Cold-resistant insulating grade PVC sheath material for extra-high voltage cables and its preparation

A cold-resistant insulation and ultra-high voltage technology, applied in the direction of insulated conductors, insulated cables, organic insulators, etc., can solve the problems of non-rat proof, termite proof, low volume resistance, etc., and achieve excellent processing performance and excellent electrical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

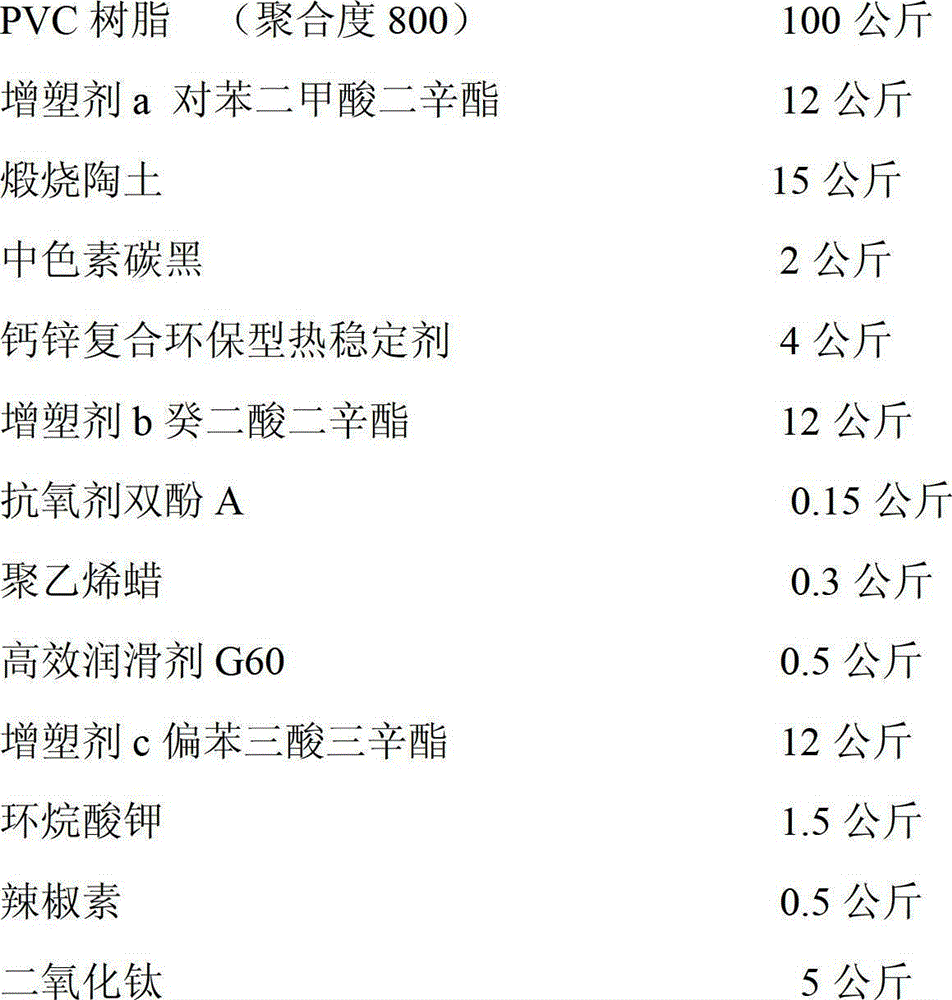

[0023] 1. Experimental materials

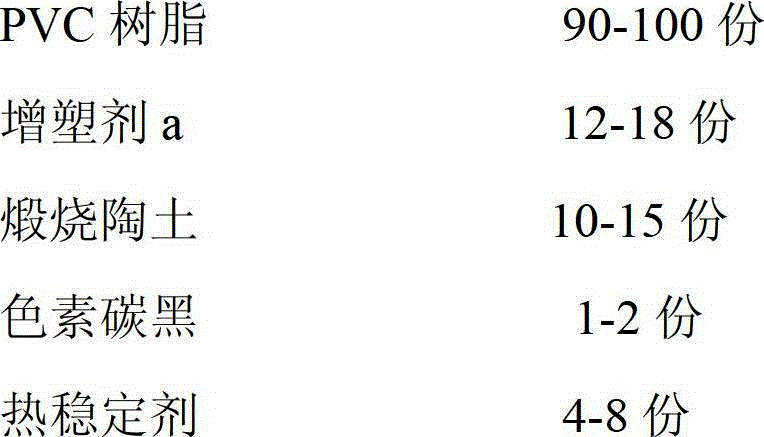

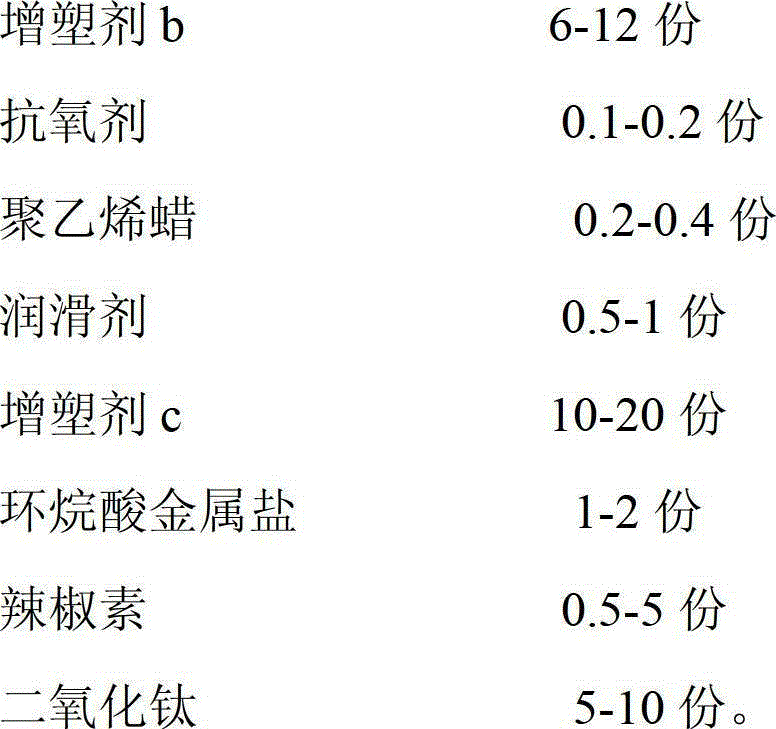

[0024]

[0025] 2. Preparation method:

[0026] a, 100 kilograms of ground slurry material and PVC resin, 15 kilograms of calcined pottery clay, 2 kilograms of medium pigment carbon black, 12 kilograms of plasticizer a dioctyl terephthalate, 4 kilograms of compound environment-friendly heat stabilizers, Plasticizer b dioctyl sebacate 12 kg, polyethylene wax 0.3 kg, high-efficiency lubricant G600.5 kg, plasticizer c trioctyl trimellitate 12 kg, antioxidant bisphenol A 0.15 kg , 1.5 kilograms of potassium naphthenate, 0.5 kilograms of capsaicin, and 5 kilograms of titanium dioxide are placed in a high-speed kneader and heated for high-speed stirring. The temperature of the high-speed kneader is controlled at 100-120 ° C, and the kneading time is 5-10 minutes;

[0027] b. The uniformly stirred raw materials are directly fed into the twin-screw feeder for extrusion, and the heating temperature of each section of the twin-screw feeder is equal...

Embodiment 2

[0030] 1. Experimental materials

[0031]

[0032] 2. Preparation method

[0033] Using the raw materials of this example, the method for preparing the cold-resistant insulating grade PVC sheath material for extra-high voltage cables is the same as that in Example 1.

Embodiment 3

[0035] 1. Experimental materials

[0036]

[0037]

[0038] 2. Preparation method

[0039] Using the raw materials of this example, the method for preparing the cold-resistant insulating grade PVC sheath material for extra-high voltage cables is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com