Preparation method of ammonium dimolybdate

A technology of ammonium dimolybdate and ammonium tetramolybdate, which is applied in the fields of chemical instruments and methods, molybdenum compounds, inorganic chemistry, etc., and can solve problems such as mixing of impurities, shortage of water resources, difficulty in controlling the purity of ammonium dimolybdate products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a kind of preparation method of ammonium dimolybdate, comprises the following steps:

[0023] The molybdenum source and the ammonium source are subjected to a metathesis reaction to obtain ammonium dimolybdate;

[0024] The molybdenum source is ammonium tetramolybdate and / or molybdic acid;

[0025] The ammonium source is one or more of ammonia water, ammonium bicarbonate and ammonium carbonate.

[0026] In the invention, the molybdenum source and the ammonium source are subjected to metathesis reaction to obtain ammonium dimolybdate. In the present invention, the molybdenum source is ammonium tetramolybdate and / or molybdic acid; the ammonium source is one or more of ammonia water, ammonium bicarbonate and ammonium carbonate. The present invention does not have any special requirements on the source of the molybdenum source and the ammonium source, and the commercially available molybdenum source and ammonium source well known to those skilled in...

Embodiment 1

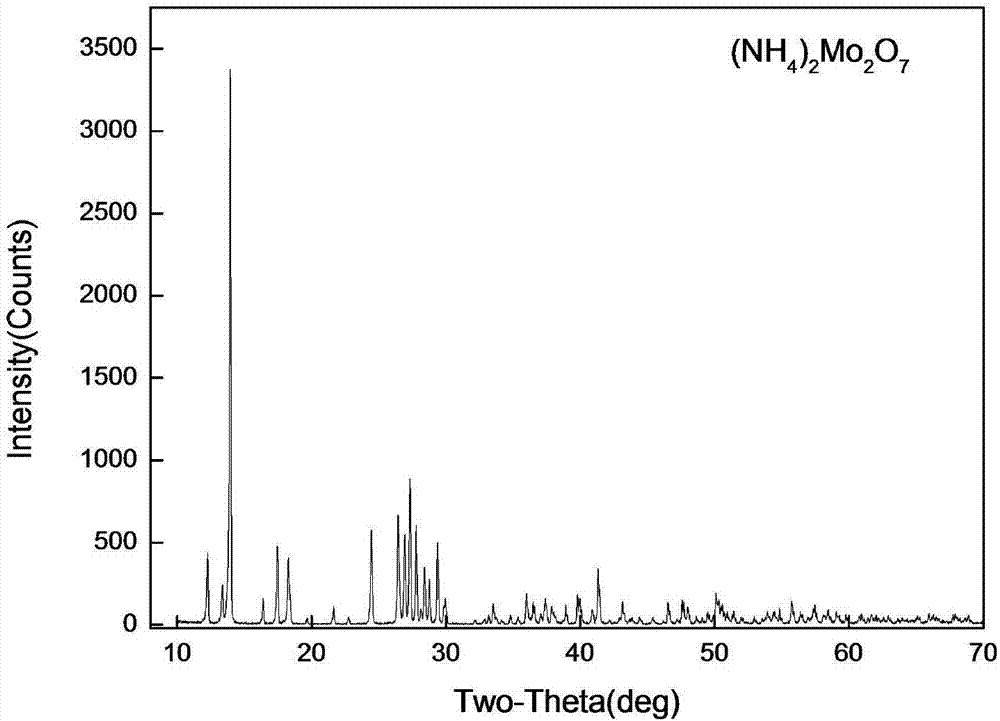

[0057] The mass ratio of ammonium tetramolybdate, ammonium bicarbonate and water is 15:3.9:0.25, mix evenly, the temperature is 80°C, the pressure is 0.13MPa, and the reaction time is 2h to obtain the ammonium dimolybdate product. The ammonium dimolybdate that the present embodiment obtains carries out X-ray detection, and its result is as follows figure 1 shown. The X-ray diffraction analysis results show that the product has a single phase, and the ammonium dimolybdate product has a purity >99%.

Embodiment 2

[0059] The mass ratio of ammonium tetramolybdate, ammonium bicarbonate and water is 15:4.2:0.5, mix uniformly, the temperature is 60°C, the pressure is 0.12MPa, and the reaction time is 2h, the product is obtained. The X-ray diffraction analysis results show that there is The phase is single, and the purity of the ammonium dimolybdate product is >99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com