Fabric surface defect detection machine set, and detection method

A defect detection and fabric technology, applied in optical testing flaws/defects, measuring devices, analyzing materials, etc., can solve problems such as affecting the accuracy of test results, low process maturity, affecting the detection effect, etc., to achieve convenient automatic labeling, Accurate detection results and the effect of online detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below through specific examples.

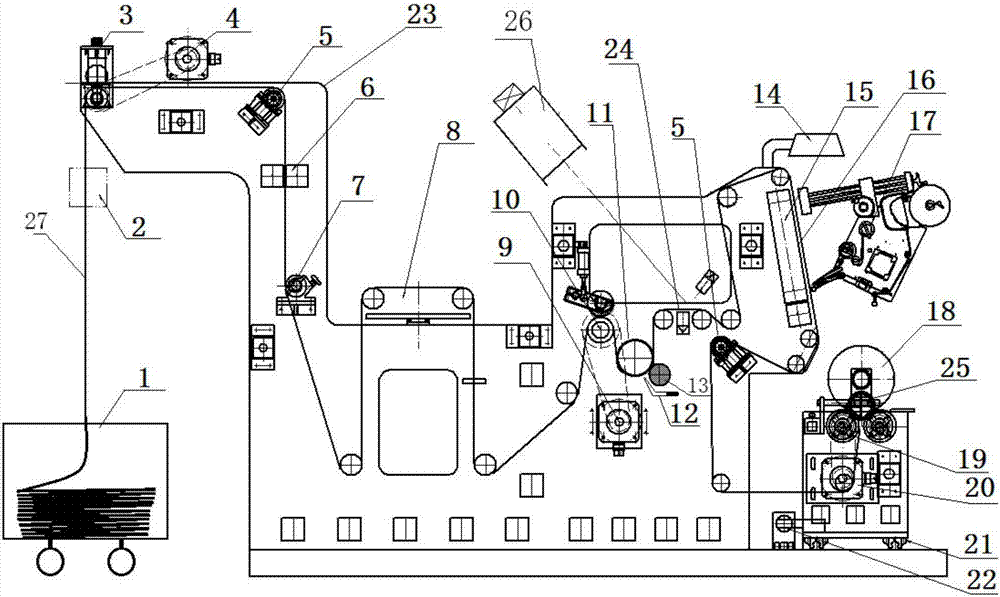

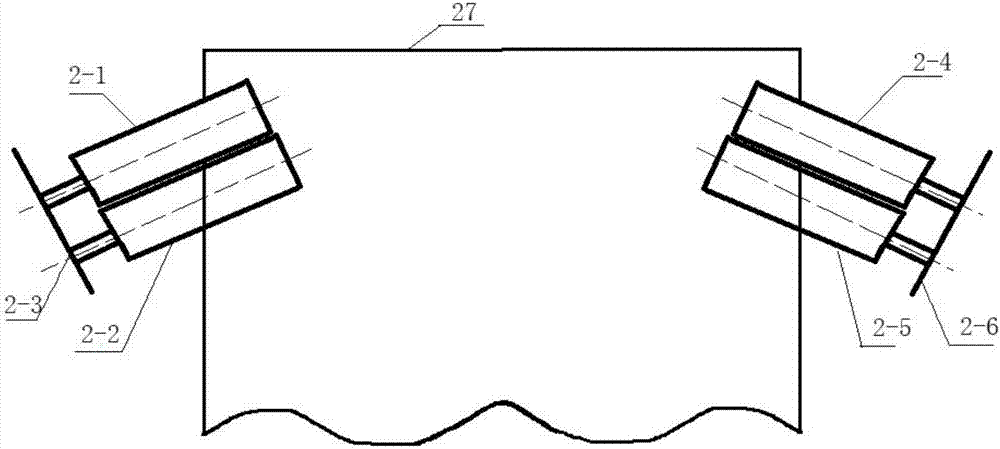

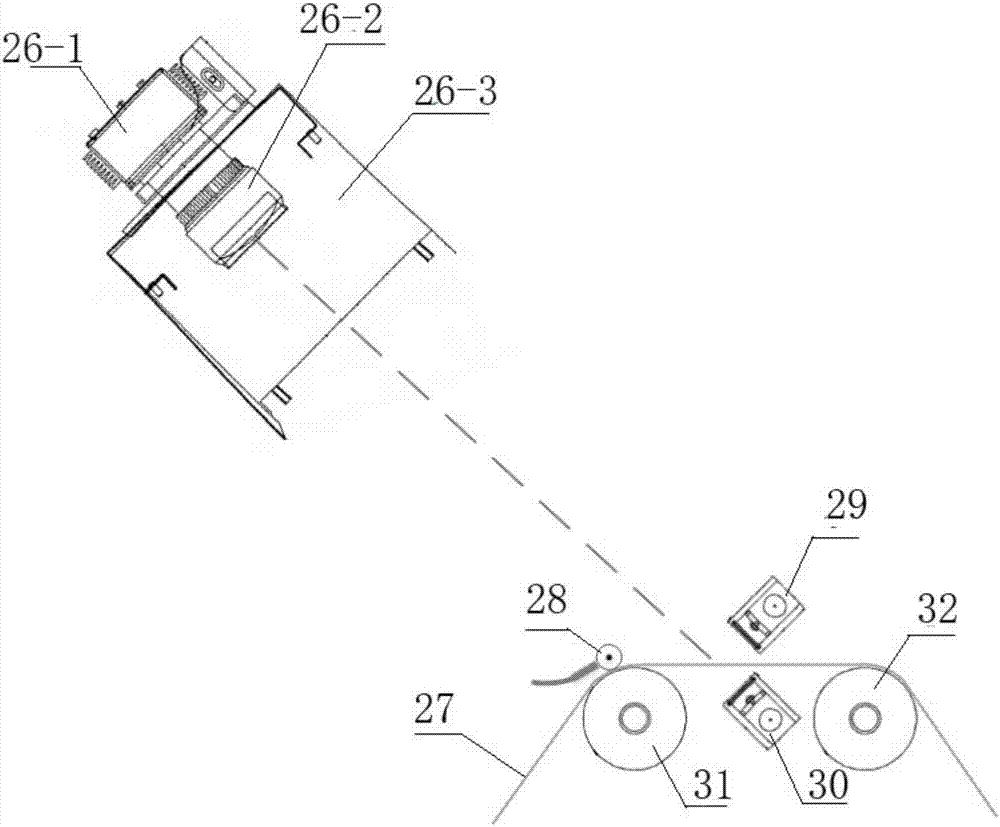

[0051] Such as Figure 1 to Figure 7 As shown, a fabric surface defect detection unit, the fabric surface defect detection unit can be used for online defect detection of fabric 27, generally used in the production process of worsted fabric 27, the yarn is turned into gray fabric through loom weaving After the inspection of the gray cloth, repairing the defects therein is cloth repairing. At this time, the fabric 27 is still a semi-finished product, and then passes through a series of finishing processes (comprising singeing, shearing, washing, boiling, drying, setting, Pressing, etc.) after processing, it is the finished product, and after the final inspection of the finished product, it can be packaged and shipped. The fabric surface defect detection unit can be used for the detection of semi-finished products, and can also be used for the detection of finished fabrics.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com