition, 6 parts of rosinic acid, 6 parts of rosin anhydride, 25 parts of carbon black, 7 parts of aromatic disulfide, 8 parts of zinc salt share.

[0034] Preferably, the epoxy resin composition comprises the following materials in weight percentage: epoxy resin 10%, pyrogallol-divinylbenzene polycondensation resin: 60%, silicon dioxide 5%, diphenylmethane diisocyanate 25% . Preferably, the aromatic disulfide is a mixture of zinc pentachlorothiophene and thionaphthol, and more preferably, the mass ratio of zinc pentachlorothiophene and thionaphthol is 6:4.

[0035]The preparation method of the abo...

Embodiment 3

[0038] A regenerated rubber disclosed by the present invention comprises the following materials in parts by weight: 90 parts of waste tire rubber powder, 15 parts of glass fiber, 60 parts of nylon fiber, 5 parts of acrylic polyurethane, 6 parts of polyamide, 10 parts of styrenated phenol, 8 parts of 3-diphenylguanidine, 25 parts of polystyrene resin, 22 parts of epoxy resin composition, 5 parts of rosinic acid, 5 parts of rosin anhydride, 22 parts of carbon black, 6 parts of aromatic disulfide, 7 parts of zinc salt share.

[0039] Preferably, the epoxy resin composition includes the following materials in weight percentage: 30% epoxy resin, pyrogallol-divinylbenzene polycondensation resin: 40%, silicon dioxide 10%, diphenylmethane diisocyanate 20% .

[0040] The preparation method of the above-mentioned epoxy resin composition is: take the above-mentioned epoxy resin and heat it to 70°C in a vacuum reactor, stir at a stirring speed of 300r / min, and add silicon dioxide at a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com