PU polyether polyurethane

A polyether polyurethane and polyether technology, applied in the field of polyurethane materials, can solve the problems of difficulty in decomposition, rising prices of petrochemical products, and high stability of polyurethane, and achieve the effects of reducing tension, saving social resources and alleviating price increases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

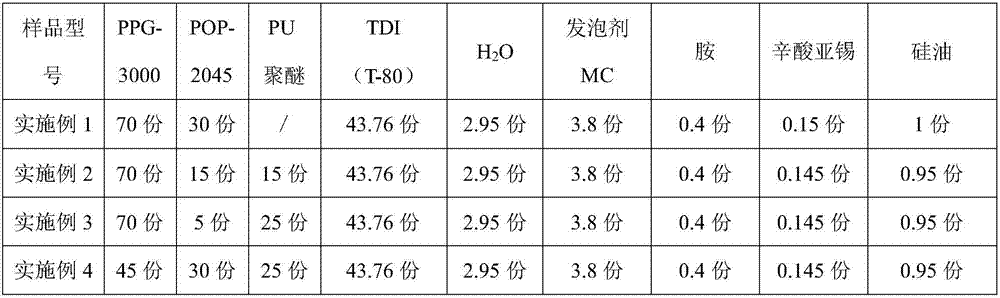

Method used

Image

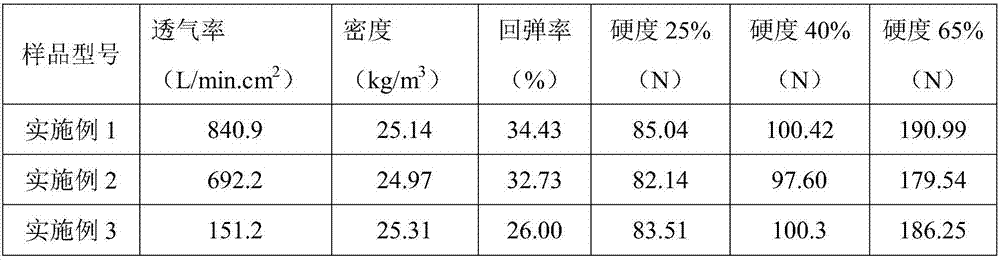

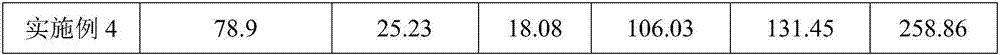

Examples

Embodiment 1

[0027] The emulsification time of Example 1 is about 14S, the reaction is moderate, a large amount of foaming and exhausting, and a slight drop.

Embodiment 2

[0028] The emulsification time of Example 2 is about 16S, the reaction is moderate, the exhaust volume is a little less than that of Example 1, the exhaust volume is moderate, and it drops slightly.

Embodiment 3

[0029] The emulsification time of Example 3 is about 16S, the reaction is moderate, and it is very slow when it is fast and stable. A large amount of foaming and exhausting, and a slight drop, until 2 minutes and 51 seconds before foaming and exhausting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com