Intensive curing method and its application to reduce ash and black grains on leaves of Yuyan No. 7 tobacco

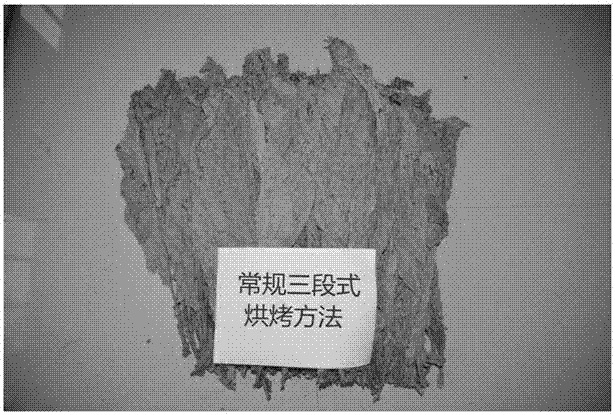

A technology of intensive curing and tobacco leaves, applied in the application, tobacco, preparation of tobacco and other directions, can solve the problem that the yield, quality and economic benefits have not achieved the expected effect of the variety, cannot adapt to the curing characteristics of Yuyan No. 7, and the curing of tobacco leaves. Unsatisfactory quality and other problems, to achieve the effect of facilitating the loss of water, increasing the income of tobacco farmers, and reducing the ash hanging on tobacco leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

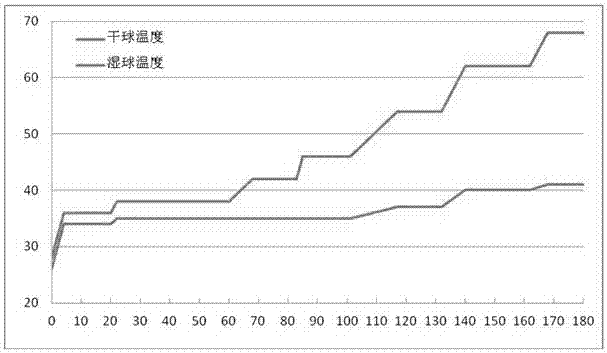

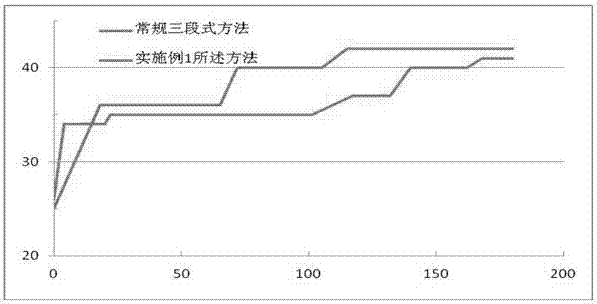

[0039] Use 5HR-160 fruit and vegetable drying equipment (i.e. heat pump dense air flow descending barn) to roast the mature and harvested middle leaves of Yuyan No. 7, and the tobacco leaves hanging on the high place are the upper shed tobacco, that is, the high-temperature layer Tobacco leaves, the tobacco leaves hanging in the lower place are the lower shed tobacco, that is, the low-temperature layer tobacco leaves, combined with the attached figure 1 ,Specific steps are as follows:

[0040] 1) In the early stage of yellowing, put the tobacco leaves on the kang and ignite the fire, raise the dry bulb temperature to 36°C at a rate of 2°C / h, keep the wet bulb temperature at 34°C, then bake for 16 hours, and set the operation mode of the barn damper to moisturizing , so that the tobacco leaves are fully sweated until the tip of the tobacco leaves in the upper shed turns yellow.

[0041] 2) In the middle stage of yellowing, raise the dry bulb temperature to 38°C at a rate of 1°C / ...

Embodiment 2

[0064] Use 5HR-160 fruit and vegetable drying equipment (i.e. heat pump dense air flow descending barn) to roast the mature and harvested middle leaves of Yuyan No. 7, and the tobacco leaves hanging on the high place are the upper shed tobacco, that is, the high-temperature layer Tobacco leaves, the tobacco leaves hanging in the lower place are the lower shed tobacco, that is, the low-temperature layer tobacco leaves, combined with the attached figure 1 ,Specific steps are as follows:

[0065] 1) In the early stage of yellowing, put the tobacco leaves on the kang and ignite the fire, raise the dry bulb temperature to 35°C at a rate of 2°C / h, keep the wet bulb temperature at 34°C, and then bake for 15 hours, and set the operation mode of the barn damper to moisturizing , so that the tobacco leaves are fully sweated until the tip of the tobacco leaves in the upper shed turns yellow.

[0066] 2) In the middle stage of yellowing, raise the dry bulb temperature to 37°C at a rate o...

Embodiment 3

[0073] Use 5HR-160 fruit and vegetable drying equipment (i.e. heat pump dense air flow descending barn) to roast the mature and harvested middle leaves of Yuyan No. 7, and the tobacco leaves hanging on the high place are the upper shed tobacco, that is, the high-temperature layer Tobacco leaves, the tobacco leaves hanging in the lower place are the lower shed tobacco, that is, the low-temperature layer tobacco leaves, combined with the attached figure 1 ,Specific steps are as follows:

[0074] 1) In the early stage of yellowing, put the tobacco leaves on the kang and ignite the fire, raise the dry bulb temperature to 36°C at a rate of 2°C / h, keep the wet bulb temperature at 33°C, and then bake for 16 hours, and set the operation mode of the barn damper to moisturizing , so that the tobacco leaves are fully sweated until the tip of the tobacco leaves in the upper shed turns yellow.

[0075] 2) In the middle stage of yellowing, raise the dry bulb temperature to 38°C at a rate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com