Halogen-free flame-retardant silicone rubber wire and cable material and preparation method thereof

A wire and cable and silicone rubber technology, which is applied in the field of halogen-free flame retardant silicone rubber wire and cable materials and its preparation, can solve the problem of poor compatibility between aluminum hydroxide and silicone rubber, unsatisfactory effect of silicone rubber wrapping, and flame retardant. Unsatisfactory effect and other problems, to achieve the effect of outstanding anti-aging performance, soft structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

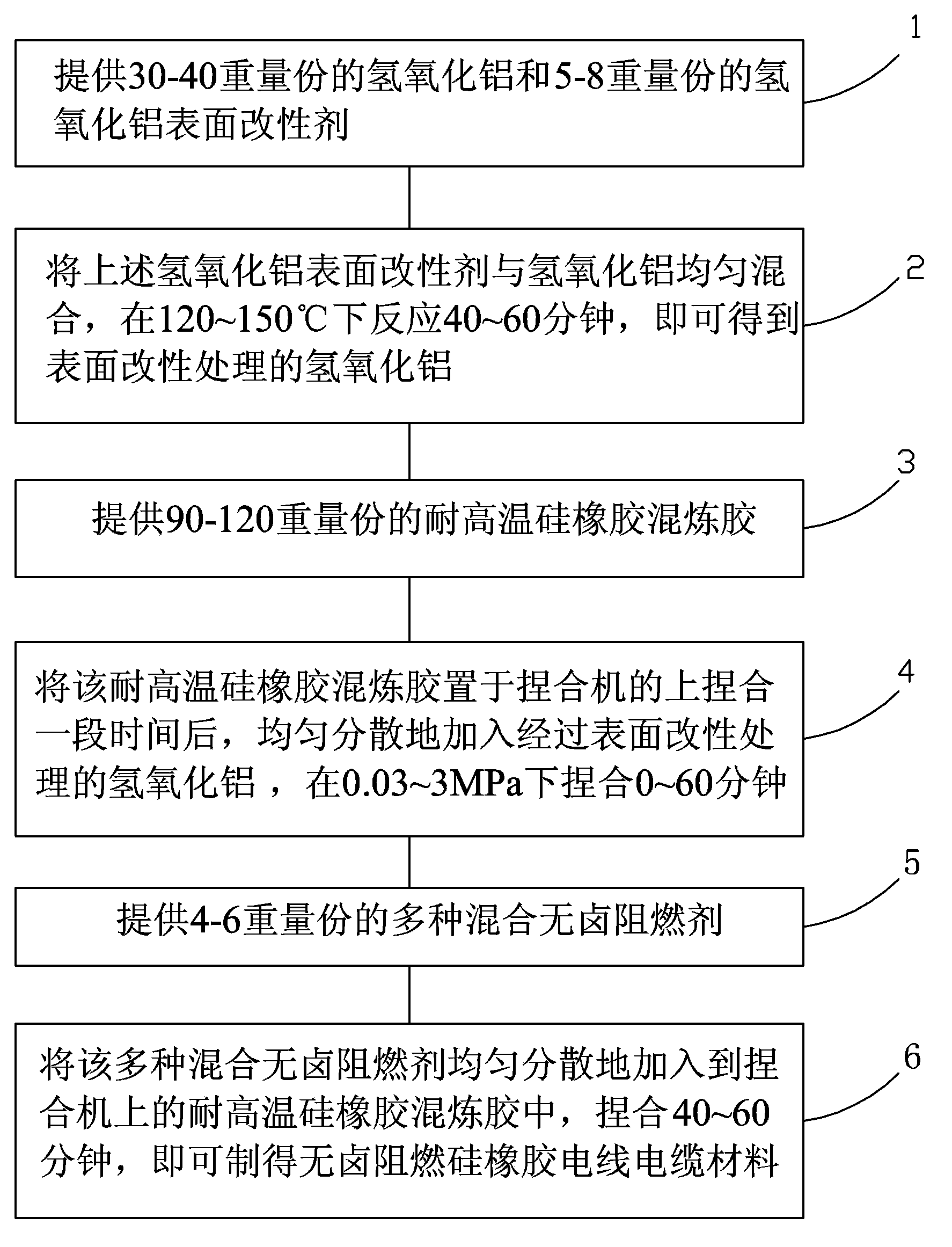

[0030] The preparation method of the halogen-free flame-retardant silicone rubber wire and cable material of the present invention comprises the following steps:

[0031] Step 1, providing 30-40 parts by weight of aluminum hydroxide and 5-8 parts by weight of aluminum hydroxide surface modifier;

[0032] Step 2, uniformly mixing the above-mentioned aluminum hydroxide surface modifier with aluminum hydroxide, and reacting at 120-150°C for 40-60 minutes to obtain surface-modified aluminum hydroxide;

[0033] The aluminum hydroxide surface modifying agent is hexamethyldisilazane, and the aluminum hydroxide is modified through the surface treatment of hexamethyldisilazane to reduce its surface energy, thereby reducing the polarity of aluminum hydroxide, making It has better compatibility with high temperature resistant silicone rubber compound;

[0034] Step 3, providing 90-120 parts by weight of high temperature resistant silicone rubber compound;

[0035] The high-temperature-...

Embodiment 1

[0043] Provide 35 parts by weight of aluminum hydroxide and 6 parts by weight of hexamethyldisilazane, mix them uniformly, and react at 120-150°C for 40-60 minutes to obtain surface-modified aluminum hydroxide; Put 100 parts by weight of high-temperature-resistant silicone rubber compound on the kneader and knead for a period of time, then add surface-modified aluminum hydroxide evenly and dispersedly, and knead for 0-60 minutes at 2-3 MPa; A variety of mixed halogen-free flame retardants in parts by weight are uniformly and dispersedly added to the high-temperature-resistant silicone rubber compound on the kneader, and kneaded for 40 to 60 minutes to obtain a halogen-free flame-retardant silicone rubber wire and cable material.

[0044] In summary, the halogen-free flame-retardant silicone rubber wire and cable material of the present invention can achieve excellent flame-retardant effect, and has excellent insulation, mechanical properties, aging resistance and environmental ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com